40 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

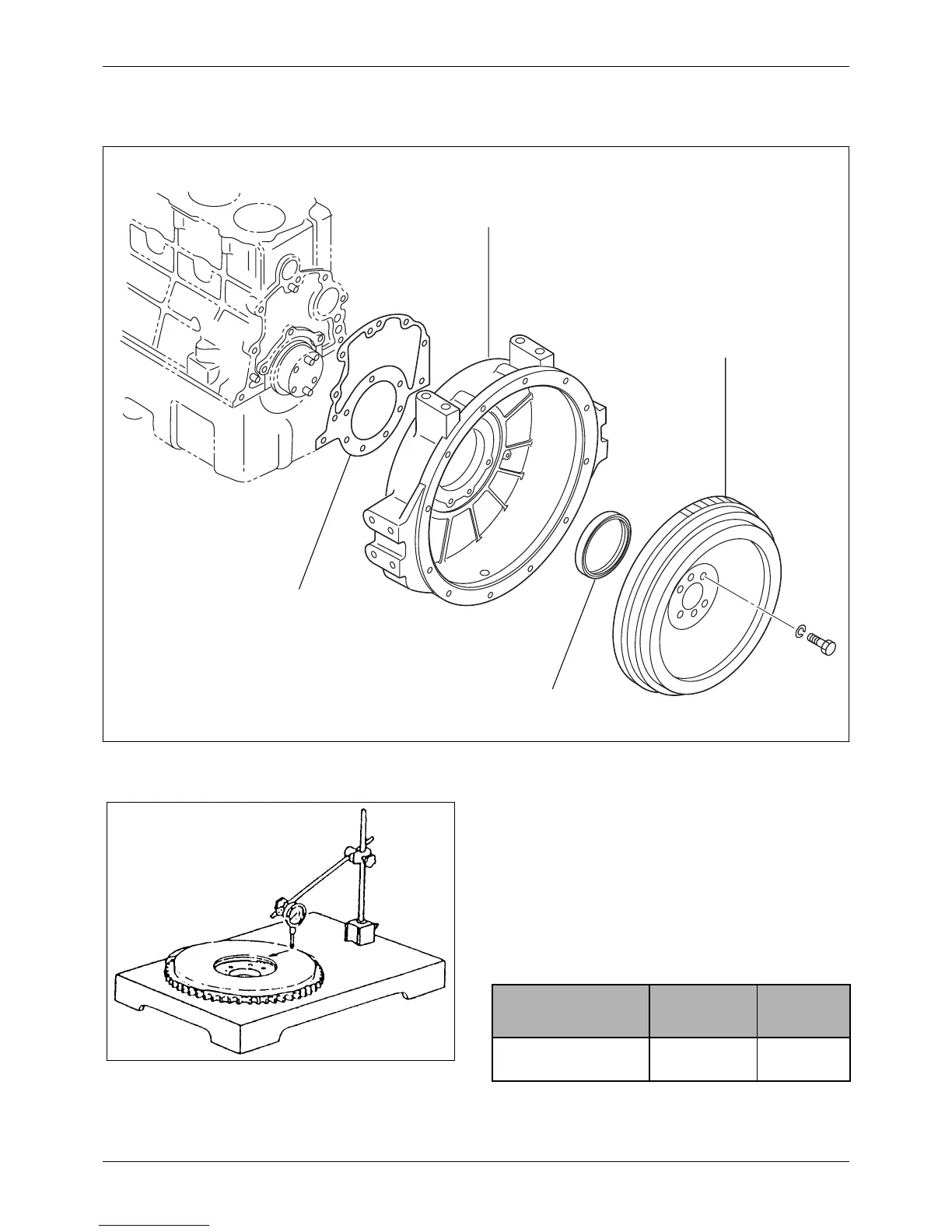

FLYWHEEL ENGINE MAIN PARTS

8.2 Inspection

8.2.1 Flywheel and ring gear

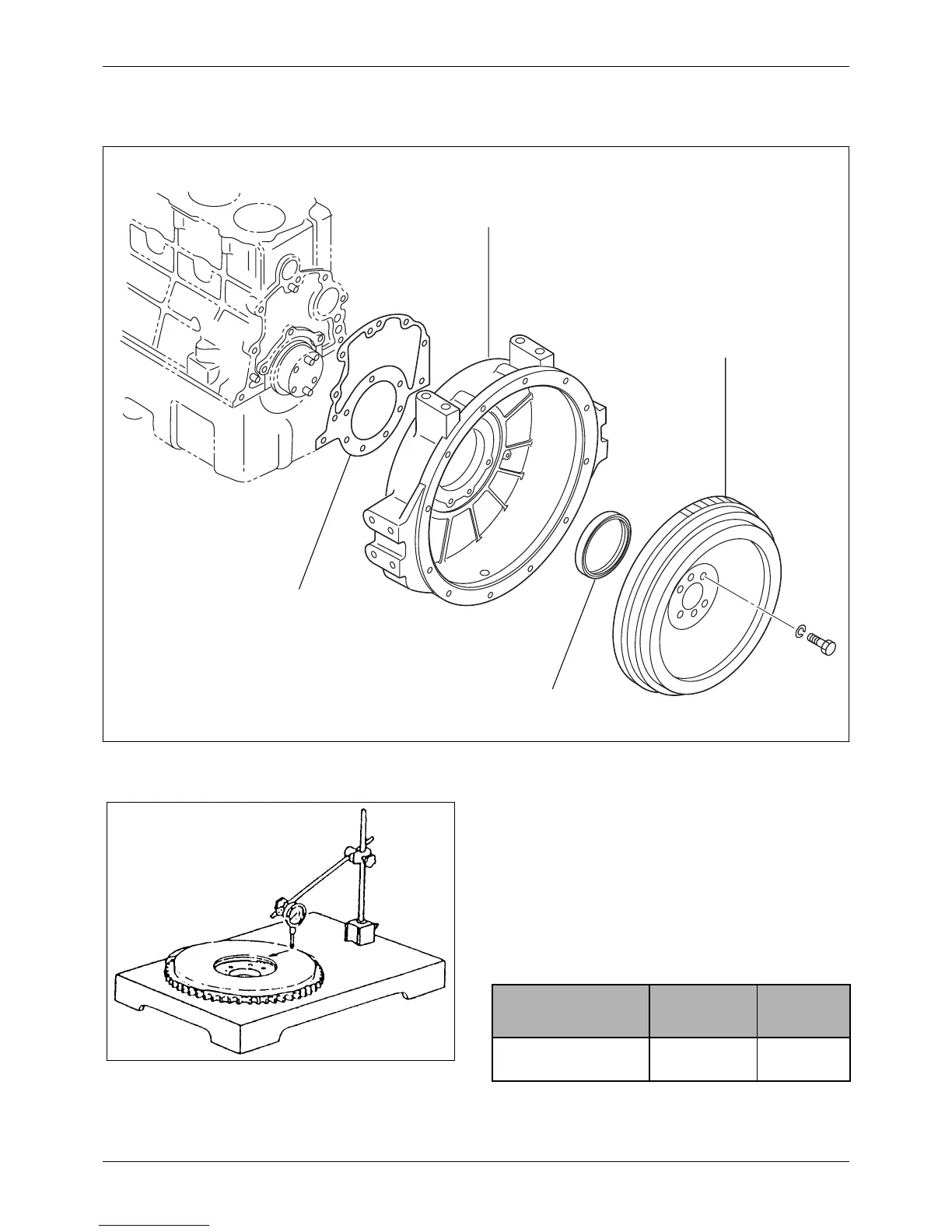

1. Flatness of flywheel

Put the flywheel on the surface plate. Set a dial

indicator at one side of the friction surface and

move it over to the opposite side of the surface, as

shown in the illustration. If the friction surface is not

flat over the repair limit, regrind it.

Unit: mm [in.]

Figure 51 Inspection points

Check for cracks or

defective dowel holes.

Check friction surface for cracking

scoring, or other defects that affect

serviceability. Examine ring gear for

worn or defective teeth.

Replace

Replace

Figure 52 Checking flywheel

Item

Assembly

Standard

Repair

Limit

Flatness of flywheel

0.15 [0.0059]

of less

0.50

[0.0197]

Loading...

Loading...