44

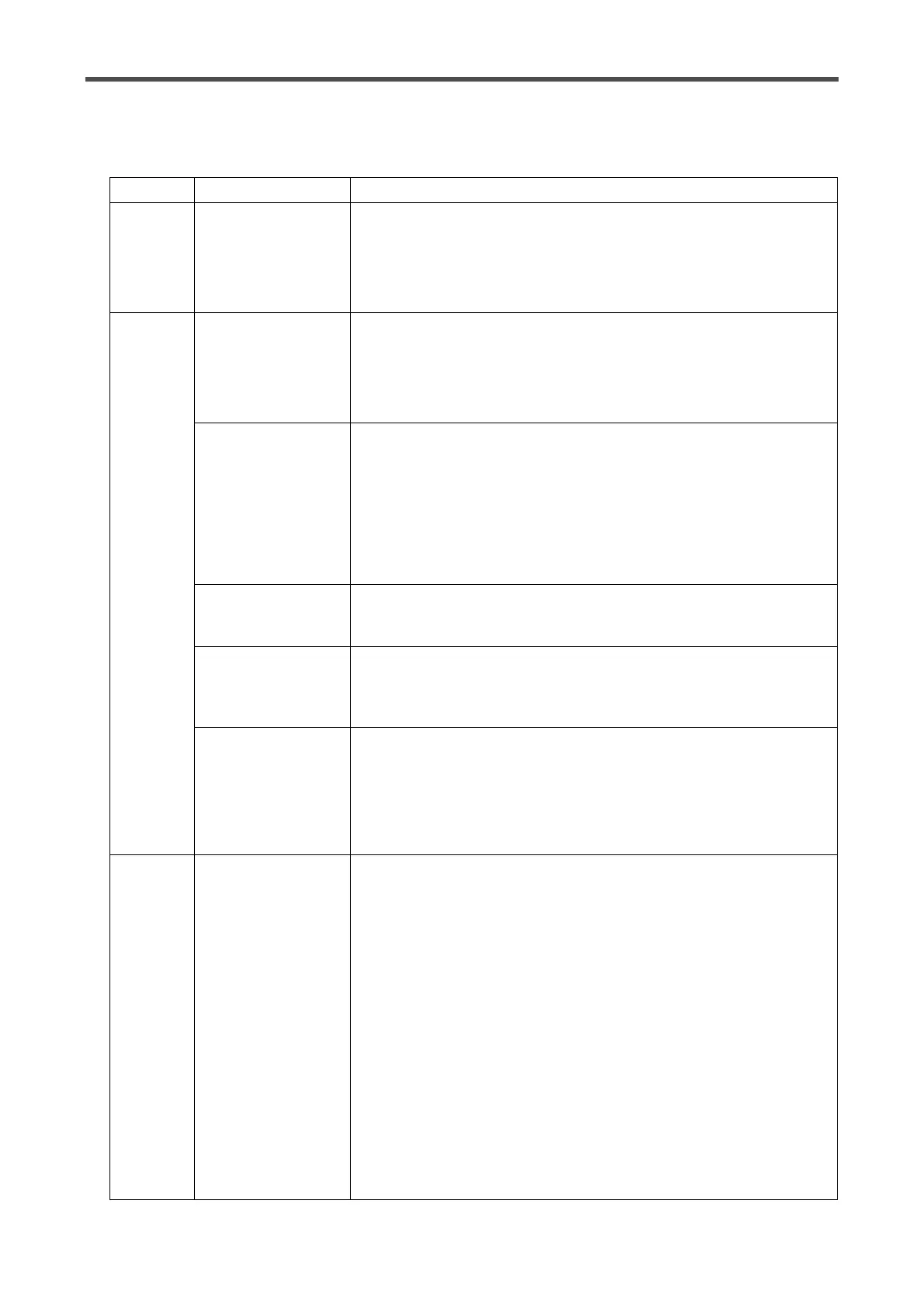

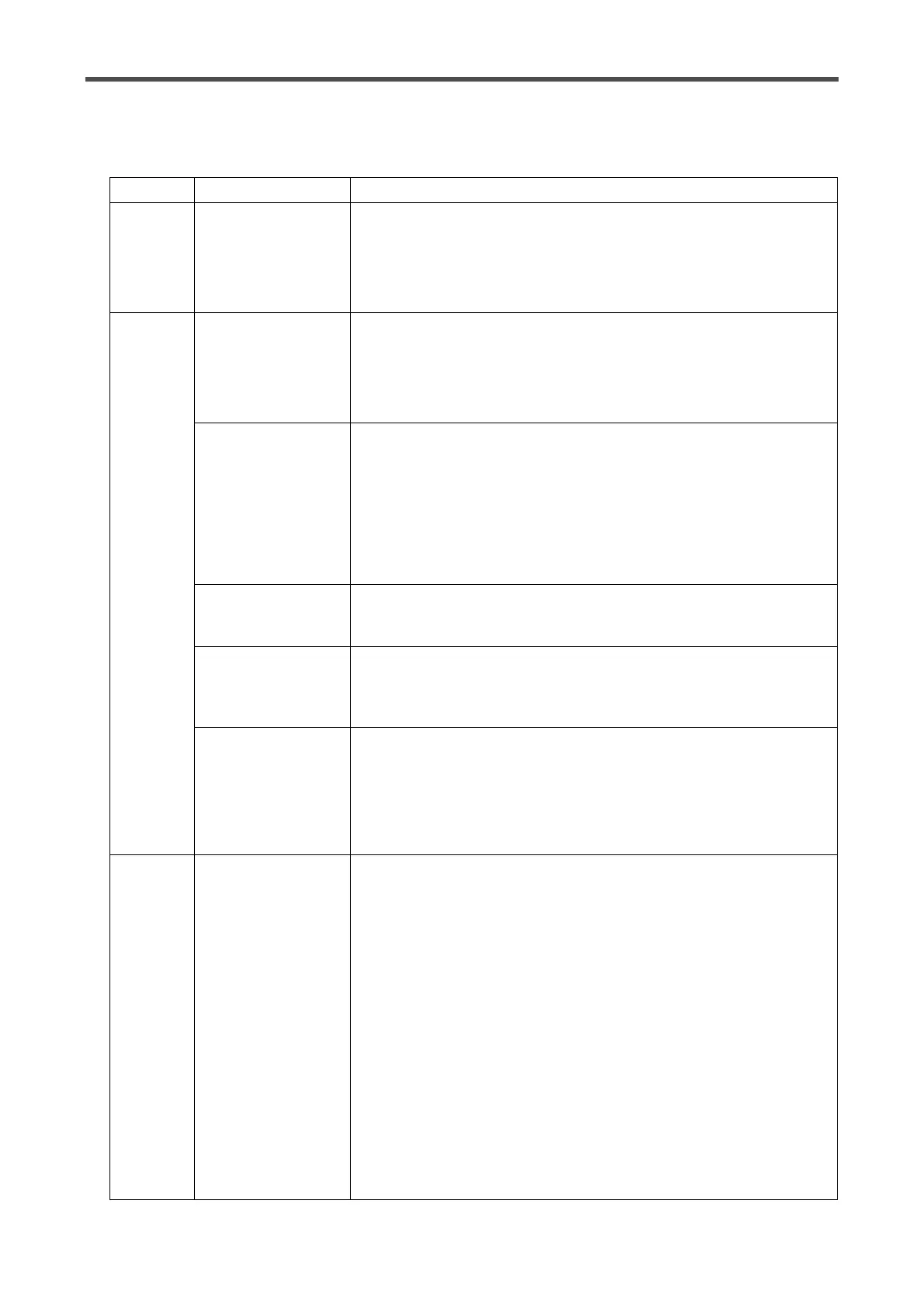

10.4 Unintended operation

Check the abnormality of the major components during trial operation and adjustment and during actual op-

eration using the following procedure.

Item Problem Disposal

Power

supply

When the POWER

switch is turned ON,

the POWER LED is

not lit.

•

Make sure the supply voltage between the terminals [PSL] and [PSN] is

100 to 240VAC (+10% to -15%), 50/60 Hz. If this value is not correct,

perform the correct wiring.

•

The fuse may be melted by insertion of foreign objects or abnormal loads.

If simply replacing the fuse may not solve the problem. Contact our ser-

vice department.

Tension

display

and

abnormal

tension

On the display, the

tension value or the

unit of the tension

flashes.

•

The tension signal from the tension detector is too high. The applied

load may exceed the rated load of the tension detector. Lower the ten-

sion set value.

•

Check the rated load of the tension detector. If no problem is detected,

increase the full-scale tension value. (After changing the full-scale ten-

sion value, be sure to tune the zero point and the span.)

When restarting after

stopping the mate-

rial, the tension read-

ing goes beyond the

scale from the begin-

ning.

•

Turn ON or OFF the [MC1] input signal depending on the run/stop status

of the machine . If the [MC1] input signal is kept at on status, restarting

operation may send out the maximum control output, and an extremely

high tension may be applied.

•

When stopping the machine, if the turning-OFF timing of the [MC1] input

signal is delayed, the control output may be extremely increased, and

an extremely high tension may be applied at starting operation. To pre-

vent this problem, be sure to turn OFF the [MC1] input signal when

stopping the machine.

The output increases

while the machine

halts.

•

The [MC1] input signal may not be turned OFF.

•

While the machine is stopped, be sure to turn off the [MC1] input signal.

After replacement of

the material, an

extremely high or low

tension is applied.

•

Check that the output set for the OFF status of the [RUN] input signal is

optimum for the reel diameter of the replaced material.

•

Reset the stall memory.

Fluctuating tension

control

•

Check whether similar fluctuations occurs during manual operation.

•

Fluctiations during manual operatinon is generally caused by changes in

tension as a result of machine vibration ,mechanical loss,etc. In this

case please check the machine.

•

If fluctuations do not occur during manual operation, this is generally

caused by high control gain set by the LE-40MTA-E tension controller.

In this case, please adjust the control gain factor refer to Sec. 7.5.

Actuator

Output cannot be

obtained in the man-

ual mode.

•

Make sure that the OUTPUT ON/OFF switch is turned on.

•

When 0 to 24 V output is obtained between the terminals [P] and [N] by

the manual torque setting, check the wiring to the powder clutch/brake.

When no abnormality is detected , the clutch/brake is defective or se

lected inappropriately.

•

If the output voltage is not obtained in the no-load condition when the

power is changed from off to on ,the LE-40MTA-E is defective.

If the short-circuit protection function between the terminals [P] and [N]

is actuated, the unit becomes the normal condition when the wiring is

corrected and the power is turned on again.

•

If 0

~

5V output is not obtained between the terminals[SA] and [SN] and

the terminals [NRO] and [AOC], remove the external load (1k

Ω

or more)

and check whether 0

~

5V is obtained.

•

If 4

~

20mA output is not obtained between the terminals [EAP] and

[EAN] , remove the E/P regulator (470

Ω

or less),connect the ammeter

between the terminals [EAP] and [EAN] , then check whether 4

~

20mA

output is obtained.

•

While the memory cassette is attached, the control output is not gener

ated.

Loading...

Loading...