33

EN

TECHNICAL MANUAL - B CLASSIC / B FUTURA / S CLASSIC

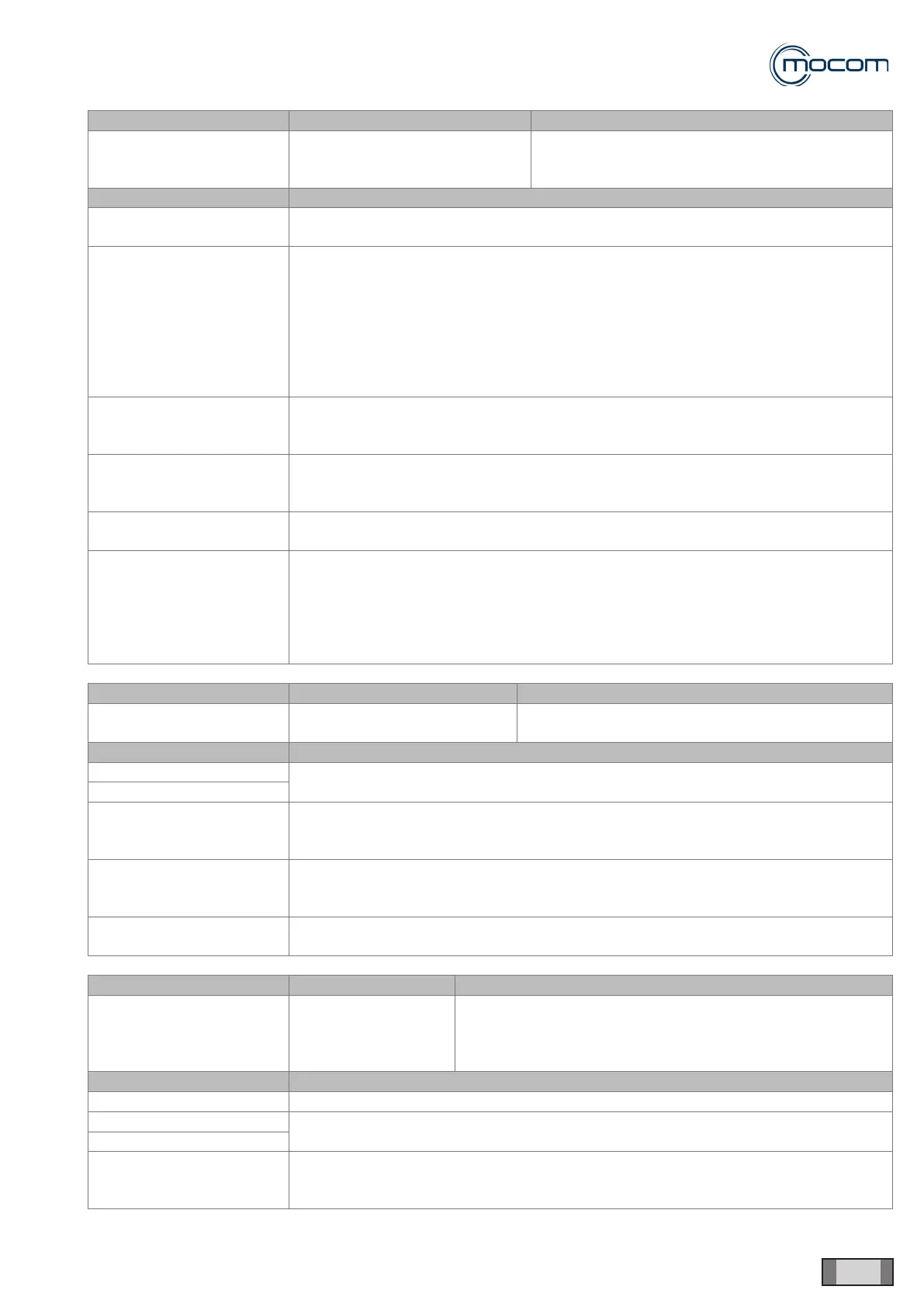

ALARMS

LCD A 258 Indication Alarm description Effect / Symptom

PPP TIMEOUT

Third pressure pulse from 0.00

to process start not completed

within timeout.

Third pressure rise from 0.00 to specic pressure

value for selected cycle (1.10 bar / 2.15 bar) not

completed within timeout.

Possible causes / Checks Solution

Problem with autoclave

loading – check load.

Check quantity and arrangement of load inside chamber.

Observe the indications provided in the User Manual.

Problem with water

injection pump of steam

generator – check device.

Problem with steam

generator clogging – check

device.

Check feed tank lter and water injection pump inlet lter.

Check for proper activation of water pump and check that EV6 opens.

To perform this check, it might be a good idea to activate vacuum pump and EV6 from

menu SERVICE/COMPONENT TEST/OTHER COMPONENTS – SQ 17, that lets you

detect water owing through the generator and into the chamber.

Identify leaks on tubes connecting water pump and generator.

Change vibration pump.

Steam generator maintenance – see datasheet ST01.

Problem with steam

generator warm-up – check

device.

Check and reset safety thermostat if needed.

Check steam generator heating element.

See ST01 – steam generator datasheet.

Problem with manifold

solenoid valve sealing –

check components.

Check EV1 for proper power supply and sealing.

Check EV3 for proper sealing.

MANIFOLD - see datasheet ST02.

Steam seepage through

door gasket.

Clean door gasket and steel ledge thoroughly.

Change door gasket.

Problem with door sealing –

check closing system.

Check for steam leaks through door.

Check condition and position of door gasket.

Check for proper operation of door closing and locking system.

To perform this check, it might be a good idea to activate the closing system from menu

SERVICE/COMPONENT TEST/DOOR – SQ 20, measuring the current demand from

the locking servomotor.

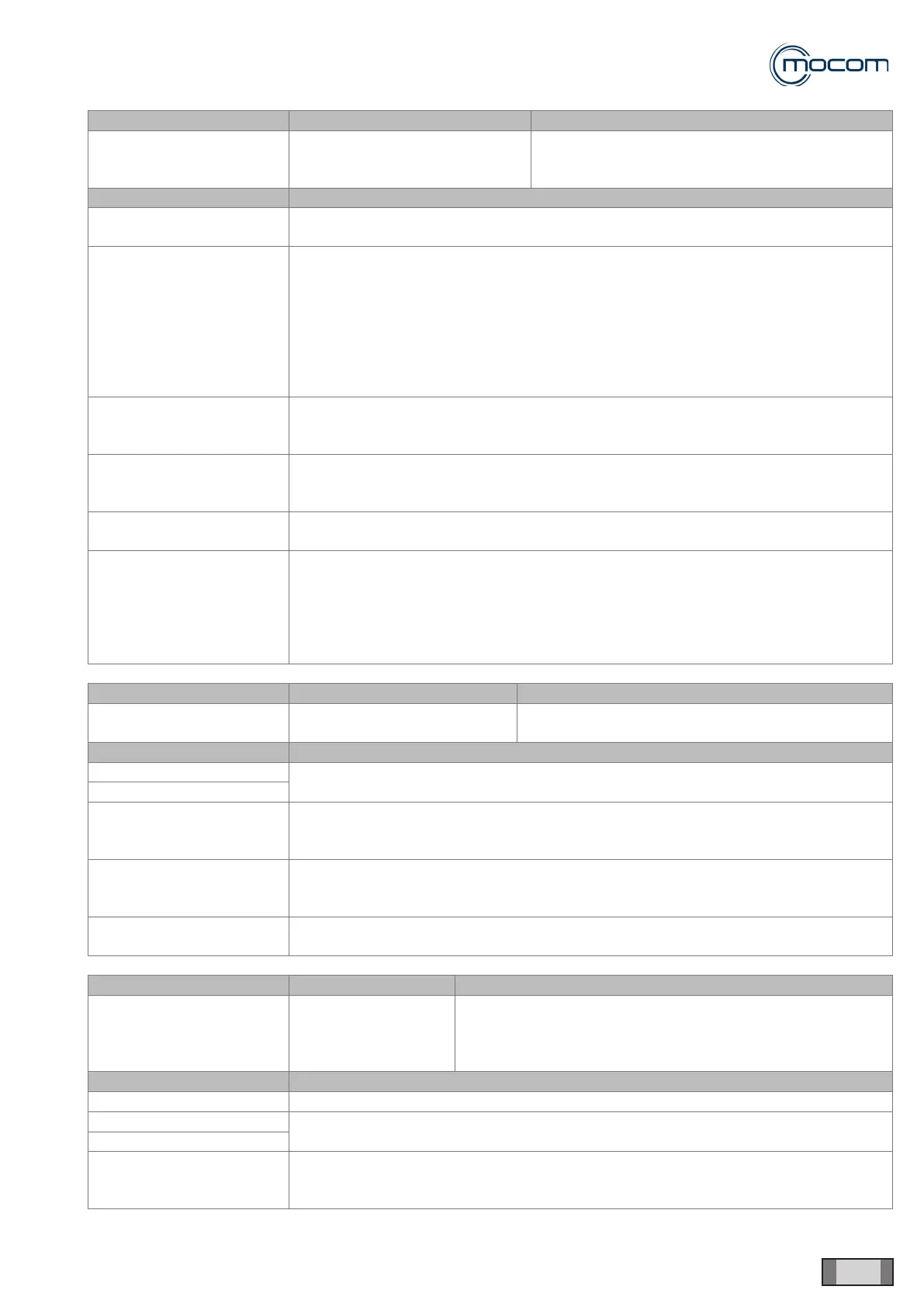

LCD A 260 Indication Alarm description Effect / Symptom

PPD TIMEOUT

Chamber depressurization not

completed within timeout.

Problem with solenoid valves opening changeover

during steam discharge.

Possible causes / Checks Solution

EV3 shaft will not slide.

Clean and/or replace cursor and cursor holder of EV3 – see technical datasheet

ST02 - MANIFOLD.

EV3 dirty.

EV3 not powered on.

Check EV3 wiring.

Check EV3 supply.

To perform this check, activate the EV3 from menu SERVICE - SQ 15.

Check position of autoclave

feet.

If any feet have been removed, ret them.

Instruct operators.

Adjust feet to achieve proper autoclave inclination.

Check chamber lter

Clean chamber lter.

Change chamber lter.

LCD A 360 Indication Alarm description Effect / Symptom

PPD TIMEOUT

Chamber

depressurization not

completed within

timeout.

Problem with solenoid valves opening changeover during

steam discharge.

Possible causes / Checks Solution

EV3 interrupted. Change cursor and cursor holder of EV3.

EV3 shaft will not slide.

Clean and/or replace cursor and cursor holder of EV3.

EV3 dirty.

EV3 not powered on.

Change manifold wiring.

Change fuse.

Change card.

Loading...

Loading...