5

EN

TECHNICAL MANUAL - B CLASSIC / B FUTURA / S CLASSIC

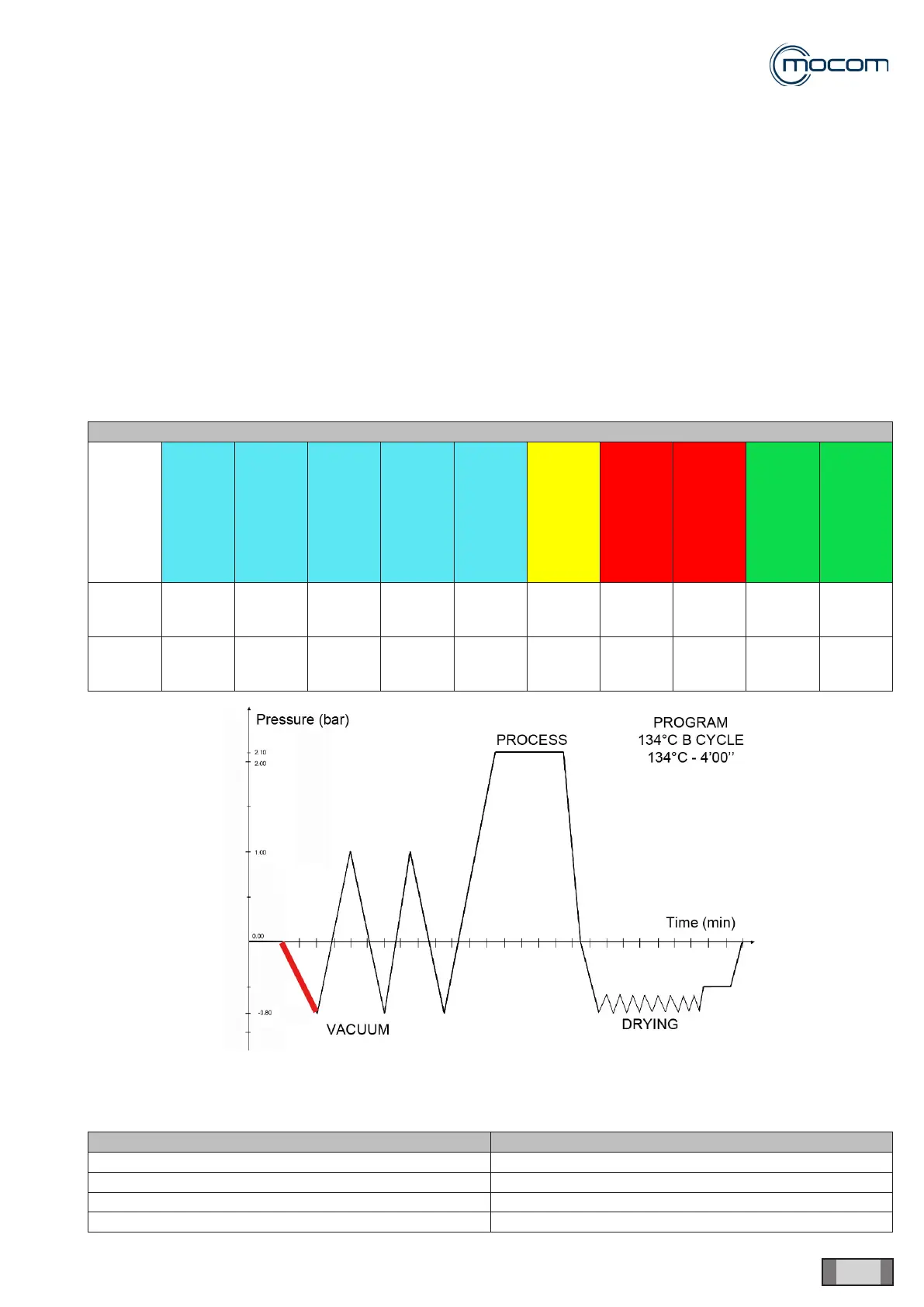

FUNCTIONING

1.3 1st VACUUM PHASE

This phase marks the beginning of the sterilization cycle proper. As the vacuum pump is activated, the maximum

vacuum level in the chamber, namely – 0.80 bar, can be reached (S 17 Classic -0.75 bar).

The tube bundle heating element of the chamber and the generator heating element remain activated throughout this

phase so the steam generation can be managed properly.

The 1

st

VACUUM PHASE must ensure that as much air as possible is removed from the chamber. In order to achieve

this, repeated steam shots are injected as pressure drops to aid removal of any remaining air.

These steam shots are operated automatically according to pressure value in the chamber as follows:

- steam shot starts > chamber pressure reading – 0.70

- steam shot ends > chamber pressure reading – 0.60

This sequence is repeated 3 times, and pressure drops until reaching the preset vacuum level of – 0.80 bar. This value

triggers the next phase, namely the 1

st

PRESSURE RISE.

The control system operates the solenoid valve EV2 (air inlet) when it is needed to improve vacuum pump perfor-

mance, which may be the case during the last pressure drop phase.

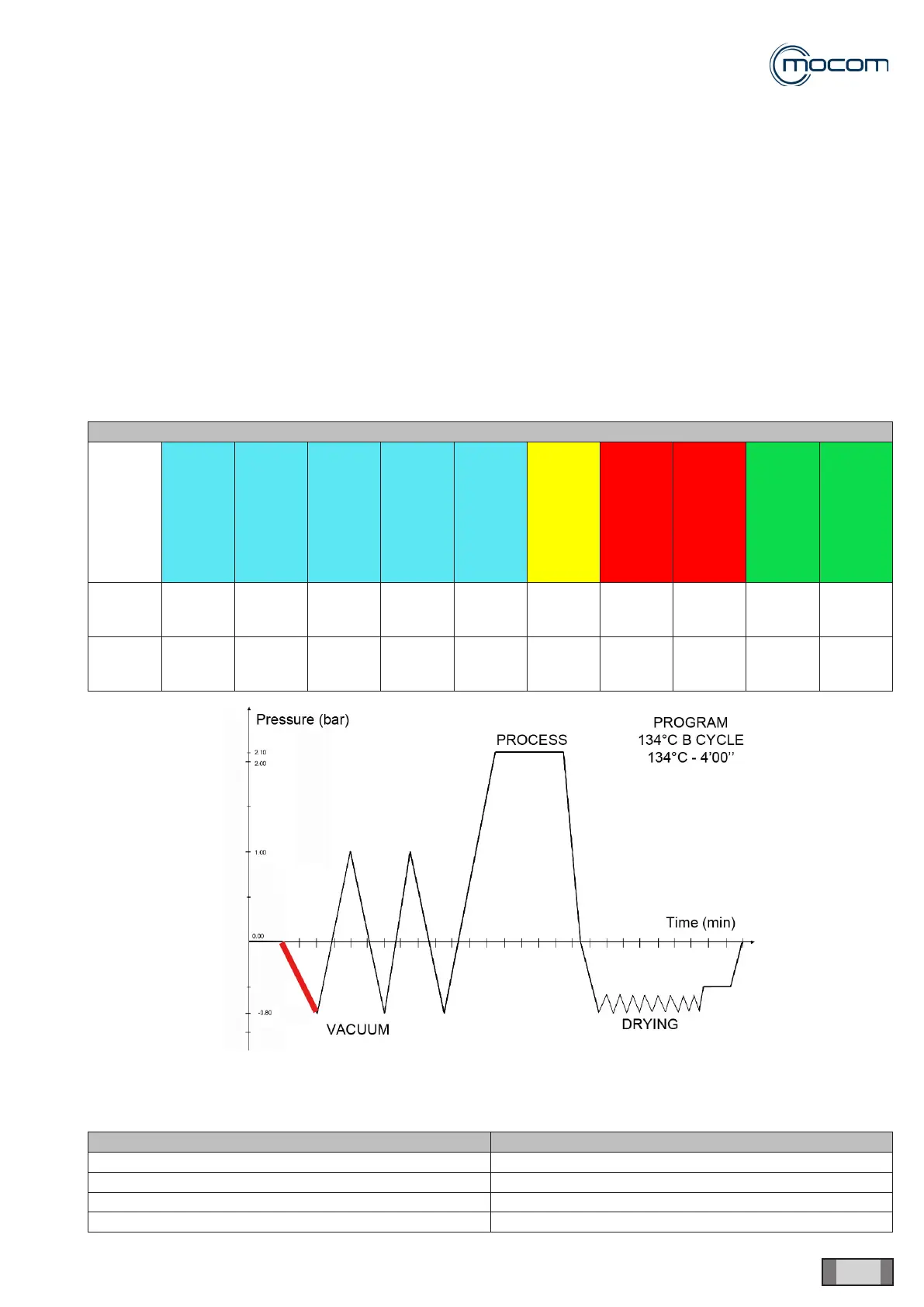

1

st

VACUUM PHASE - components on state

STATE

EV1

Drain

High (NO)

EV2

Air inlet

(NC)

EV3

Drain Low

(NC)

EV4

Drain

bypass

(3V)

EV5

Air inlet to

chamber

(NC)

FAN

WATER

PUMP

VACUUM

PUMP

CHAMBER

BUNDLE HTR

GENERATOR

HTNG ELMT

Drop

to

vacuum

On

closed

Off

closed

On

open

On (1)

Off

closed

ON OFF ON ON ON

Steam

shot

Off

open

Off

closed

Off

closed

On (1)

Off

closed

ON ON ON ON ON

A preset minimum pressure value can be reached during the vacuum pulses; this value varies with each vacuum pump

type installed on the autoclaves.

VACUUM PUMP PMIN [bar]

Type H5 -0.75

Type H5P3 -0.80

Type EVO10 -0.80

Type EVO30 -0.80

Loading...

Loading...