28

7.3 Control of excessive winding tension

Such control as to increase/decrease the working tension, depending on the change in winding diameter

is called "Taper tension control", in which the tension is controlled in accordance with the preset pattern,

to suit the change in winding diameter. This function is mainly used to prevent the material from winding

too tight or too loose on the reel.

Following two methods are peresently available to determine the current reel diameter:

(1) By calculating internal reel diameter.

(2) By entering the reel diameter externally through analog voltage (high precision taper ten sion

control is possible).

In the internal reel diameter calculation, the reel diameter is calculated based on the torque control out-

put. Since it is not necessary to enter the reel diameter, the accuracy is not very high.

Two methods are available to set the taper ratio as follows :

(1) By setting the taper ratio (key entry) internally.

(2) By entering the taper ratio externally through analog voltage.

Two methods are available to enter the taper curves as follows :

(1) Linear line taper control.

(2) Non-linear line taper control.

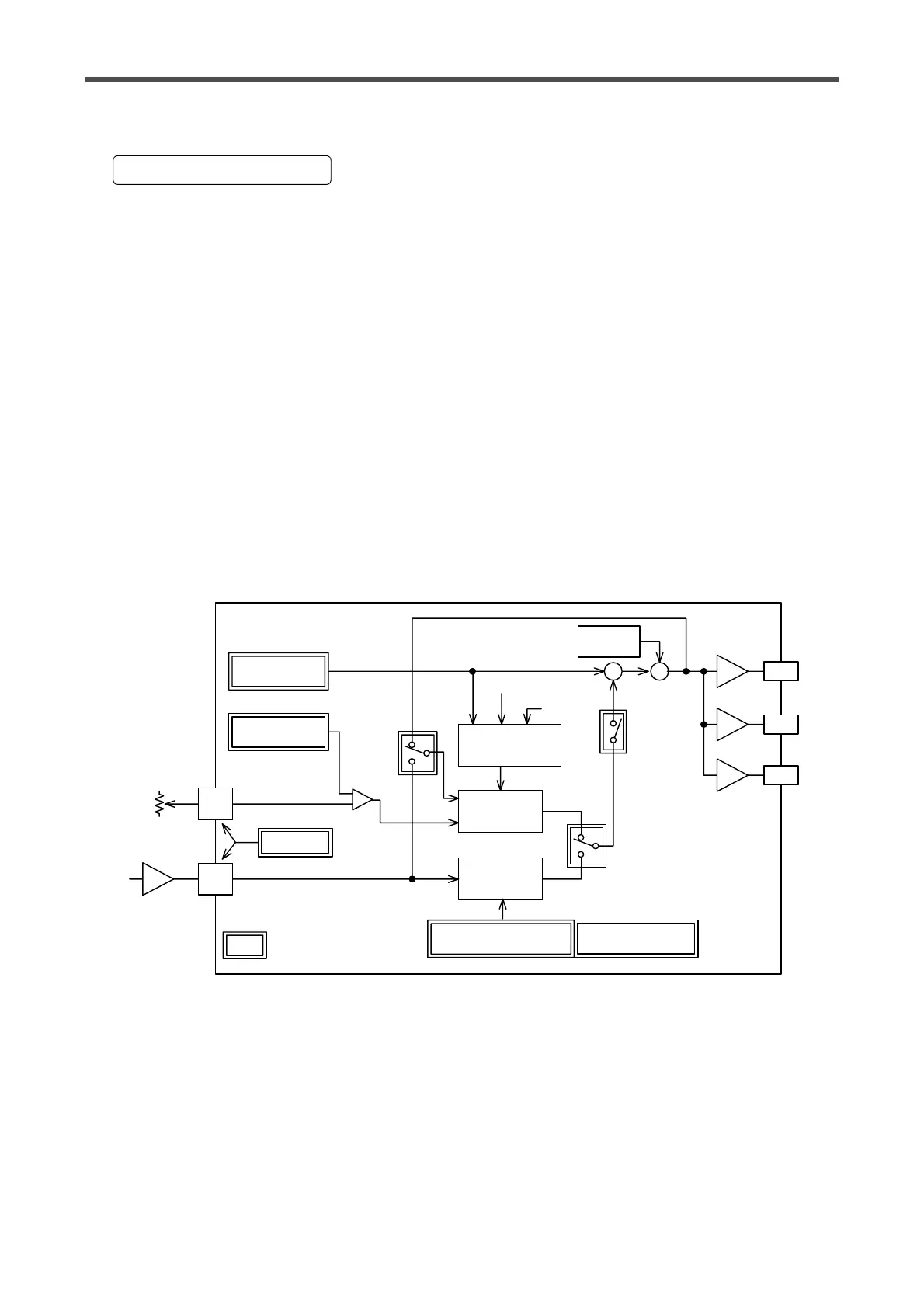

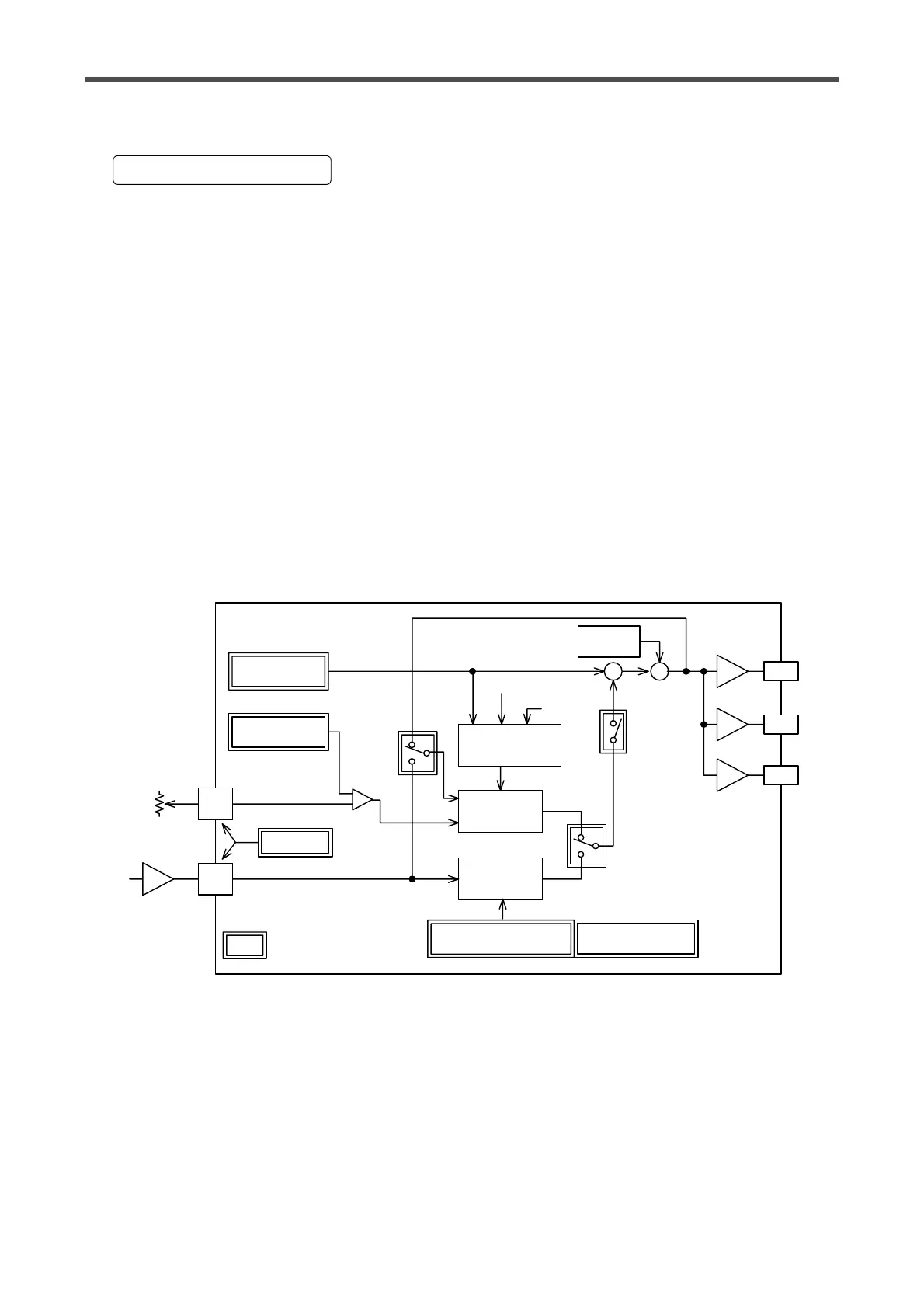

1. Outline of taper control

Calculation of

internal winding

diameter

Calculation of

linear line

taper

Calculation of

non-linear

line taper

-

Non-linear line

Linear line

Tension

detected

Torque control output

Data table corner 1~4

Taper 1~4

Minimum diameter

Maximum diameter

Internal

tension setting

Internal taper

ratio setting

Selection

P

SA

EAP

AI2

AI3

AI2

AI3 Reel diameter

Taper ratio

Taper reel

diameter

Inside

Outside

Taper to use

/Taper not

to use

Items in square are set

on the panel surface

External taper

ratio setting

External reel

diameter

Target

tension

+

Tension

detected

-

Torque

control output

Loading...

Loading...