24

EN

B CLASSIC / B FUTURA / S CLASSIC - TECHNICAL MANUAL

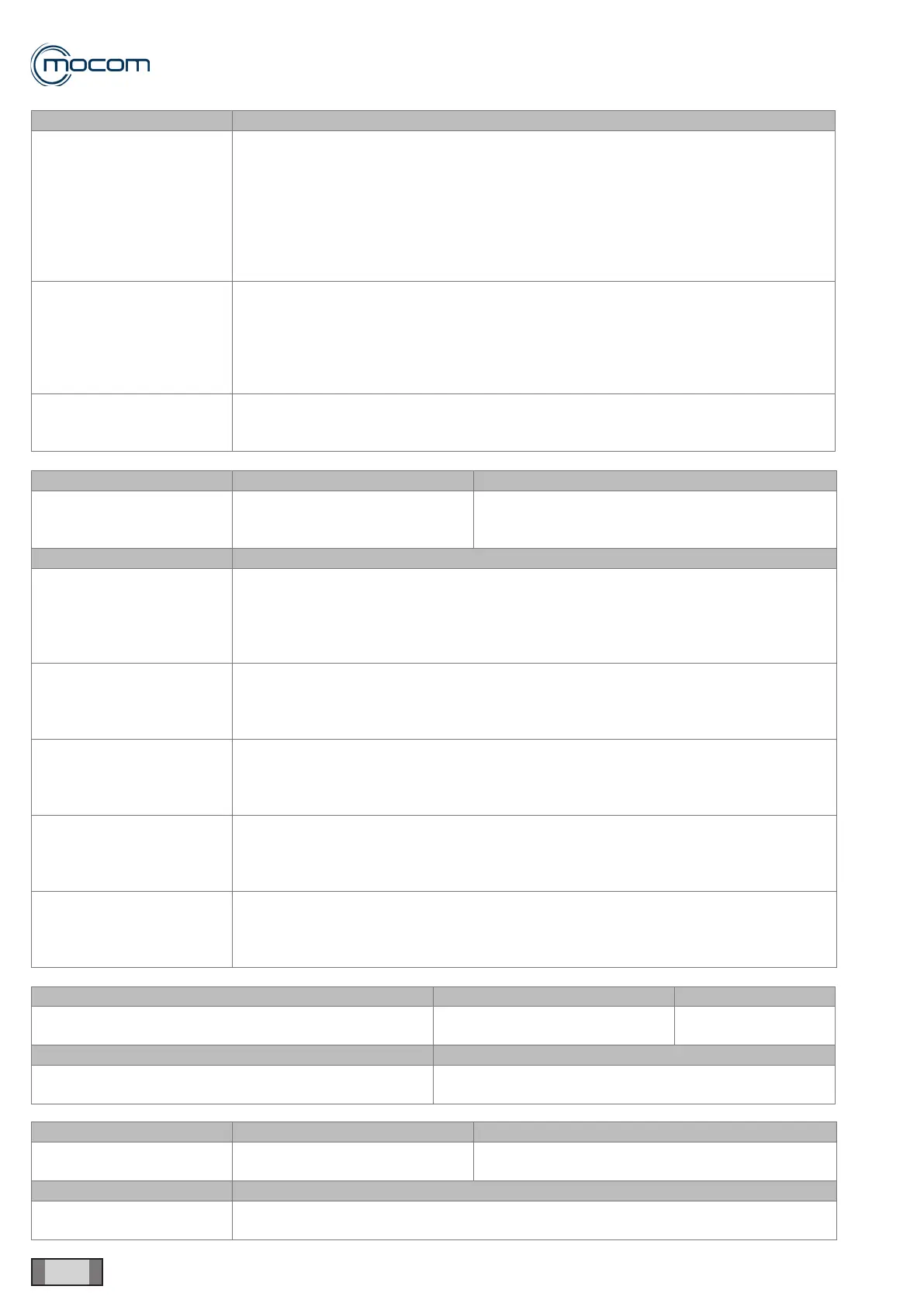

ALARMS

Possible causes / Checks Solution

Problem with Teon tube

sealing - check tubes and

connections.

For Teon tubes connected to pressure transducer and safety pressure switch, check:

- Proper fastening of tubes to ttings at chamber rear end and to the 2 components.

- Condition of Teon tube on tting, under locking ring nut.

Tighten properly, if needed, after cutting off the end of the Teon tube that was locked

under the ring nut.

To check for proper sealing, you may start a test cycle from menu SERVICE/TEST

CYCLES/NO VACUUM SQ, that will pressurize the system omitting the pre-vacuum

phases.

Problem with Manifold

solenoid valve sealing -

check for proper sealing.

For solenoid valves EV1 – EV3 – EV5, check:

- cursor and seat for proper closing, condition and cleanliness.

To check for proper sealing, it might be a good idea to test the individual solenoid

valves from menu SERVICE/COMPONENT TEST/SOLENOID VALVES – OTHER

COMPONENTS SQ 12/SQ 13, that lets you actuate the individual solenoid valves to

conrm that they close properly.

Problem with steam

generator sealing – check

for proper sealing.

Check the condition of the reinforced tubes connected to the generator and their

stainless steel clamps.

Check for proper sealing at the coupling between outer body/inner core of generator.

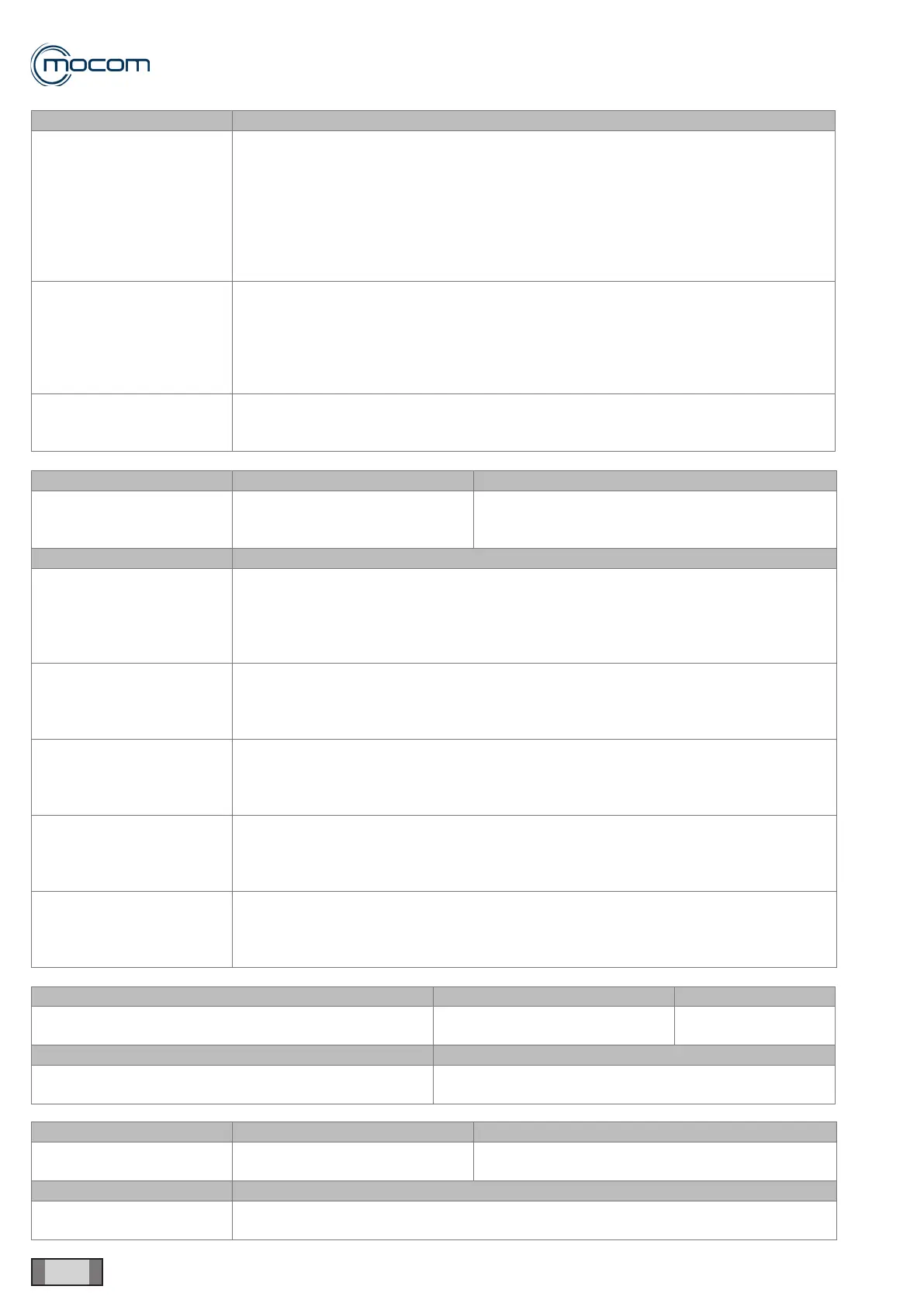

LCD E 902 Indication Alarm description Effect / Symptom

TEST FAILED

VACUUM PULSE FAILED:

Vacuum test failed, vacuum pulse

TIMEOUT exceeded.

Negative pressure value of – 0.80 bar not reached

before set TIMEOUT.

Possible causes / Checks Solution

Problem with vacuum pump

start-up – check pump.

Conrm pump start-up when test cycle is activated.

To perform this check, it might be a good idea to activate the vacuum pump from menu

SERVICE/COMPONENT TEST/OTHER COMPONENTS – SOLENOID VALVES SQ

14, that lets you detect air suction from the chamber.

Check/Change the vacuum pump.

Problem with vacuum pump

efciency – check pump.

Check chamber drain lter.

Check vacuum pump diaphragms.

Check vacuum pump shutters.

Vacuum pump maintenance.

Problem with solenoid valve

activation – check solenoid

valves.

Check for proper activation and opening of EV3 – EV4.

To perform this check, it might be a good idea to check for EV3 –EV4 opening activate

from menu SERVICE/COMPONENT TEST/OTHER COMPONENTS – SOLENOID

VALVES SQ 15, that lets you detect air suction from the chamber.

Problem with tubes – check

tubes.

Check condition and proper connection of:

Reinforced tubes of chamber

TEFLON tubes

Braided tubes of heat exchanger

Problem with heat

exchanger sealing - check

heat exchanger.

Disconnect inlet and outlet tubes of exchanger, connect tubes together so as to bypass

exchanger.

Activate test cycle.

Change heat exchanger.

LCD E 998 Indication Alarm description Effect / Symptom

REMOTE SERVICE Remote access in Service mode

Possible causes / Checks Solution

A connection to “Service” menu occurred from remote

through Ethernet or WiFi (Futura only)

Nothing to do

LCD E 999 Indication Alarm description Effect / Symptom

MANUAL INTERRUPTION Manually interrupting the cycle.

STOP control is kept depressed for at least 3” and

cycle is stopped.

Possible causes / Checks Solution

User pressed the START/

STOP key.

The manual STOP control must only be used when necessary.

Do not use it to add load to the chamber.

Loading...

Loading...