Instruction Manual #122162 44

7. Maintenance & Troubleshooting

7.1 Maintenance

7.1.1 Scheduled Maintenance

There is no scheduled maintenance for either the SENTRY 1510 or the TIM 100/120. The

innovative and simple design of the SENTRY system allows for years of dependable,

maintenance-free service.

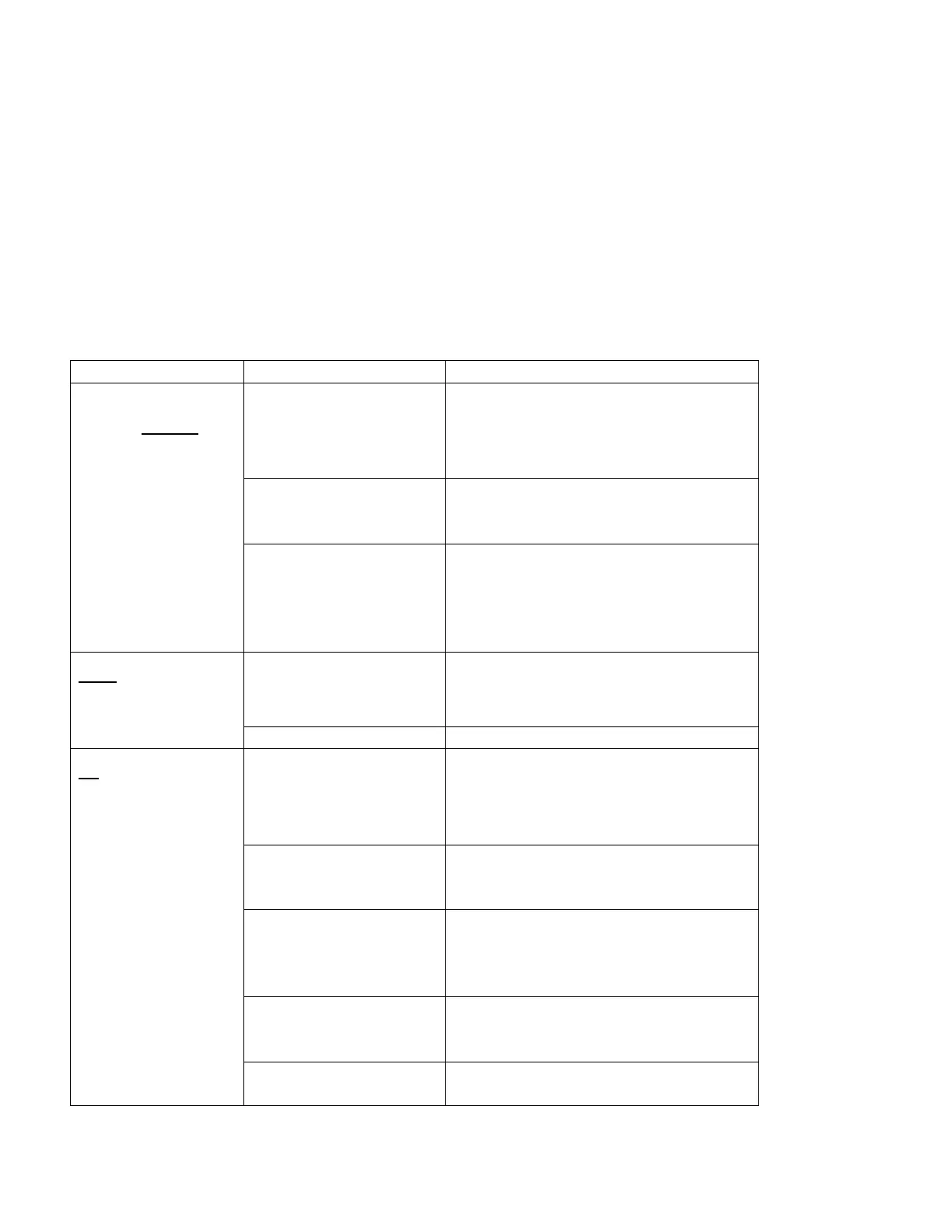

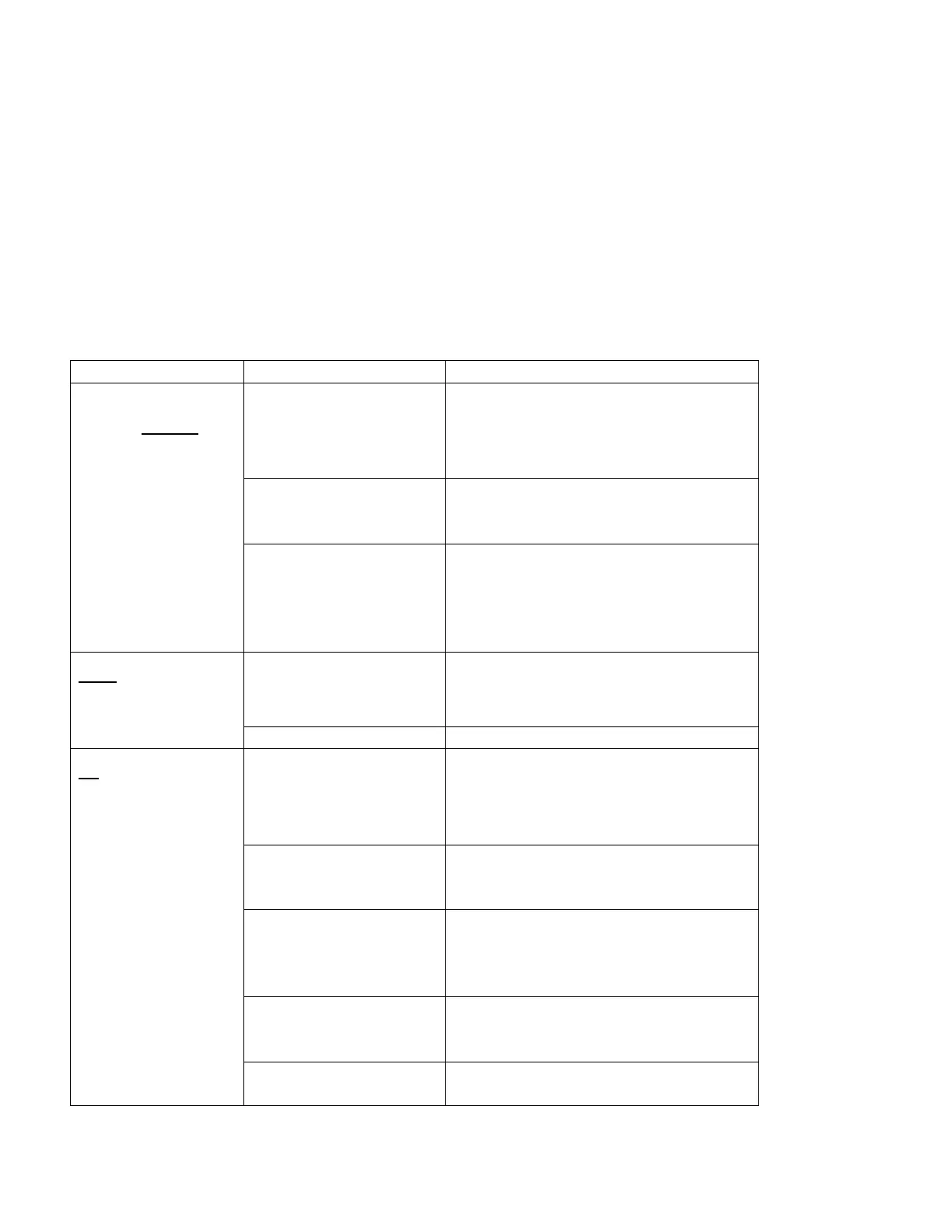

7.2 Troubleshooting

Many problems associated with the SENTRY 1510 or TIM 100/120 can be traced to improper

setup, installation or cabling. The following troubleshooting table and troubleshooting flow charts

will assist the user in identifying and correcting some of the most common problems. Reference

section numbers are included in the corrective action column.

Corrective Action (Section)

Set point read-

back is always

zero

(Tool Interfaced)

Analog ground and

power ground not

connected or common

Connect both analog ground and

power ground. Verify that they are

common on the tool. (5.7.2)

TIM 100/120

parameters incorrectly

configured

Ensure proper parameters are

selected for the model installed. (8)

Sense tube not

connected to process

exhaust or to

SENTRY 1510 sense

line port.

Connect the sense tube to the

process exhaust and to the

SENTRY 1510 sense line port.

(1)

High set point not

being achieved

(low set point ok)

Facility exhaust low or

dampers not fully

open

Open all dampers or increase

facility exhaust. (Error! Reference s

ource not found.)

All set points not

being achieved or

cannot change set

point

TIM 100/120

parameter “STPT

MODE” improperly set

for installation

Set TIM 100/120 parameter to

“Analog” for analog communication

or “Single” for stand-alone or serial

communication. (5.8.2)

(Analog Interface)

Analog interface

improperly installed

Properly install analog interface

cable. (5.7.2)

(Serial Interface)

Serial cable

improperly installed or

address not set

Properly install communication

cable. Adjust TIM 100/120 hex

code to match tool settings.

(5.7.3)

TIM 100/120

parameters incorrectly

configured

Ensure proper parameters are

selected for the model installed. (8)

Install with input and output

properly configured. (5.1)

Loading...

Loading...