64 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

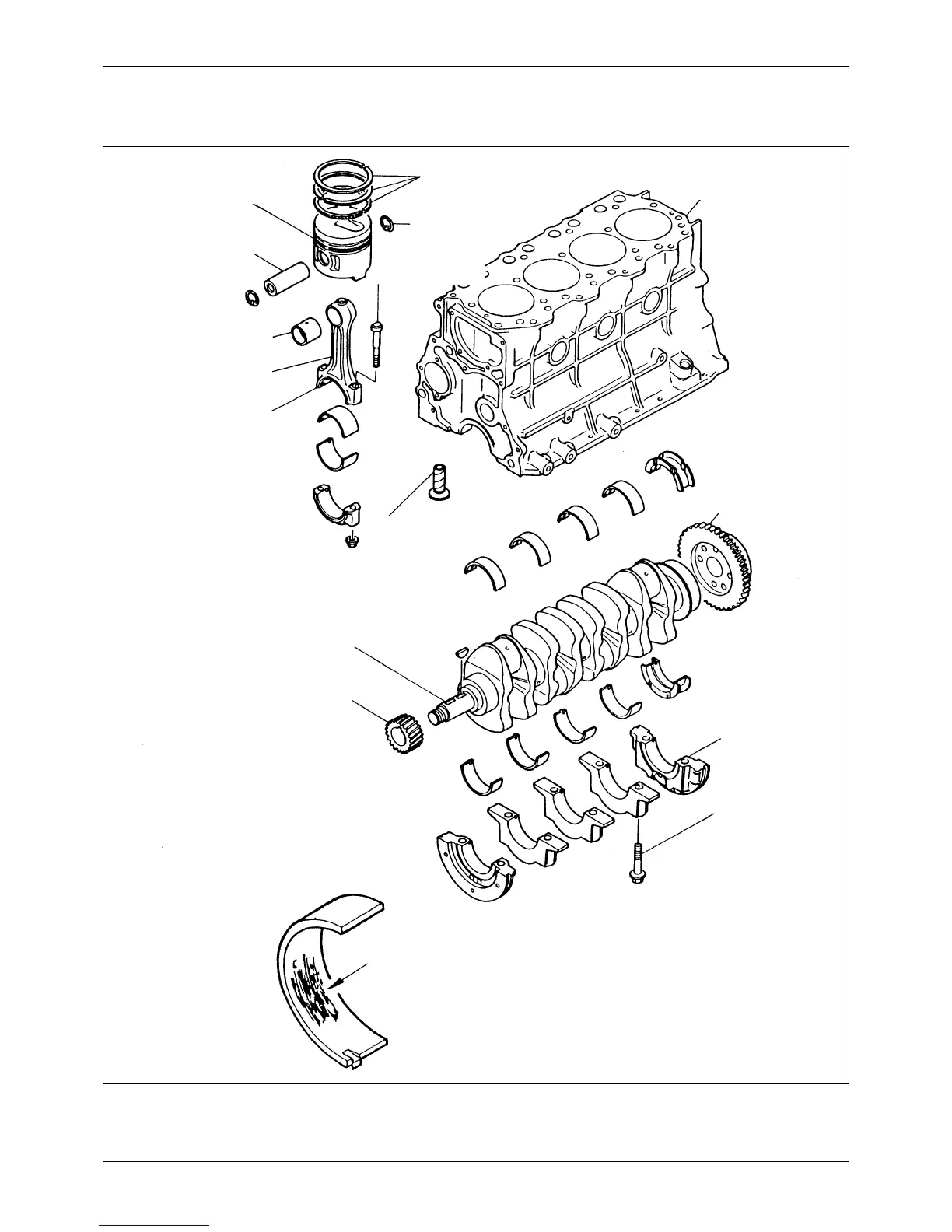

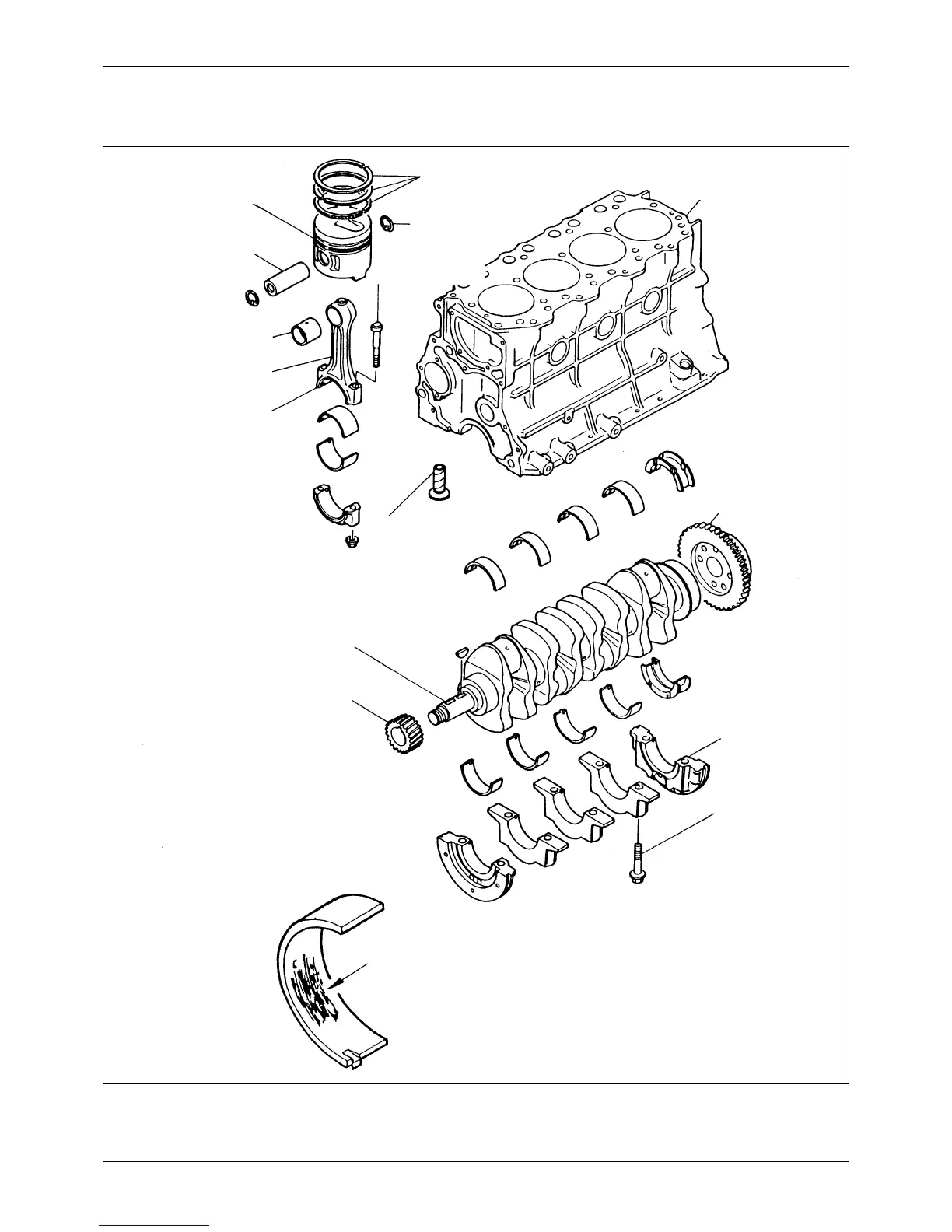

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE ENGINE MAIN PARTS

10.2 Inspection

Figure 107 Inspection points

Check for fatigue

Check for wear.

Check for wear or

clogged hole.

Check for cracks or

clogged oil hole.

Check for serrated

portions for wear or

cracks.

Check for wear.

Check for wear, score

marks, cracks or

carbon deposits.

Check for

stripped

threads

Check for wear or damage.

Check for cracks, clogged oil

hole or other defects.

Check for nicks, chipping or

abnormal tooth contact.

Typical failures for which main bearings are to be checked are scratches

due to dirt embedded into bearing material, loss of overlay due to lack of oil,

craters or pockets due to fatigue failure, failure due to poor seating, radius

ride, etc.

Check for cracks.

Check for stripped

threads.

Check for scale

deposits, corrosion or

other defects.

Loading...

Loading...