MONITOR HEATING SYSTEM

Section

4:

Maintenance/Servicing

4-1

CLEANING

THE

CABINET

When

the

cabinet

is

soiled, wipe

it

with

a

damp

cloth. Restore

the

shine with

a dry

cloth.

The use

of

abrasive household cleaners

may

dull

the

finish.

4-2

CHECKING

THE

FLUE

PIPE

At

the

beginning

of

each heating season, check

the

inside

of the

flue

pipe.

Foreign matter, spider

webs,

etc. must

be

removed.

Be

sure

all

fittings

and

joints

are

tight.

NOTE:

Make sure that

all

exhaust pipe

and

intake

pipe connections

are

firmly mated.

Make

sure that

the

connections between

the

flue pipe

and

exhaust/air intake pipe

and

hose

are

secured

by the

pipe holder

(P/N

4006)

and the

hose band (P/N 4008).

4-3

CLEANING

THE

INTERIOR

Remove

the

front cover

and

louver,

and

vacuum

and

wipe away dust

and

other accumulation.

4-4

CLEANING

THE

BLOWER

GUARD

Heating efficiency will

be

reduced

if the

blower

guard

at

rear

of the

cabinet

is

blocked with

dirt

or

dust.

Blockage also produces

a

rise

in

heat that

could

cause

the

heater

to

shut

off.

Wipe

the

guard clean

at

least once

a

week.

4-5

ELECTRIC

MOTOR

MAINTENANCE

Motors

are

permanently

lubricated

and

need

no

lubrication.

Keep

fan and

motor free

of

dust

and

dirt

by

cleaning annually.

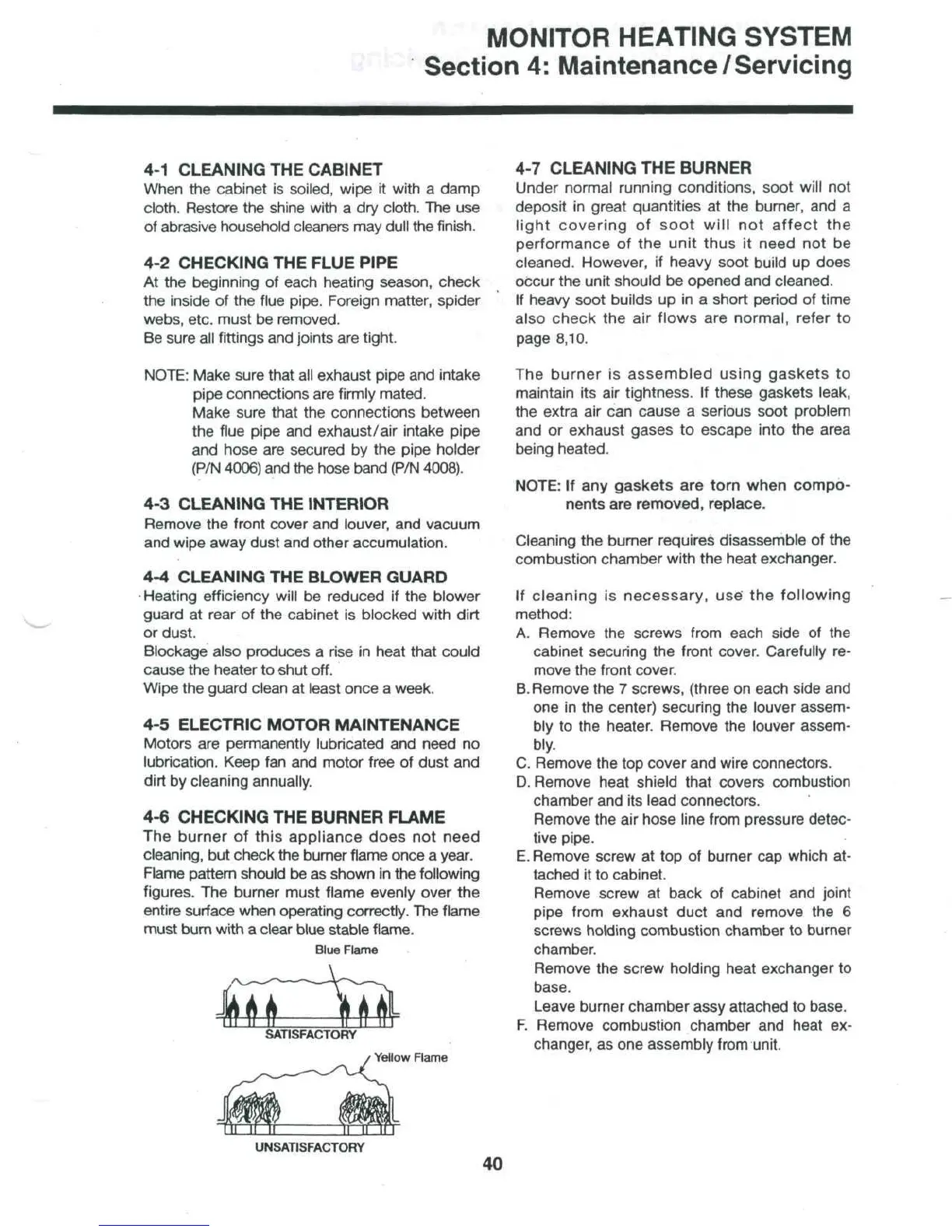

4-6

CHECKING

THE

BURNER

FLAME

The

burner

of

this

appliance

does

not

need

cleaning,

but

check

the

burner flame once

a

year.

Flame pattern

should

be as

shown

in the

following

figures.

The

burner must flame evenly over

the

entire surface when operating

correctly.

The

flame

must

bum

with

a

clear

blue

stable

flame.

Blue

Flame

Yellow

Flame

4-7

CLEANING

THE

BURNER

Under normal running

conditions,

soot will

not

deposit

in

great quantities

at the

burner,

and a

light

covering

of

soot

will

not

affect

the

performance

of the

unit

thus

it

need

not be

cleaned. However,

if

heavy soot build

up

does

occur

the

unit

should

be

opened

and

cleaned.

If

heavy soot

builds

up in a

short period

of

time

also check

the air

flows

are

normal, refer

to

page 8,10.

The

burner

is

assembled

using

gaskets

to

maintain

its air

tightness.

If

these gaskets leak,

the

extra

air can

cause

a

serious soot problem

and or

exhaust gases

to

escape into

the

area

being heated.

NOTE:

If any

gaskets

are

torn

when

compo-

nents

are

removed,

replace.

Cleaning

the

burner requires disassemble

of the

combustion chamber with

the

heat exchanger.

If

cleaning

is

necessary,

use

the

following

method:

A.

Remove

the

screws from each side

of the

cabinet

securing

the

front

cover. Carefully

re-

move

the

front cover.

B.

Remove

the 7

screws, (three

on

each side

and

one

in the

center) securing

the

louver assem-

bly to the

heater. Remove

the

louver assem-

bly.

C.

Remove

the top

cover

and

wire connectors.

D.

Remove heat shield that covers combustion

chamber

and its

lead connectors.

Remove

the air

hose line from pressure detec-

tive pipe.

E.

Remove

screw

at top of

burner

cap

which

at-

tached

it to

cabinet.

Remove

screw

at

back

of

cabinet

and

joint

pipe

from

exhaust duct

and

remove

the 6

screws

holding

combustion

chamber

to

burner

chamber.

Remove

the

screw holding heat exchanger

to

base.

Leave

burner chamber assy attached

to

base.

F.

Remove combustion chamber

and

heat

ex-

changer,

as one

assembly

from

unit.

UNSATISFACTORY

40

Loading...

Loading...