45

Check the system as per the following procedure if the zero/span adjustment would not complete.

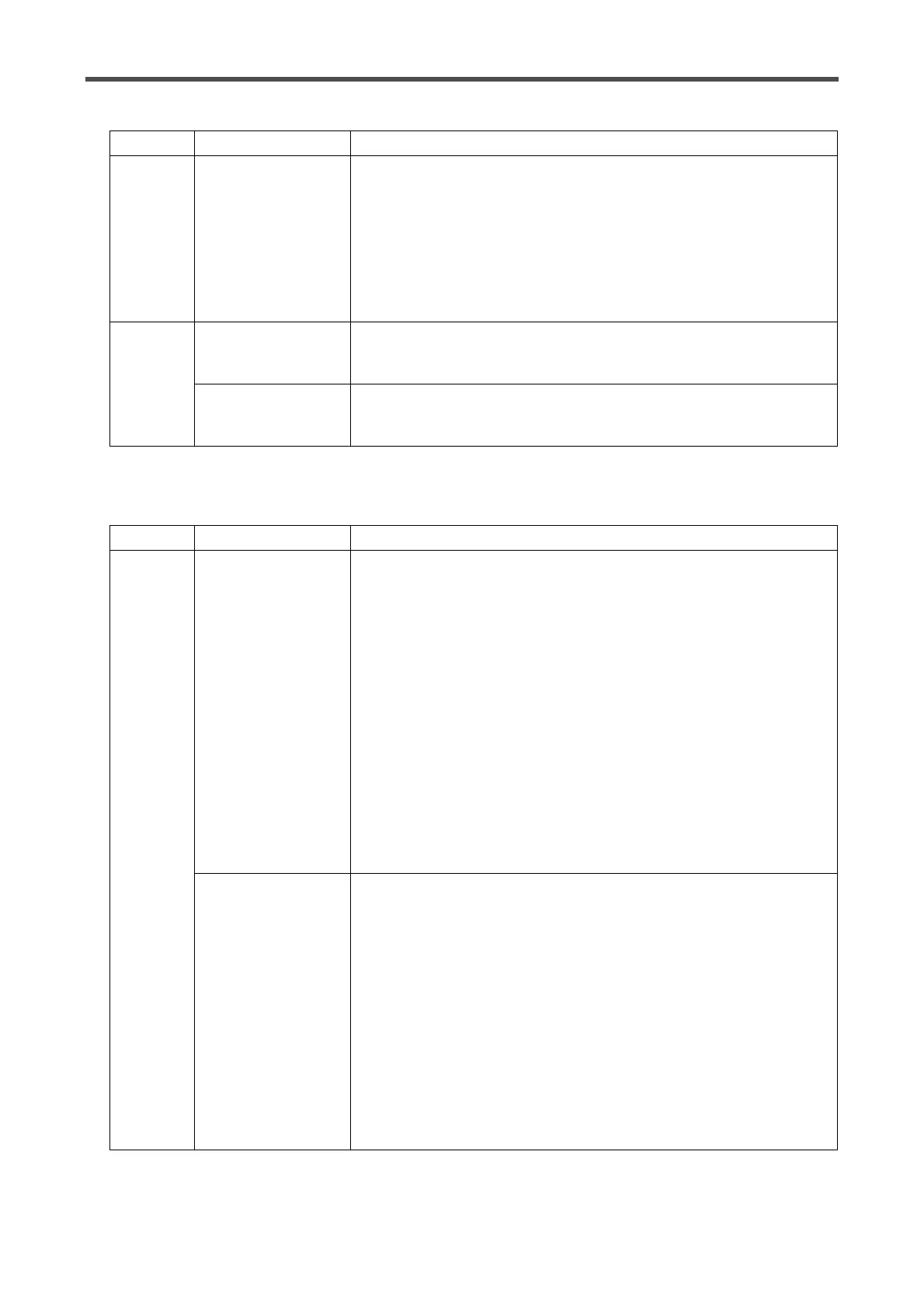

Item Problem Disposal

Input signal

The contact signal

and the analog volt-

age signal are not

input properly.

• Compare the ON/OFF status of the input contact signal with the sta-

tus shown on the monitor screen. In addition, check the input contact

for poor contact. If the input signal is properly turned ON and OFF

but the ON/OFF status is not displayed on the monitor, the LE-

40MTA-E tension controller is defective.

• Compare the voltage of the analog input terminal with the voltage val-

ue displayed on the monitor. Also check that noise is not influencing

the input line.

Others

Material gets loose

during acceleration

or deceleration.

•

The material tends to get loose if the acceleration/deceleration time is

too short or the material inertia is too high. Use gain 1 or gain 2 to

compensate the inertia during acceleration and deceleration.

Material is displaced

or gets too tight dur-

ing winding.

•

The taper control is recommended.

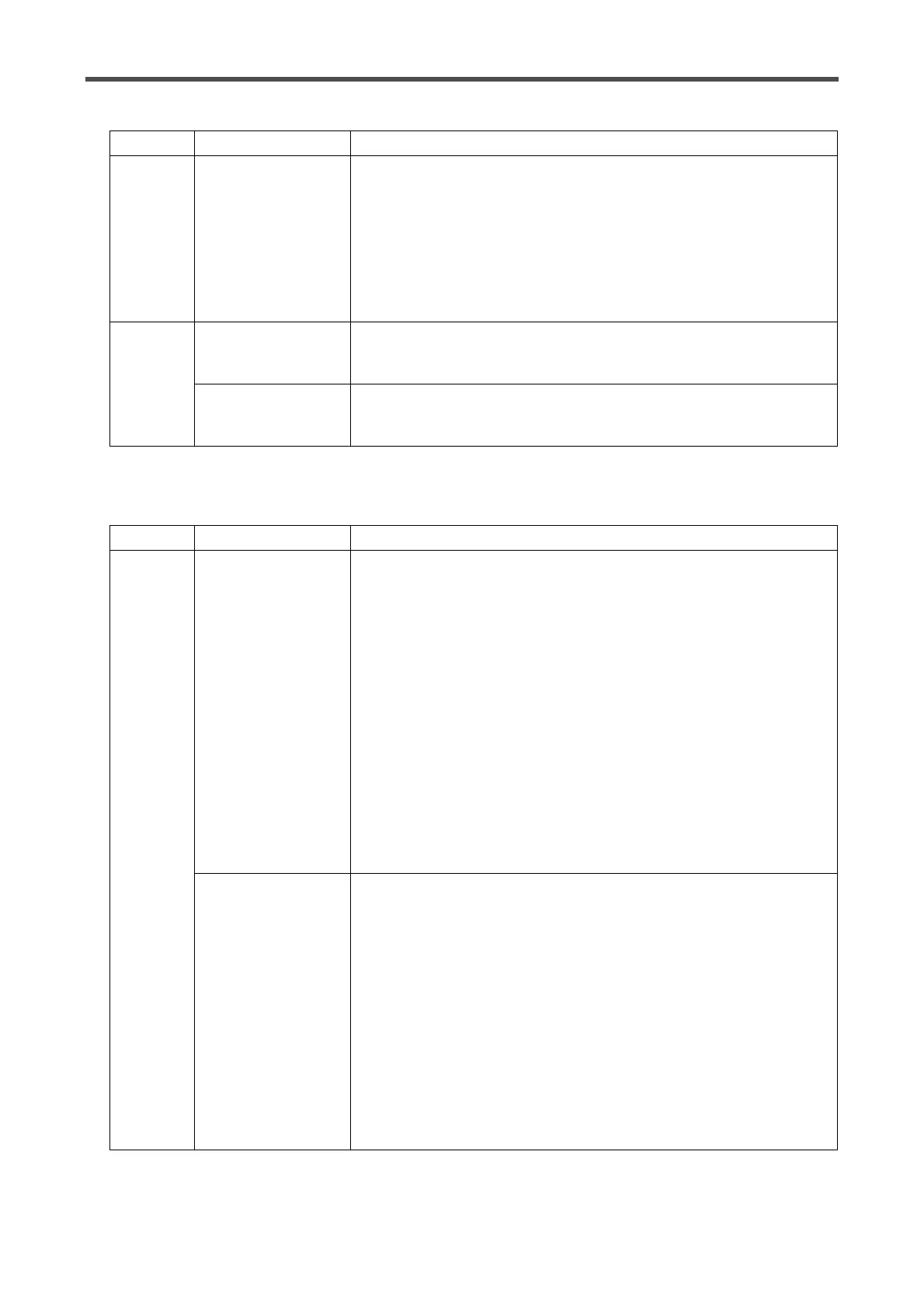

Item Problem Disposal

Tension

detector

Zero adjustment is

not possible.

Check the wiring in

accordance with

page 5.

• If the voltage between the terminals [RED] and [BLK] is not approxi-

mately 5.0 VDC, remove the wiring of this terminal and measure

the voltage. If the specified voltage is not obtained, the LE-40MTA-

E is defective.

If the specified voltage is obtained, the external wiring or tension de-

tector is defective.

• Remove the wiring in the tension detector.

Short-circuit the terminals [WHR] and [GRR] as well as the terminals

[WHL] and [GRL] . If zero adjustment is not possible still, the LE-

40MTA-E is defective.

• Connect the terminals [RED] and [BLK] exclusively to the tension de-

tec tor. If the voltage between the white and green cables in the ten-

sion detec tor is 120 mVDC (150mV DC x 0.8)or less with which the

current is not applied in the material and zero adjustment is not pos-

sible, the LE- 40MTA-E is defective. If the measured voltage ex-

ceeds 120mV, the tension detector selected is not appropriate .

(The tare weight is 80% or more of the rated load.)

Span adjustment is

not possible.

Check the wiring in

accordance with

page 5.

• Perform zero adjustment at first. Connect the terminals [RED] and

[BLK] exclusively to the tension detector. Measure the voltage be

tween t he wh it e a nd gr ee n c ables in the ten si on de tecto r.

• When span adjustment is not possible even if the difference between

the voltage measured when the material tension is set to 0 and the

voltage measured when the material tension is set to full scale value

is 30mV (150mVDC x 0.2) or more, the LE-40MTA-E is defective .

• When the difference in voltage is less than 30mV, the tension load ap-

plied on the tension detector is insufficient and the tension detector

selected is not appropriate. Even if the span adjustment is normally

completed, the tension detection error increases.

Use a tension detector having a less rated load.

• If the load is changed while the span is adjusted, adjustment may be-

come disabled .

Loading...

Loading...