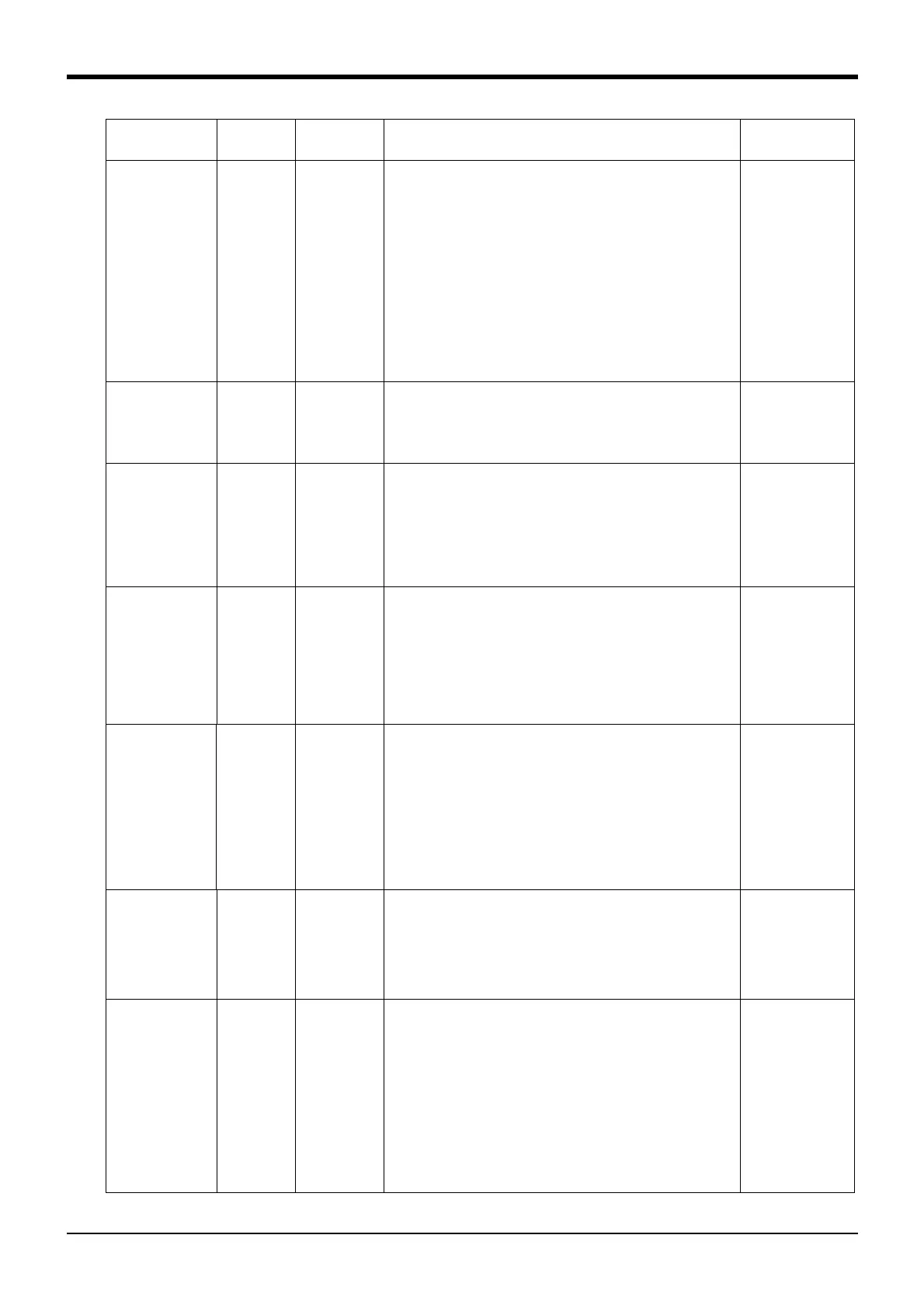

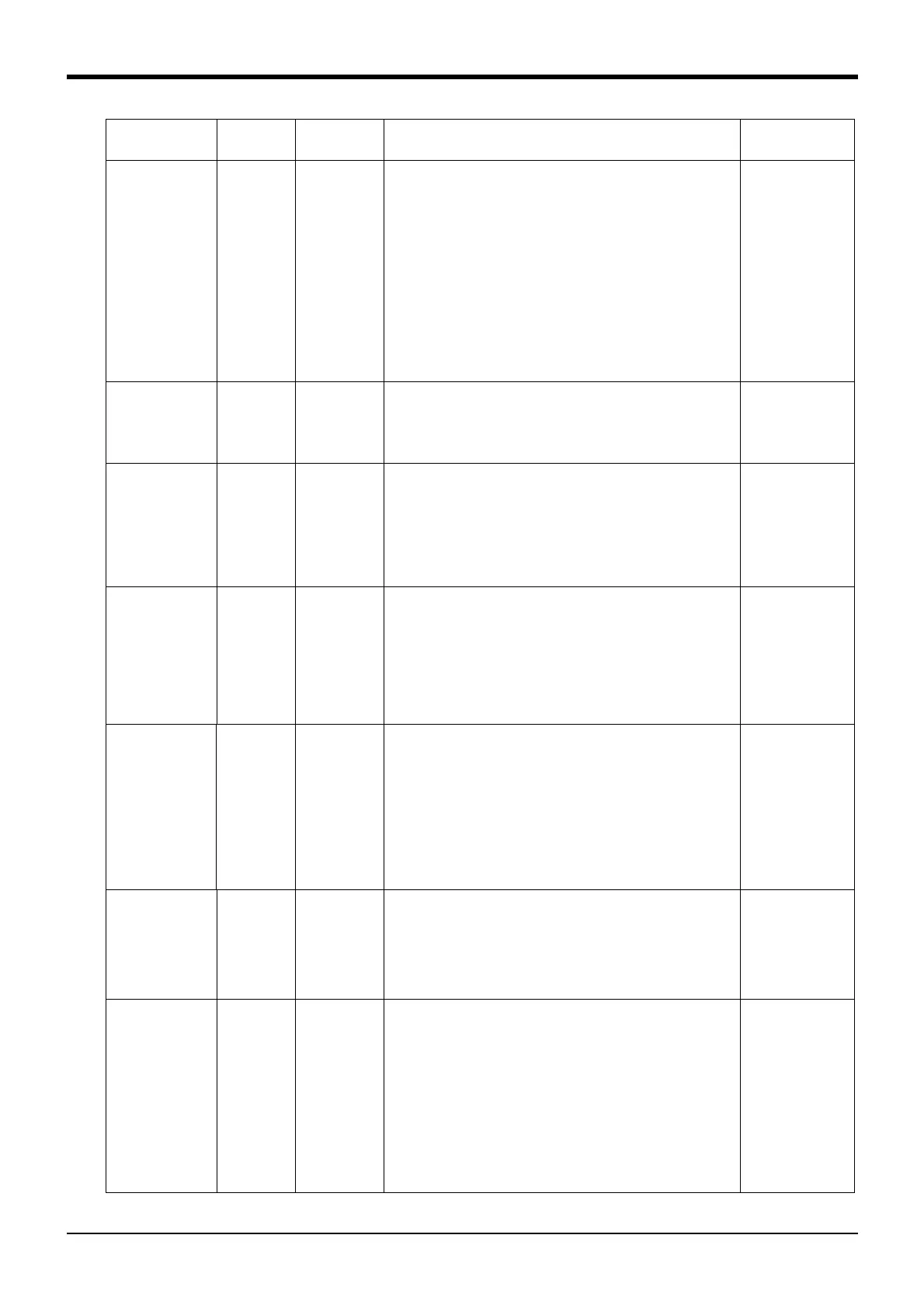

5Functions set with parameters

Movement parameter 5-449

Impact Detection

Note that this

parameter cannot

be used together

with the multi-

mechanism control

function.

COL Integer 3

Define whether the impact detection function can/cannot be

used, and whether it is enabled/disabled immediately after

power ON.

Element 1: The impact detection function can (1)/cannot (0) be

used.

Element 2: Enable (1)/disable (0) as the initial state at automatic

operation.

Element 3: Enable (1)/disable (0)/NOERR mode (2) during jog

operation

The NOERR mode does not issue an error even if impact is

detected. It only turns off the servo. Use the NOERR mode if it is

difficult to operate because of frequently occurred errors when

an impact is detected. The specification depends on the setting

for jog operation (element 3) in cases other than program

operation (including position jump and step feed).

RH-3FH/6FH/12FH/

20FH series:

1,0,1

RV-F series:

0,0,1

RH-3FHR series:

1,1,1

Detection level COLLVL Integer 8

Set the initial value of the detection level (sensitivity) of each

joint axis during automatic operation.

Setting range: 1 to 500, unit: % * If a value exceeding the setting

range is specified, the closest value allowed within the range is

used instead.

The setting varies

depending on the

model.

Detection level

during jog

operation

COLLVLJG Real value 8

Set the detection level (sensitivity) during jog operation

(including pause status) for each joint axis. Unit: %

Decrease the value to increase the detection level (sensitivity).

Increase the value if an impact detection error occurs even

though no impact is detected during jog operation.

Setting range: 1 to 500, unit: %

* If a value exceeding the setting range is specified, the closest

value allowed within the range is used instead.

The setting varies

depending on the

model.

Servo status after

collision detection

*Available soft-

ware versions

S/W Ver.

F-Q series:

R5 or later

F-D series:

S5 or later

COLSERVO Integer 1

Specifies the servo status after the collision detection. For this

function, using the impact detection in the NOERR mode is

required.

0: Servo off

1: Servo on held

0

Selection of wrist

rotation angle (axis

A) coordinate

system

RCD Integer 1

Switch the control and display method of the wrist rotation angle

(axis A of the XYZ coordinates system) of a vertical 5-axis type

robot. This parameter is invalid for robots of other types.

2: General angle method

Control axis A such that the hand's posture is maintained if

the value of axis A is the same before and after an operation.

Note that there are cases where the hand's posture cannot be

maintained depending on the attitude of the wrist (axis B of

the XYZ coordinates system). Under normal circumstances,

use this method without changing the setting at shipment from

the factory.

2 (general angle

method)

Warm-up operation

mode setting

WUPENA Integer 1

Designate the valid/invalid of the Warm-up operation mode.

0:Invalid

1: Valid

Note: If a value other than the above is set, everything will be

disabled.

Note: For multiple mechanisms, this mode is set for each

mechanism.

0(Invalid)

Warm-up operation

mode target axis

WUPAXIS Integer 1

Specify the joint axis that will be the target of control in the warm-

up operation mode by selecting bit ON or OFF in hexadecimal

(J1, J2, .... from the lower bits).

Bit ON: Target axis

Bit OFF: Other than target axis

A joint axis that will generate an excessive difference error when

operated at low temperature will be a target axis.

Note: If the bit of a non-existent axis is set to ON, it will not be a

target axis.

Note: If there is no target axis, the warm-up operation mode will

be disabled.

Note: For multiple mechanisms, this mode is set for each

mechanism.

0

Parameter

Parameter

name

No. of arrays

No. of characters

Details explanation Factory setting

Loading...

Loading...