24

6.8 Powder winding, two-reel switching

In the two-reel operation, the contacts inter-

locking with reel change are connected to

MC2. When this contact input changes from

ON to OFF or OFF to ON, the control output

is preset to the new reel preset value. When

the preset timer times up, the automatic con-

trol starts here. Interlock this signal with the

cutter operation. Switch SW1 at the same

time as SW2 and SW3.

For the preparatory drive of the new reel, turn

on the auxiliary power supply in a few sec-

onds but not later than 10 seconds immedi-

ately before switching the reels.

In the two-reel winding operation, the me-

chanical loss cancel torque MLA and MLB

are changed over. When it is OFF, the me-

chanical loss cancel value set to the reel A

becomes valid. When it is ON, the mechani-

cal loss cancel value set to the reel B is valid.

This is effective when the mechanical loss of

the reel A differs greatly from that of reel B.

See page 35.

For setting the new reel preset value and preset time, refer to Section 6.7 "Powder unwinding, two-reels

switching" on the previous page.

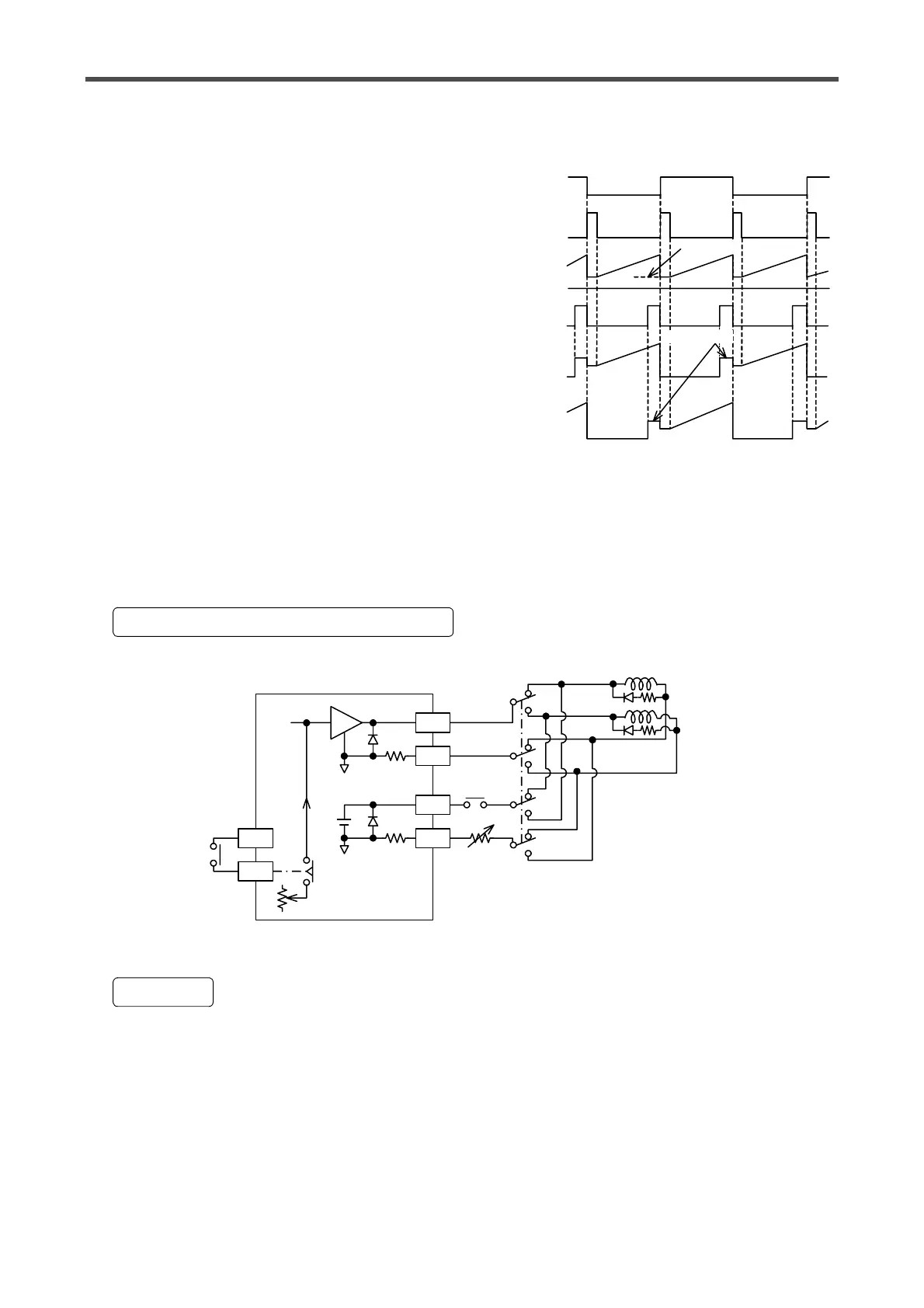

A reel A reel

B reel

New reel preset

MC2 input

Reel exchange

P-N

control output

Auxiliary

power output

PA (control output +

auxiliary power output )

PB (control output +

auxiliary power output )

PA and PB is control output for powder to A/B shaft.

Preset timer

Old reel stop

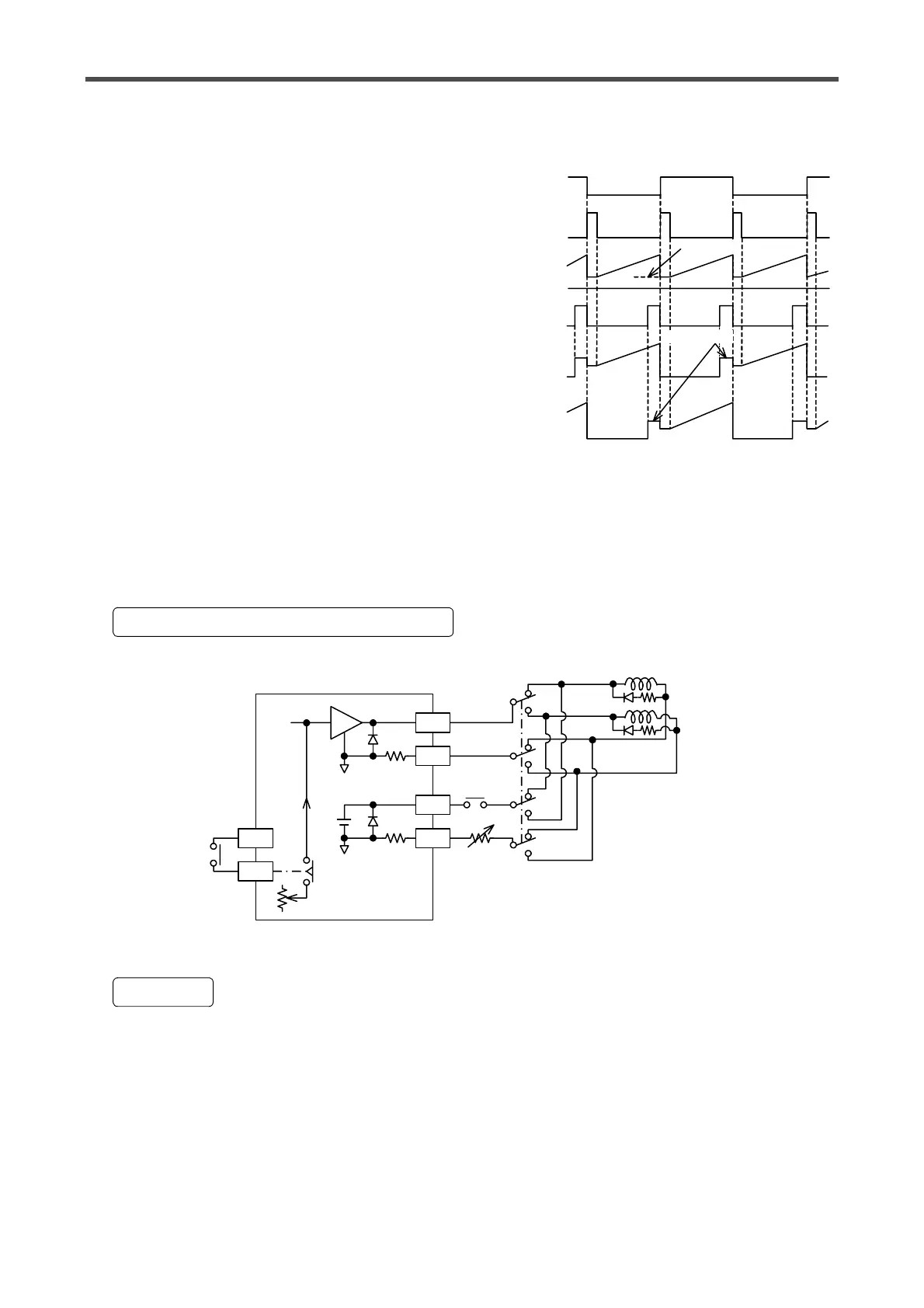

1. Connection of switch-over 2-reel powder

0.1Ω

MCC

MC2

S1

P

N

0.1Ω

Reel exchange

SW1

New reel

preset

Reel exchange

SW2

SW3

SW4

SW5

Predrive

torque

adjustment

PA

DA, RA

PA , PB : Powder clutch/brake

(hysteresis clutch/brake)

DA , DB : Commutation diode

200V,5A

RA , RB : Protection resistance

10W,47Ω

PB

DB, RB

S2

12V

2. Setting

Loading...

Loading...