13

EN

TECHNICAL MANUAL - B CLASSIC / B FUTURA / S CLASSIC

FUNCTIONING

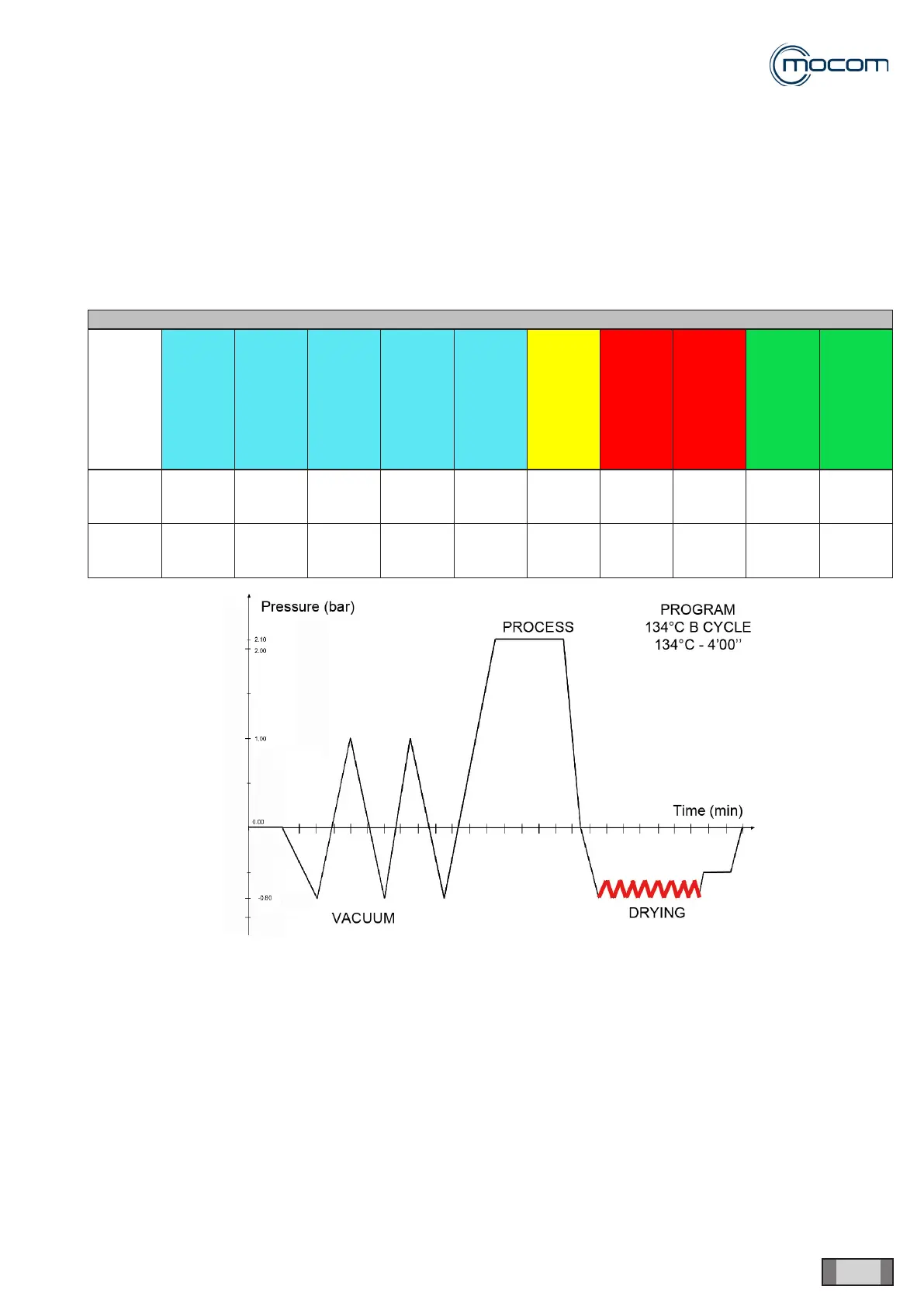

1.10 DRYING

This phase of the sterilization cycle eliminates any moisture left inside the chamber and fully dries the load.

Drying is achieved by maintaining a negative pressure level inside the chamber, so that condensate can evaporate

even at temperatures below 100°C.

The drying phase has a different duration for each sterilization cycle (e.g. 12’ for 134°C universal cycle). During the dry-

ing phase, a series of pressure pulses take place in the chamber, approximately between - 0.80 bar and - 0.40 bar, to

aid total removal of any residual steam; the number of pulses may vary depending on the moisture content in the load.

During the pressure rise phases that take place during these pulses, solenoid valve EV5 is activated to let air ow into

the chamber through the bacteriological lter; this air ow aids steam removal.

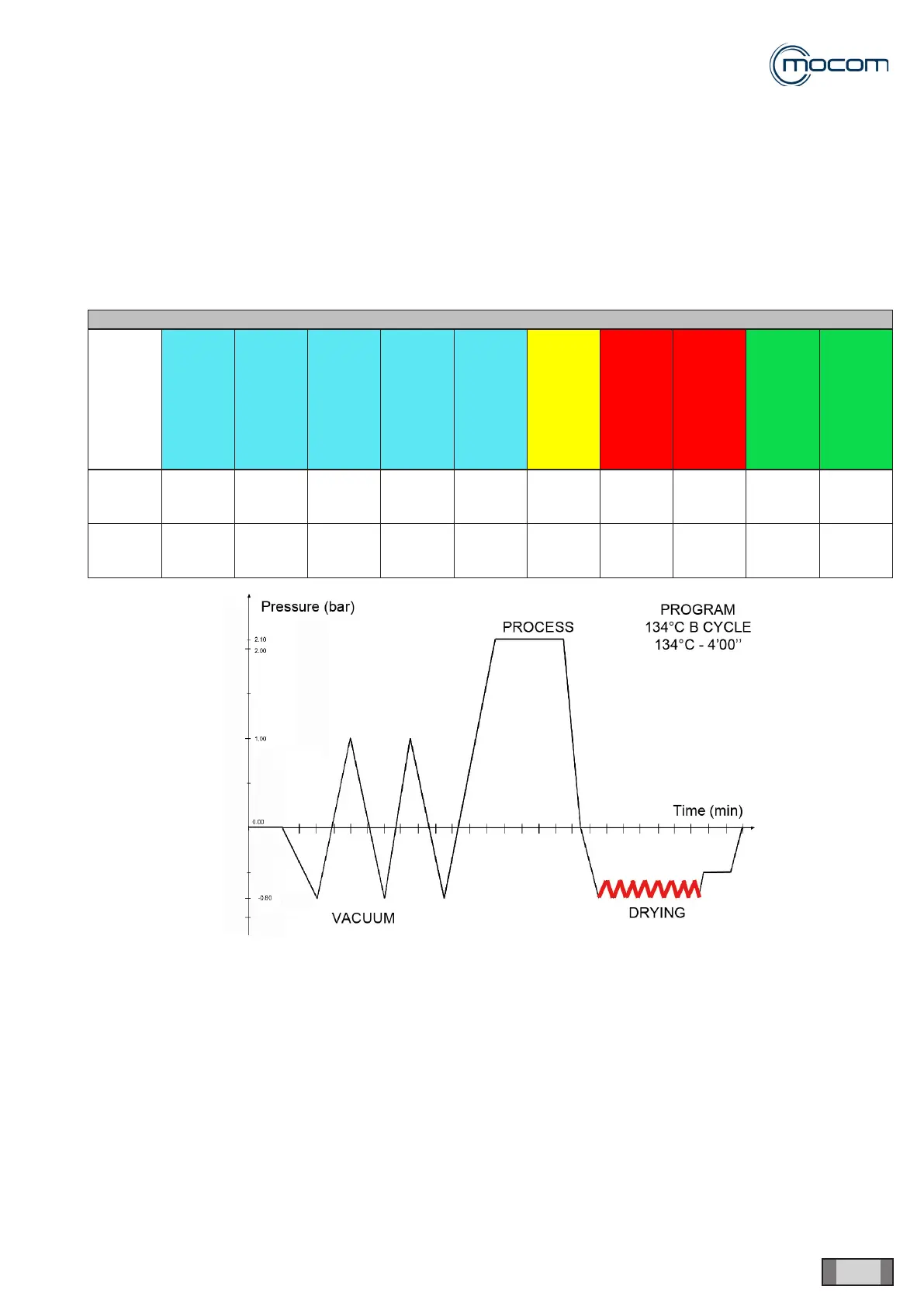

DRYING - components on state

STATE

EV1

Drain

High (NO)

EV2

Air inlet

(NC)

EV3

Drain Low

(NC)

EV4

Drain

bypass

(3V)

EV5

Air inlet to

chamber

(NC)

FAN

WATER

PUMP

VACUUM

PUMP

CHAMBER

BUNDLE HTR

GENERATOR

HTNG ELMT

Pressure

drop

On

closed

Off

closed

On

open

On (1)

Off

closed

ON OFF ON ON ON

Pressure

rise

On

closed

Off

closed

On

open

On (1)

On

open

ON OFF ON ON ON

When the standard drying time – plus any additional drying time set by user –have elapsed, the VENTILATION phase

begins.

Loading...

Loading...