68 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE ENGINE MAIN PARTS

10.2.2 Connecting rods

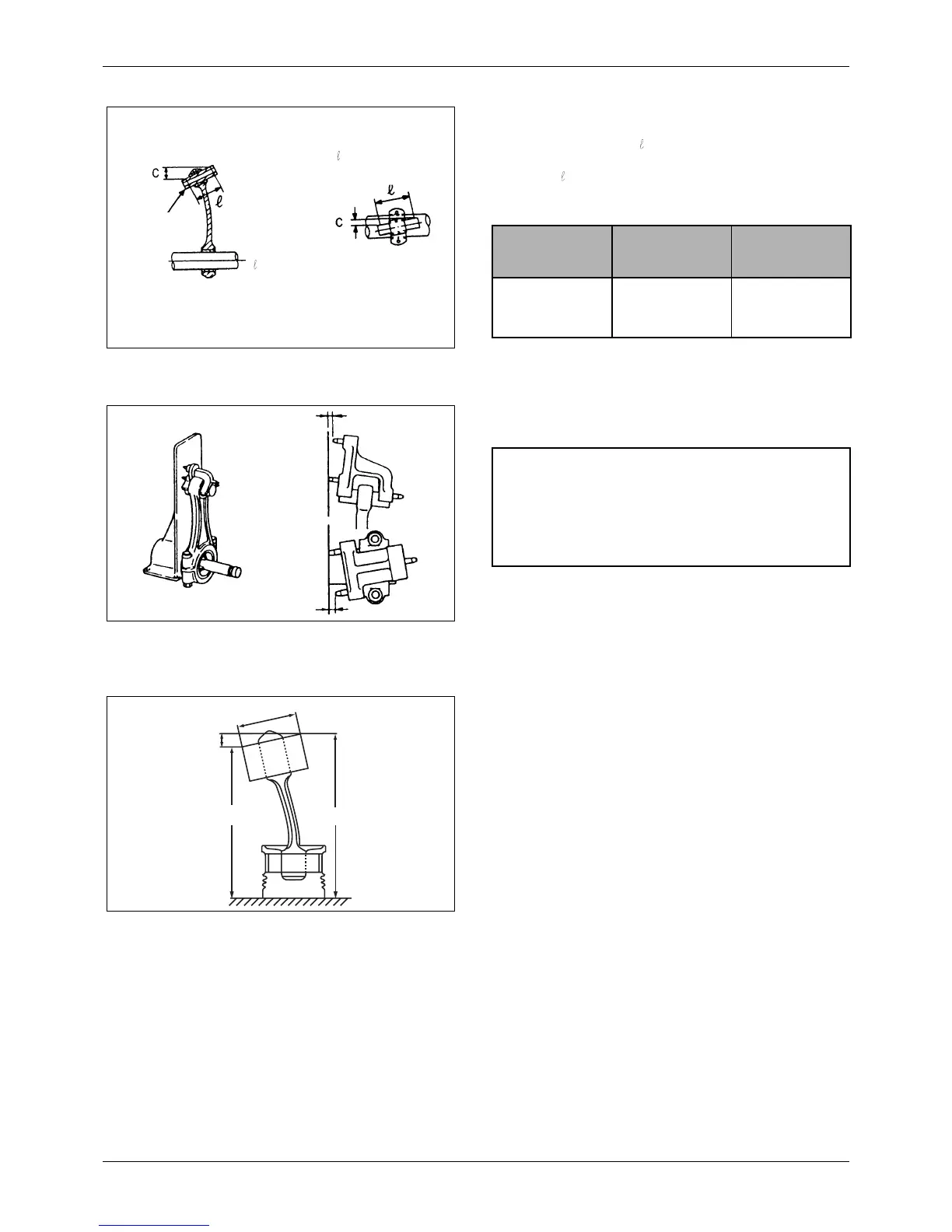

1. Measure “C” and “ ”. If the measurement at C is

larger than 0.05 mm [0.0020 in.] per 100 mm [3.94

in.] of

, straighten the rod with a press.

Unit: mm (in.)

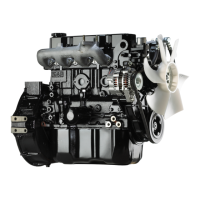

2. A connecting rod aligner is generally used for

checking the connecting rod for twist and bend.

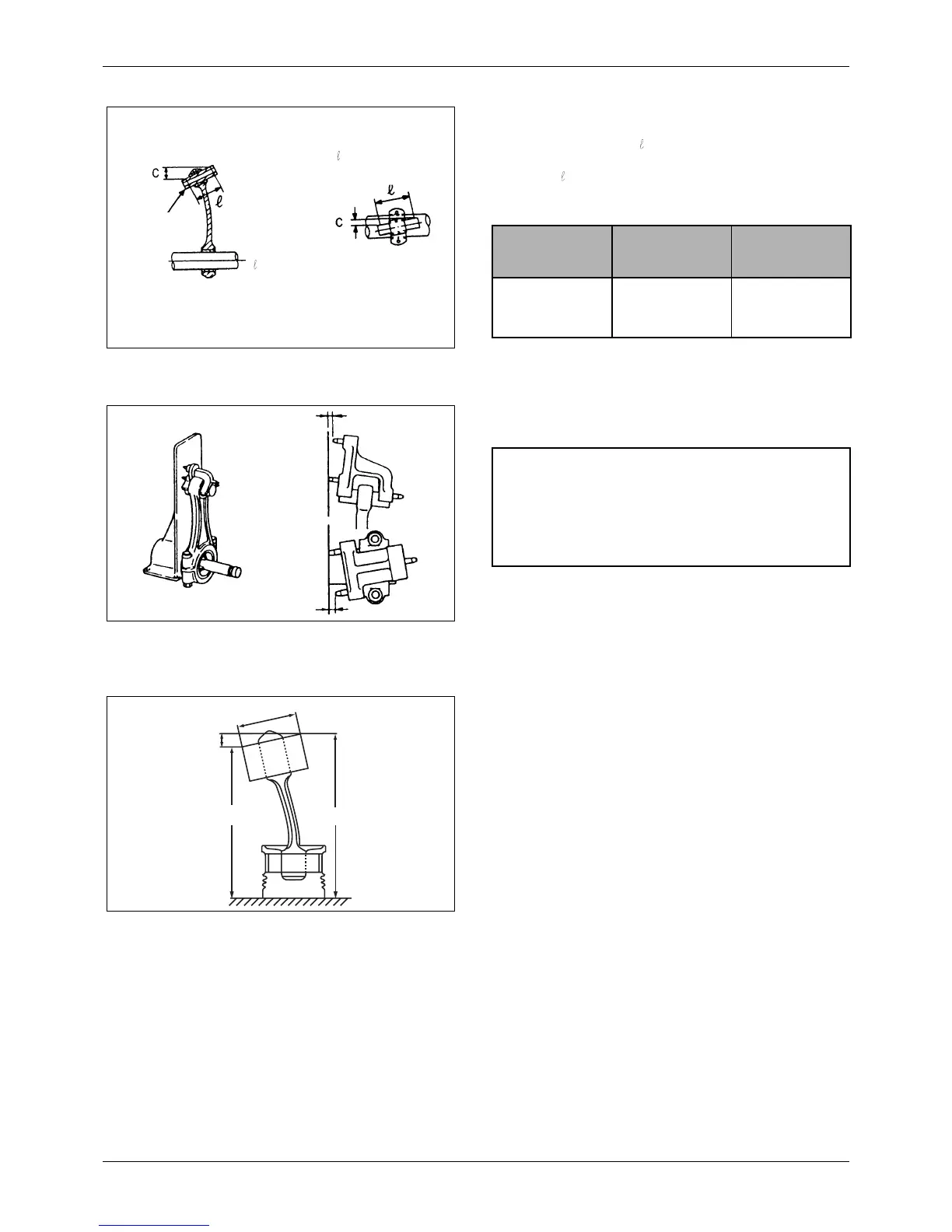

3. When the measurement is taken with the piston

installed to the connecting rod, place the piston

upside down on a surface plate, insert a round bar

having the same diameter as the crank pin, and

measure the height of the round bar using a dial

gage.

Figure 115 Inspecting connecting rod

Twist

Bend

Piston pin

C

----

0.05 (0.0020)

100 (3.94)

-----------------------------------

<

C

----

0.05 (0.0020)

100 (3.94)

-----------------------------------

<

Unit: mm (in.)

Item Nominal Value

Assembly

Standard

Connecting rod

bend and twist

0.05/100

[0.0020/3.94] or

less

0.15/100

[0.059/3.94]

Figure 116 Checking connecting rod with a

connecting rod aligner

NOTE

To check the connecting rod for bend, install the cap

to the rod and tighten the cap nuts to the specified

torque.

Figure 117 Checking connecting rod with a dial

indicator

AB

C

D

Loading...

Loading...