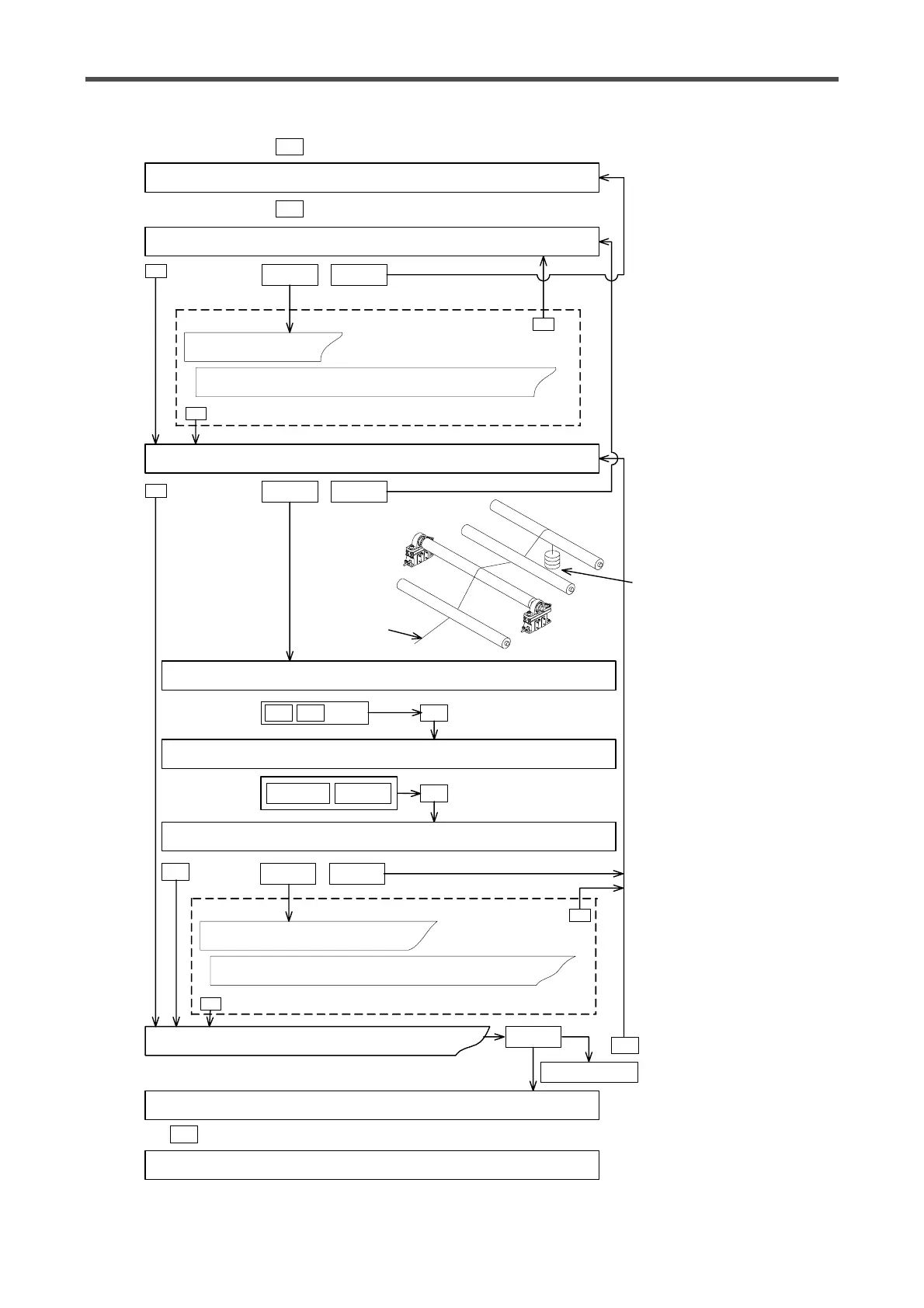

10

4.3 Adjustment of zero and span for tension detector

F L L S C A L E S E T T E N S I O N F U L L S C A L E

S E T → # # # # N : × 1 0 : × 1 : × 0 . 1

U

Z R O T U N E E X E C U T E T E N S I O N Z E R O T U N I N G

P U S H < E N T E R > O R < C A N C E L >

E

S A N T U N EP S E T N U M B E R O F T N S N . D E T E C T O R

T N S N . D T : T O W : O N L Y O N E

S A N T U N E E X E C U T E T E N S I O N S P A N T U N I N G

P U S H < E N T E R > O R < C A N C E L >

P

S A N T U N E S U S P E N D T E S T W E I G H T

W E I G H T → # # # # N S E T W E I G H T

P

S A N T U N E C O N T . T E N S I O N S P A N T U N I N G ?

P U S H < E N T E R > O R < C A N C E L >

P

S T T H E D R I V I N G P A R A M E T E R SE

P S S W O R D

S E T → # # # # # S E T N U M B E R

A

T

T

S

•

This is to set the full-scale

tension (maximum

mechanical tension) and the

number of display digits.

For example, if desired to

have "50.0N" displayed,

select " 500 " and " × 0.1 ".

• Zero adjustment should be

made with the tare weight of

the detection reel and

without material.

• If unable to make zero

adjustment, check the

system referring to pages 43

and 45.

• If the tension full scale is

changed, carry out the

zero/span adjustment again.

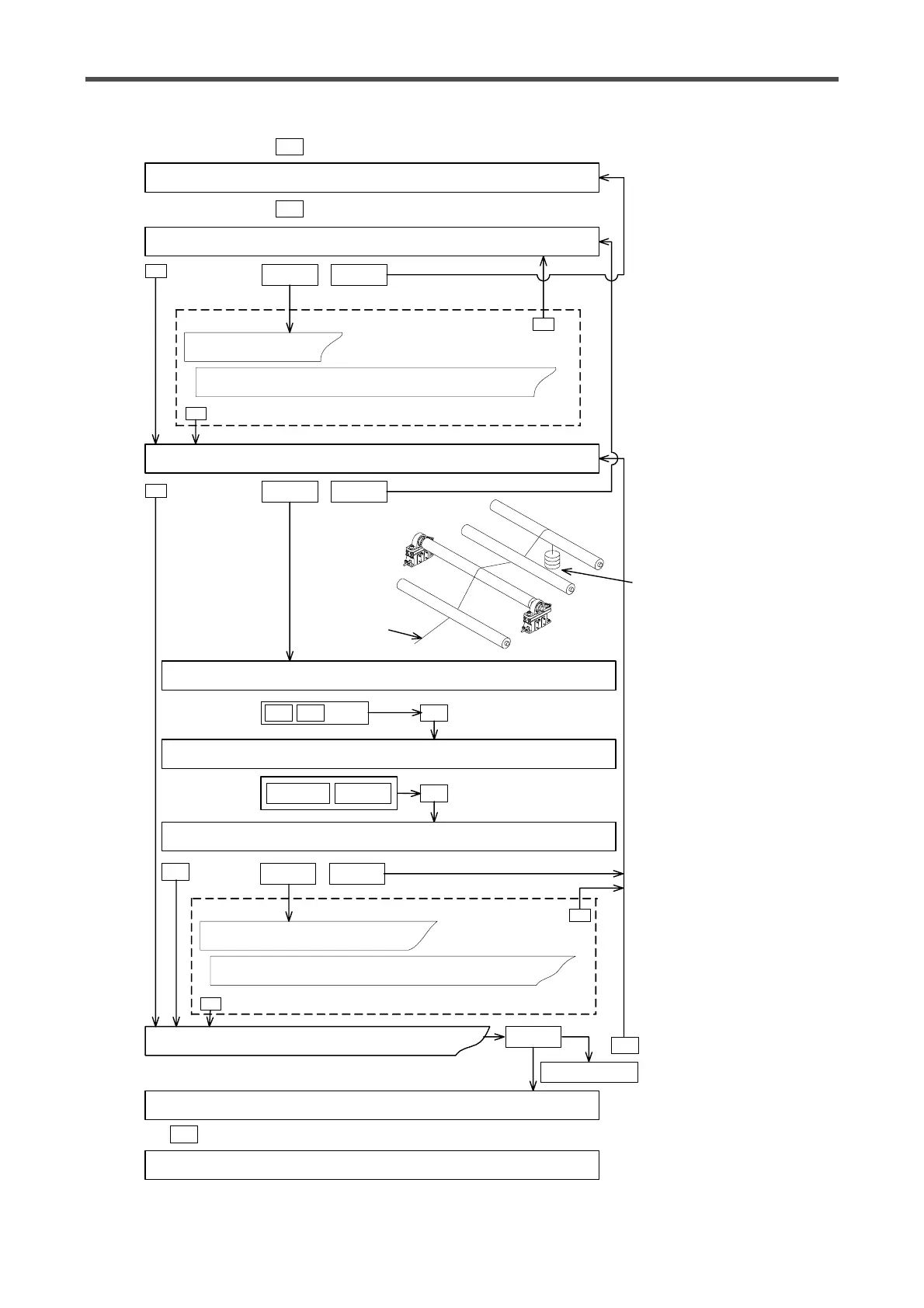

• Install the tension detectors

on both ends of the

detection reel as shown in

the left figure. For a short

detection reel, only one

tension detector may be

used. Use the following

screen to select one or two

tension detectors.

ENTER CANCEL

Stand- by(for approximately 10sec)

S

T

E R O T UZZ R O T U NE E - - - N I N G E R R O R

T H E D E T E C T I O N R O L L E R I S T O O H

Z R O T U NE

C M P L E T EO

E

!

Finished

Error

ENTER CANCEL

• Suspend weight W (N).

The weight should be a

static load as close to the

full-scale tension value as

possible

(Should be between 1 to 1/3

of the full scale).

Stretch a string

in the center of

the roller.

ENTER

WX T

ENTERNUMERIC

T

ENTER CANCEL

S

T

S A N T U N E C O M P L E T E !

L E F T → # # # # N :

P

P A N T USS A N T U NP E - - - N I N G E R R O R

S P A N T U N I N G T A R G E T W E I G H T I S

Error

Finished

T

C E C K C H E C K T H E P A R A M E T E R S

P U S H < E N T E R >

H

ENTER

Error Message

• When, for example, a mass

of 10 kg is suspended,

multiply it by the

gravitational acceleration

(9.8) to make it 98N.

• Do not alter the load during

the adjustment. Otherwise,

the system may not be able

to adjust or may generate

an error.

• By the display unit setting,

the system shows the value

in the magnitude of "N" or

"×10N". When one tension

detector is used, the left

display shows zero. When

two detectors are used, the

left and right readings are

balanced.

• When unable to adjust the

span, check the system

referring to pages 43 and

45.

• If an error message

appears, the system can

not complete the

adjustment. Set the

system again.

• Initial setting completed.

The system setting screen

appears hereafter. Set the

parameters as necessary.

T

T

T

Loading...

Loading...