12

EN

B CLASSIC / B FUTURA / S CLASSIC - TECHNICAL MANUAL

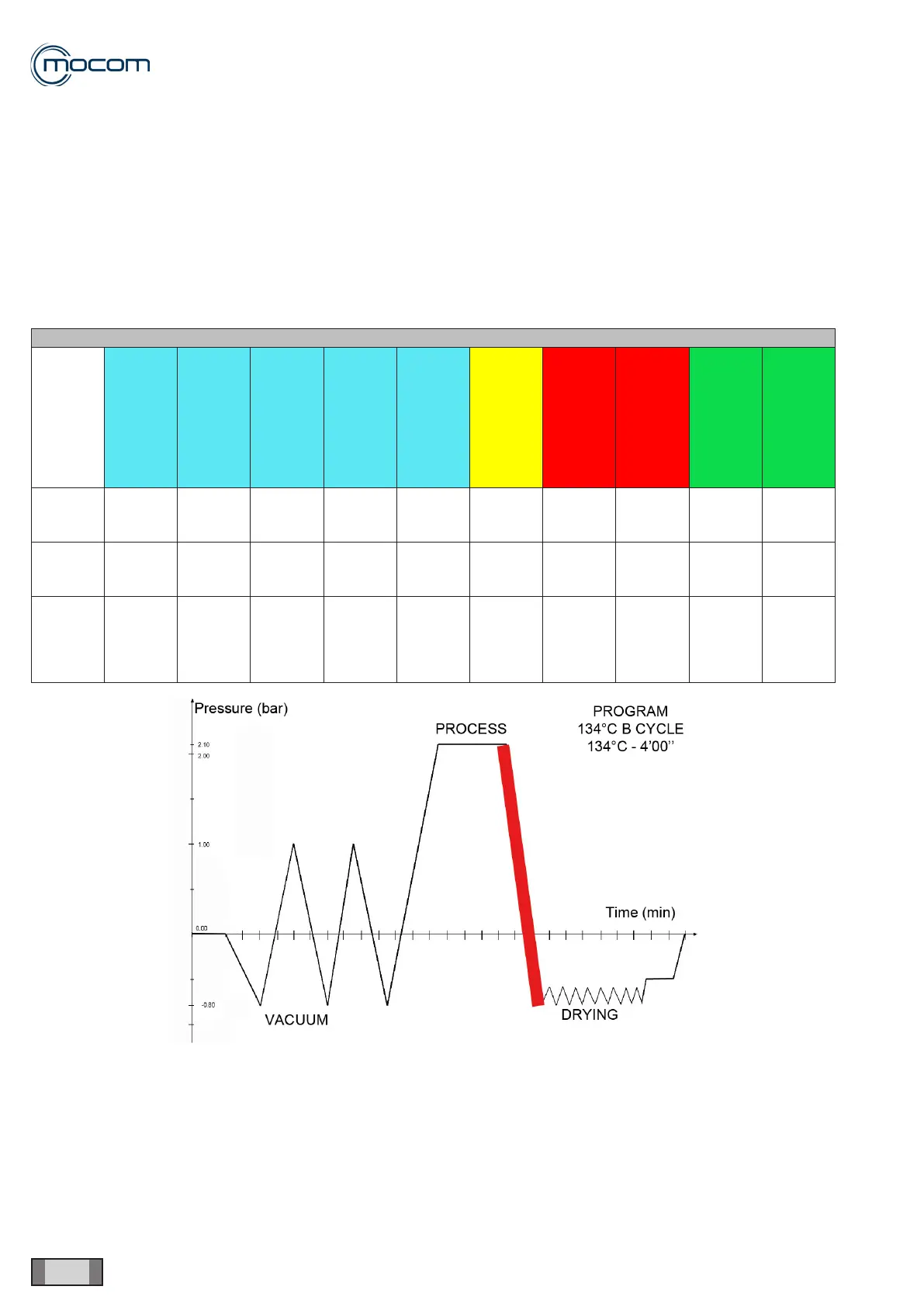

FUNCTIONING

1.9 DISCHARGE

When the PROCESS phase is completed, the DISCHARGE phase begins. During this phase, all steam is discharged

from the chamber and a vacuum value of - 0.80 bar is reached.

Just like the previous PRESSURE DROPS TO VACUUM phases, the DISCHARGE phase begins with a natural de-

pressurization phase that uses the pressure generated by steam, during which only the drain solenoid valves EV1 and

EV3 are operated.

To achieve complete DISCHARGE, until achieving – 0.80 bar, the system keeps lowering pressure by means of the

vacuum pump and operating the solenoid valve EV4.

Again, the solenoid valve EV2 is activated to balance pressure inside the hydraulic circuit and aid the operation of the

vacuum pump.

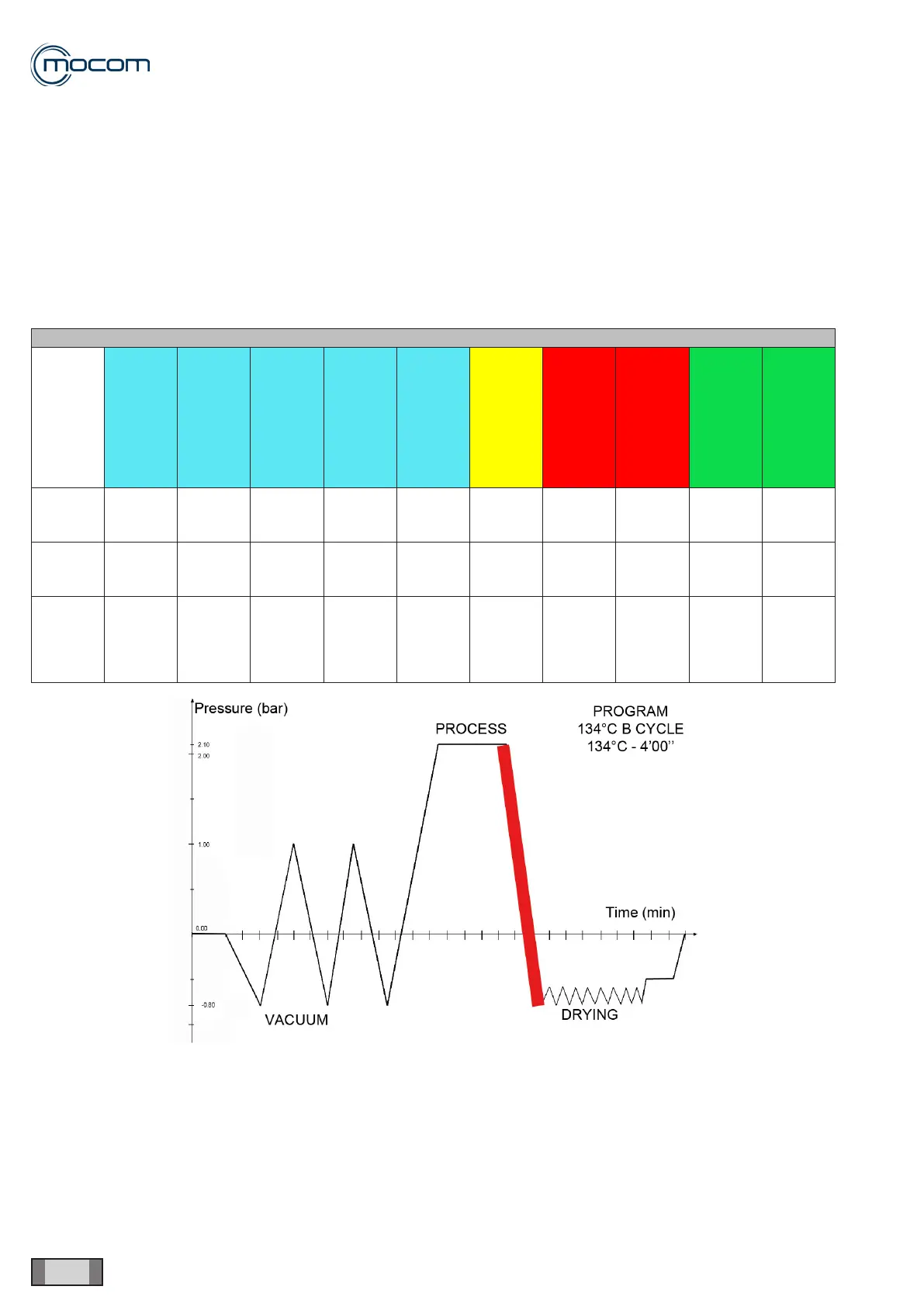

DISCHARGE - components on state

STATE

EV1

Drain

High (NO)

EV2

Air inlet

(NC)

EV3

Drain Low

(NC)

EV4

Drain

bypass

(3V)

EV5

Air inlet to

chamber

(NC)

FAN

WATER

PUMP

VACUUM

PUMP

CHAMBER

BUNDLE HTR

GENERATOR

HTNG ELMT

Direct

steam

discharge

Off

open

Off

closed

Off

closed

Off (2)

Off

closed

ON OFF ON ON ON

Direct

condensate

discharge

On

closed

Off

closed

On

open

Off (2)

Off

closed

ON OFF ON ON ON

Pressure

drops

from 0.10

to -0.80

bar

On

closed

Off

closed

On

open

On (1)

Off

closed

ON OFF ON ON ON

After the DISCHARGE phase, the DRYING phase begins. This phase is an integral part of the sterilization cycle.

Loading...

Loading...