156 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

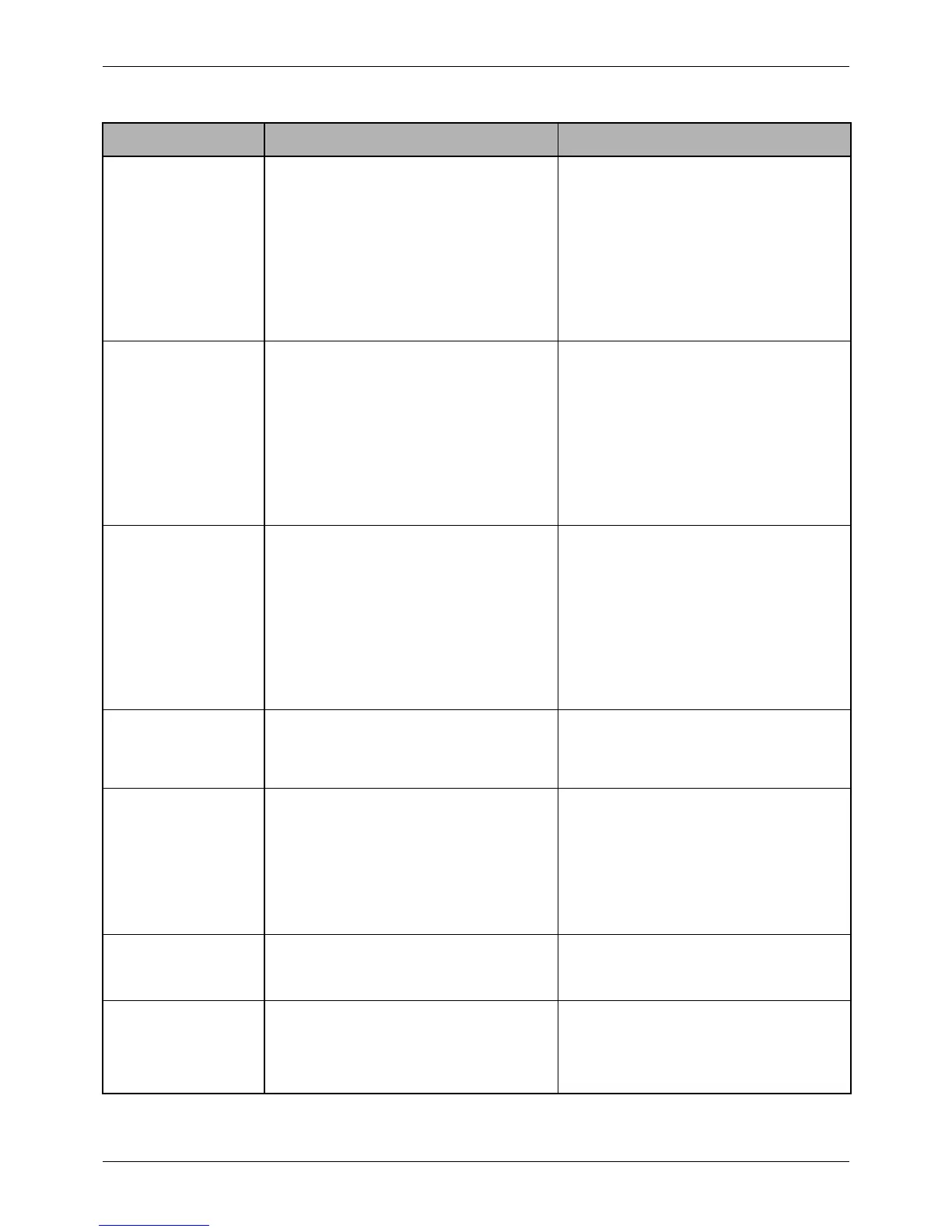

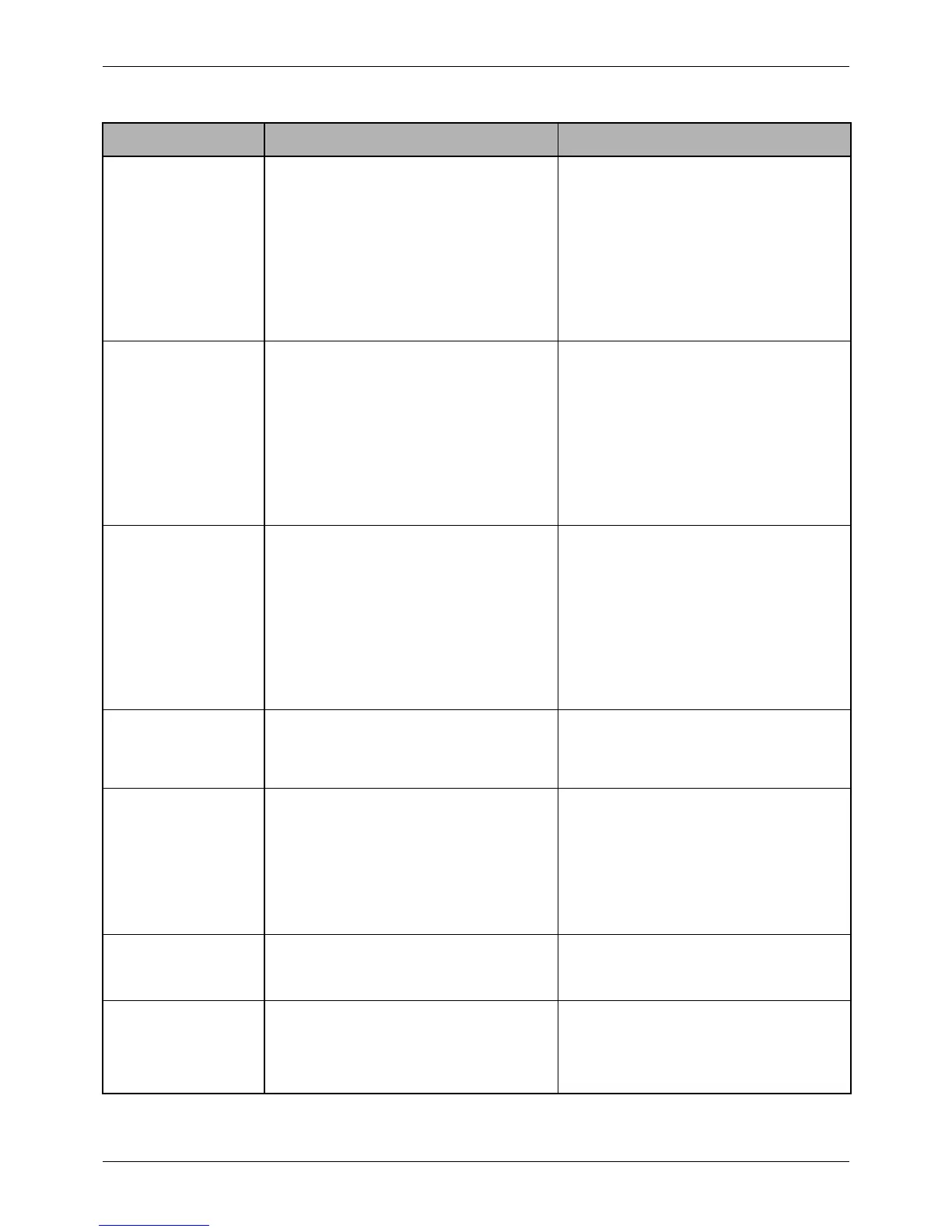

CAUSES OF ENGINE PROBLEMS AND

REMEDIES TROUBLESHOOTING

Causes Details of Causes Remedies

Fuel is not supplied to

injection pumps properly

Fuel tank supply valve is closed Open the valve.

No fuel in tank Add fuel.

Fuel lines restricted Repair or clean fuel pipes with compressed air.

Air in fuel system Tighten mounting sections or replace fuel pipes.

Fuel leakage Retighten connections.

Fuel filter is clogged Clean or replace filter element.

Inadequate air bleeding Conduct air bleeding.

Irregular injection pump

operation

Sticking of plunger(s) Disassemble and replace parts.

Worn plunger(s) Disassemble and replace parts.

Worn bearing(s) Disassemble and replace parts.

Damaged plunger spring(s) Disassemble and replace parts.

Loose plunger pinion(s) Reinstall by matching marks.

Delivery valve(s) defective Replace parts.

Damaged delivery valve spring(s) Replace parts.

Insufficient fuel injection

volume (by injection pump)

Catching of governor stop lever link Repair link properly and set lever to neutral position.

Control rack does not move Supply lubricant, or disassemble and repair.

Seizing of plunger(s) Disassemble and replace parts.

Worn plunger(s) Disassemble and replace parts.

Worn bearing(s) Disassemble and replace parts.

Loose plunger pinion(s) Reinstall by matching marks.

Full-load setting of governor does not move Readjust governor setting on bench.

Excessive fuel injection

volume

Stop lever sticking in “increase” position Repair link properly and set lever to neutral position.

Full-load setting of governor improper Adjust governor setting on bench.

Loose plunger pinion(s) Reinstall by matching marks.

Fuel injection nozzle(s)

defective

Seizing of nozzle tip needle Repair or replace.

Nozzle tip seat(s) defective Repair or replace.

Damaged nozzle spring(s) Replace parts.

Fuel injection pressure is too low Change adjusting shim and set standard injection

start pressure using nozzle tester.

Carbon deposits on packing at nozzle tip(s) Remove carbon deposits.

Fuel injection timing is too

advanced

Faulty mounting angle of injection pump Tilt injection pump toward outside of engine and

adjust timing.

Timing gears incorrectly installed Correct timing gear engagement.

Fuel injection timing is too

retarded

Faulty mounting angle of injection pump Tilt injection pump toward outside of engine and

adjust timing.

Timing gears incorrectly installed Correct timing gear engagement.

Worn fuel injection pump bearing Replace parts.

Loading...

Loading...