Instruction Manual #122162 25

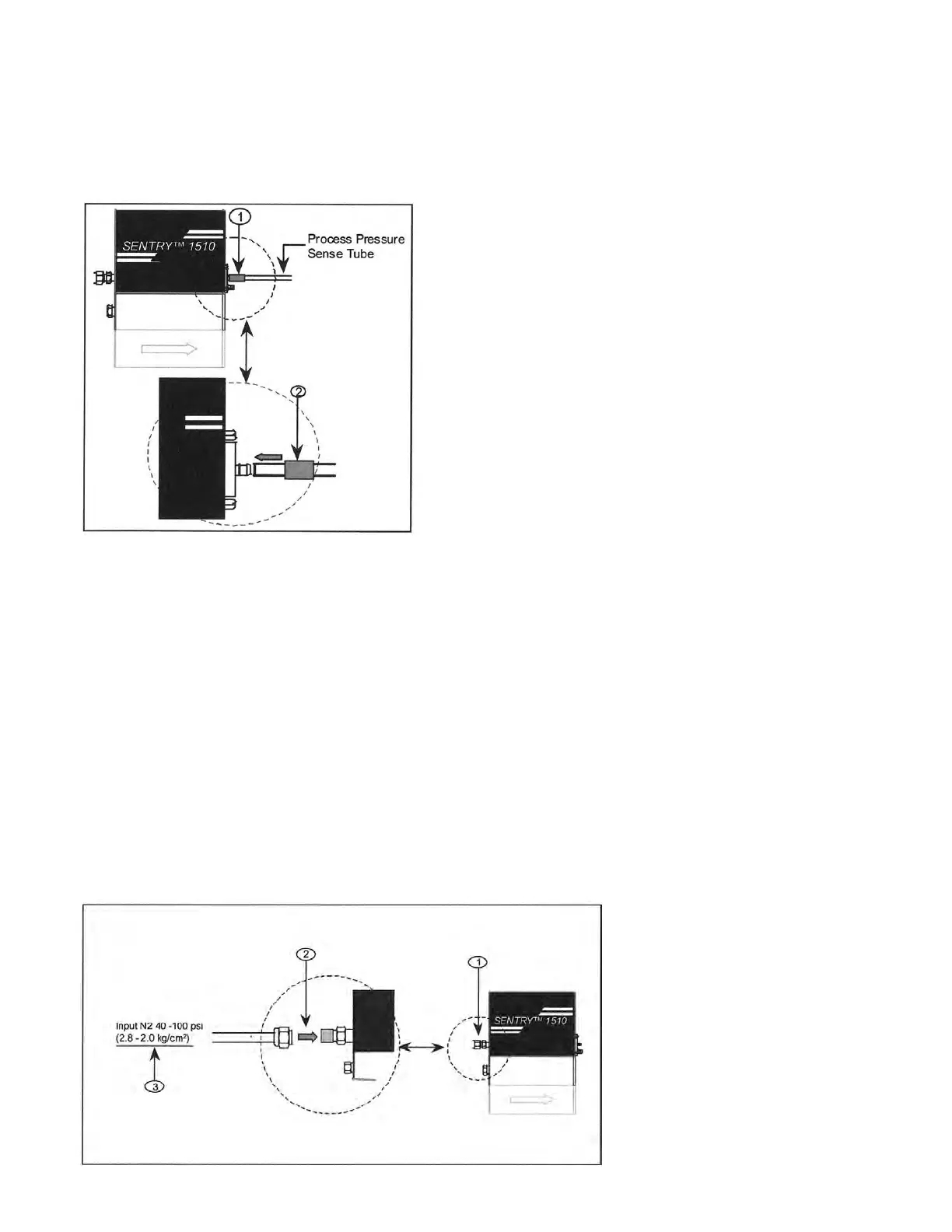

5.3.2 Connecting the Process Pressure Sense Tube to the SENTRY 1510

1. Connect the process pressure sense tube to the SENTRY 1510 by sliding the end of the tube

onto the barb fitting located next to the cable connector on the side of the SENTRY 1510.

2. Slide the teflon retainer over the barbed fitting to secure the tube. Loosely coil any extra sense

line and secure in a convenient location.

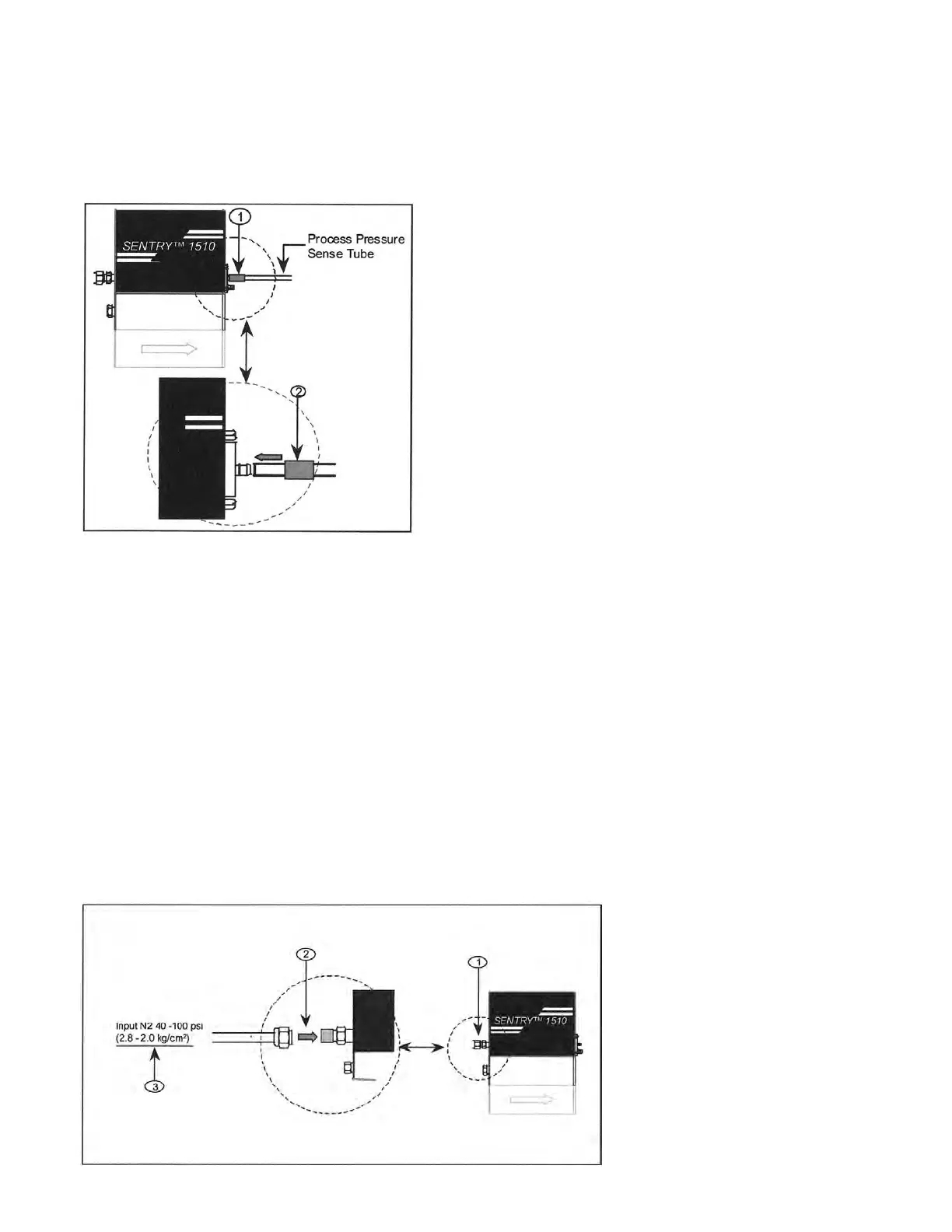

5.4 Nitrogen Supply to the SENTRY 1510

The SENTRY 1510 requires house grade nitrogen at a regulated pressure of 40-100 psi. (2.8 to 7.0

kg/cm2). It is recommended that a regulator and a pressure gauge be installed near the SENTRY

1510 Nitrogen connection. The SENTRY 1510 is equipped with two internal pressure regulators for

regulating and distributing the Nitrogen within the SENTRY 1510

5.4.1 Connecting the Nitrogen Supply Line to the SENTRY 1510

1. Connect the nitrogen supply line to the 1/4” Swagelok fitting located on the side of the SENTRY

1510 just above the input.

2. Finger tighten the Swagelok fitting, then use a wrench to tighten the nut 1 1/4 turns to engage

the internal compression fitting, forming a pressure tight fit.

3. Turn ON the N

2

supply and verify that the N

2

pressure at the SENTRY 1510 is 40-100 psi (2.8 to

7.0 kg/cm2)

Loading...

Loading...