SECTION SIX – COMMANDS

DS2000 USER’S MANUAL (rev.C)

6.7

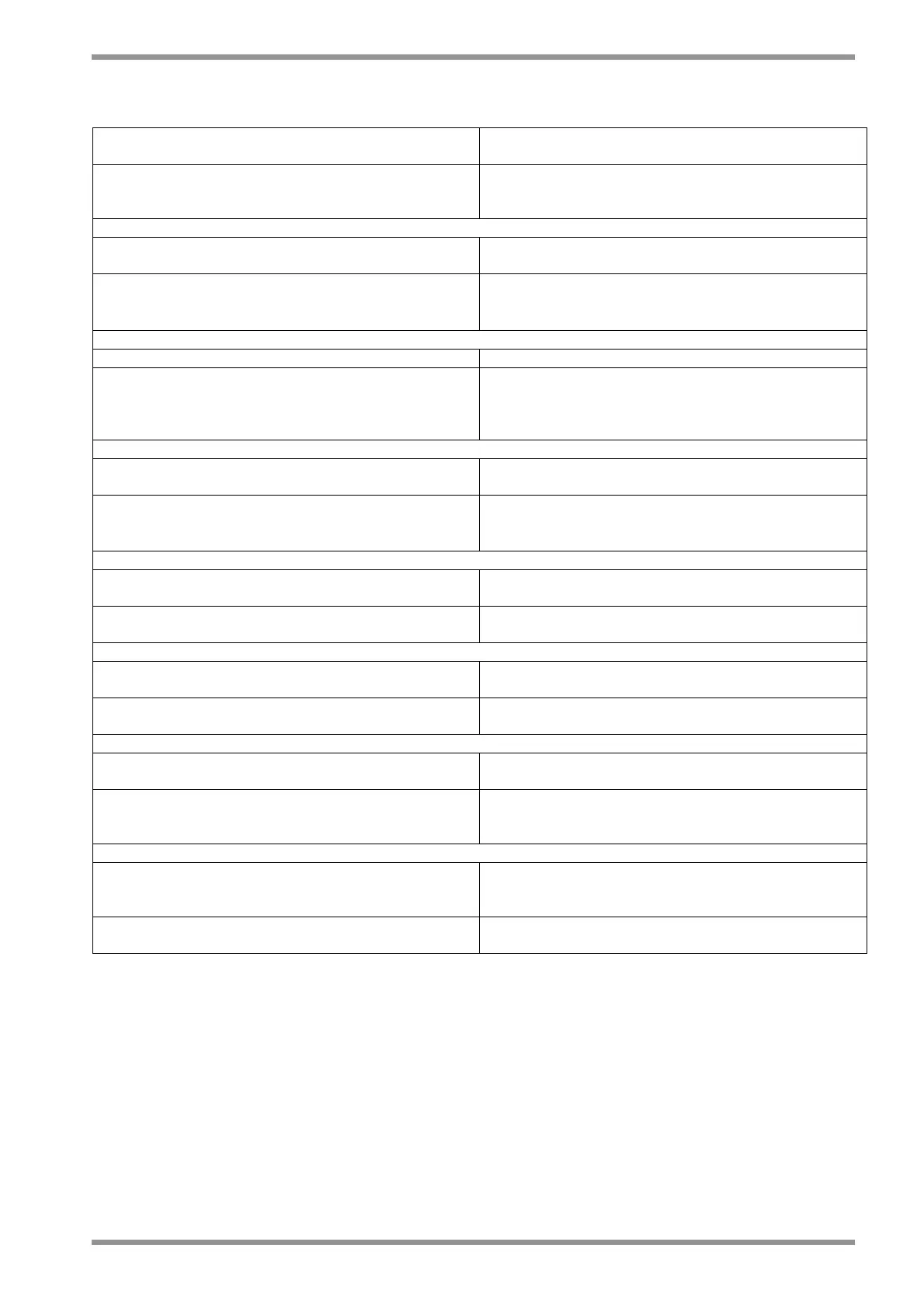

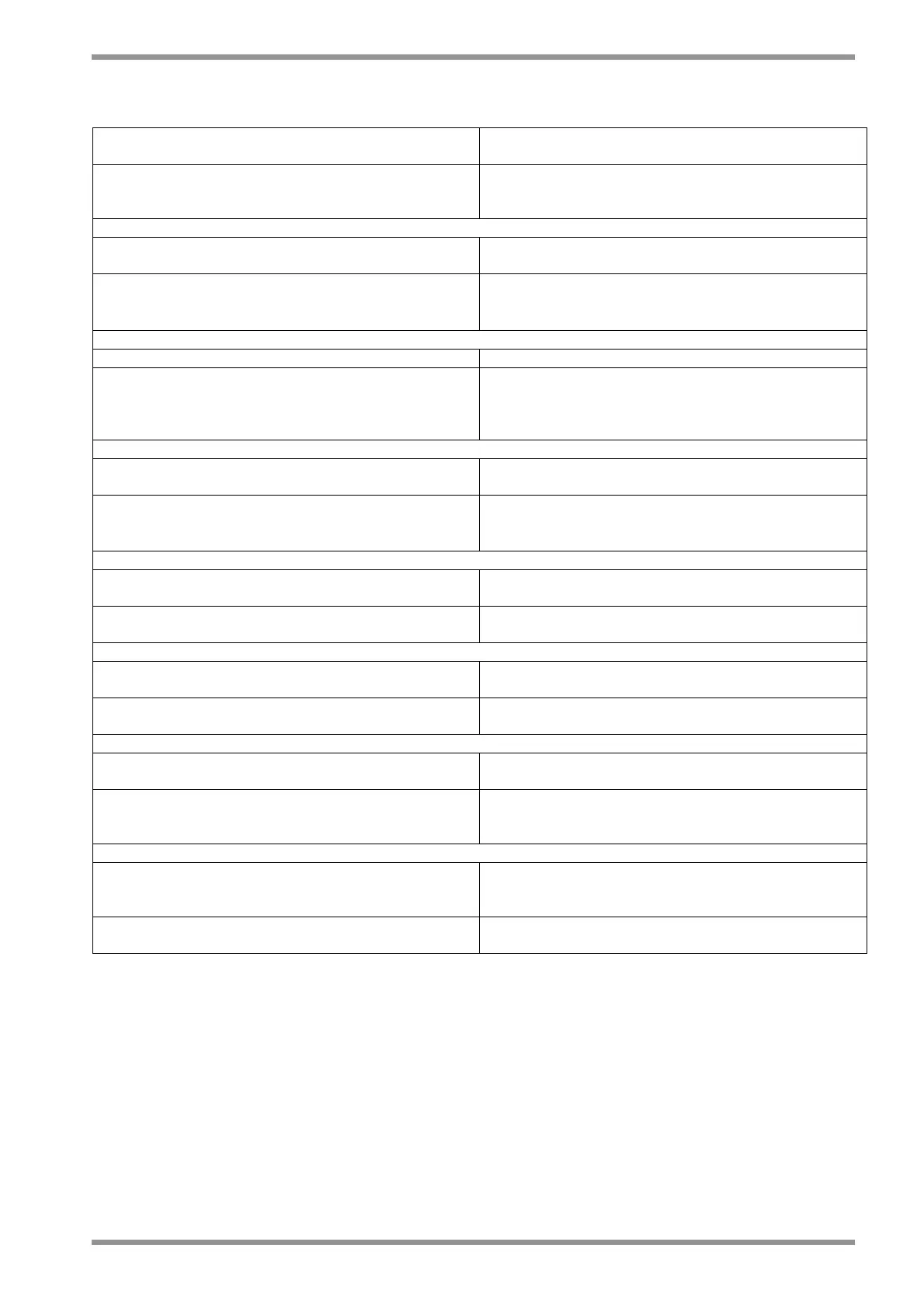

6.3.1 DRIVE PARAMETERS MENU DESCRIPTION

DRIVE ADDRESS DRVADDR=

Description: it indicates drive address for serial

communication

Allowed values:

from 1 to 63

Note: set a progressive and different value per each

drive to obtain only one serial line to interrogate all

the drives existing in the machine

PTCNTC THRESHOLD=

Description: it indicates NTC/PTC threshold value

used to protect motor from overtemperature

Allowed values:

from 100 Ω to 10000 Ω in 1 unit steps

Note: set following value for Moog motor:

• 1200 Ω for PTC thermal feedback

• 6500 Ω for NTC thermal feedback

RECOVERY RESIST. RESREC=

Description: it indicates the recovery resistor value

Allowed values:

from 3 Ω to 100 Ω in 1 unit steps

Note: set the value indicated on the drive label. If the

precise value is not available, set the higher one. If

the value is too high the drive will not be able to

dissipate the recovered energy

RR PROTECTION

Description: protection against recovery resistor

thermal overload

Allowed values:

• 0 (for protection disabled)

• 1 (for protection enabled)

Note: see section 7 for additional details on this

function setup

RECOVERY RESIST. POWER=

Description: nominal resistor power, used for

resistor thermal protection

Allowed values:

from 10 W to 6400 W in 1 unit steps

Note: see section 7 for additional details on this

function setup

RECOVERY RESIST. COEFF.=

Description: special parameter, used for resistor

thermal protection

Allowed values:

from 1 to 32000 in 1 unit steps

Note: see section 7 for additional details on this

function setup

TACHO SCALE=

Description: it indicates the max tacho signal value

obtained at max number of motor revolutions

Allowed values:

from 5 V to 10 V in 100 mV unit steps

Note: setting 10 V for the max speed value allows to

obtain a simple and direct ratio between read value

and speed

ANAL.REF. ZERO BAND=

Description: set a dead band on the speed/torque

analog reference. Under this value the input is not

acquired

Allowed values:

from 0 to 128 (128 units = 0.625 V) in 1 unit steps

Note: it is useful to cut random or too big offset from

CNC. Set to 0 for normal operation

Loading...

Loading...