66 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE ENGINE MAIN PARTS

2) Install a new piston rings and recheck the

clearance. If the clearance still exceeds the

service limit, replace the piston.

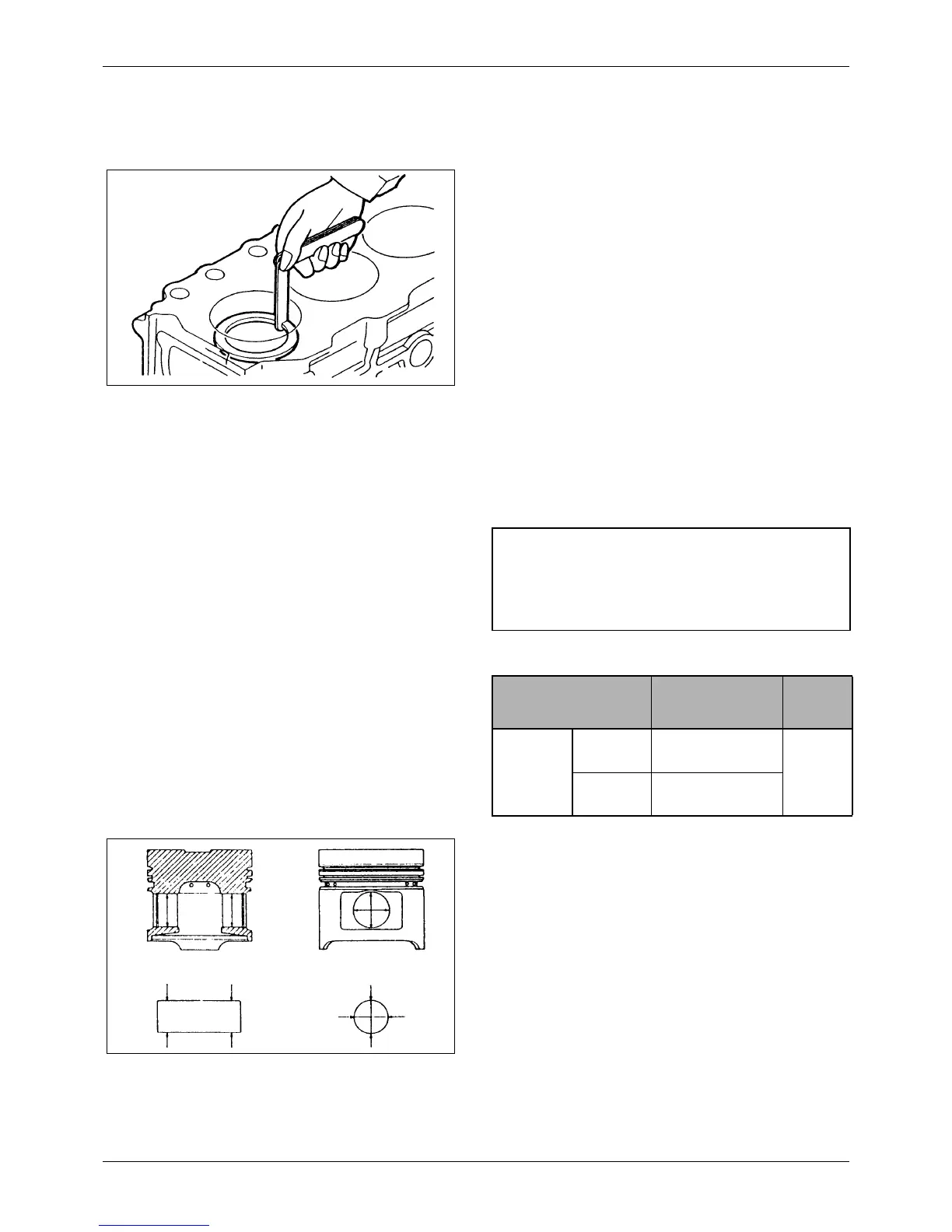

3. Checking clearance between ends of piston ring

Install the piston ring in a new cylinder or a gage

and measure the clearance between the ends of

the ring with a feeler gage. If the clearance

exceeds the service limit, replace all piston rings.

Inside diameters of gages

Standard gage:

88 mm [3.46 in.]

0.25 mm (0.0098 in.) oversize gage:

88.25 mm [3.4744 in.]

0.50 mm [0.0197 in.] oversize gage:

88.50 mm [3.4843 in.]

Unit: mm [in.]

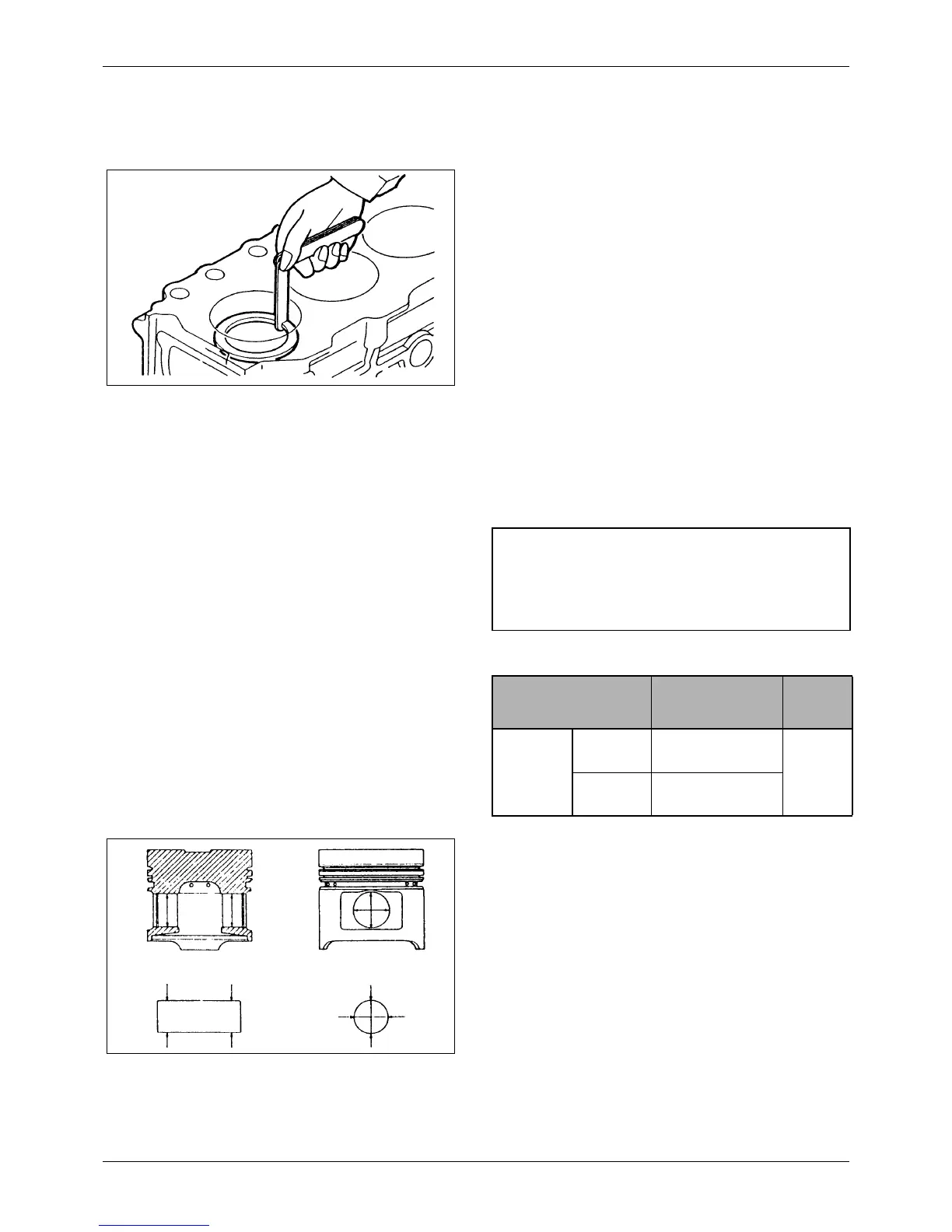

4. Checking clearance between piston pin and bore

Measure the inside diameter of the pin bore of the

piston and the diameter of the pin, as shown in the

illustration, to check the clearance. If the clearance

exceeds the service limit, replace the parts.

Figure 111 Checking clearance between ends of

piston ring

NOTE

Use a piston to place the piston ring in the liner by

pushing it squarely.

Item

Assembly

Standard

Service

Limit

Clearance

between

ends of

piston ring

No. 1, No.

2 ring

0.25 to 0.40

[0.00984 to 0.0157]

0.150

[0.0059]

Oil ring

0.30 to 0.50

[0.0118 to 0.0197]

+0.035

0

+0.0014

0

+0.035

0

+0.0014

0

+0.035

0

+0.0014

0

Figure 112 Measuring piston pin and bore

Measuring directionsMeasuring points

Loading...

Loading...