INDEX

DS2000 USER’S MANUAL (rev.C)

I.6

I.3 ACCIDENT PROTECTION

The safety instructions provided in this Manual are included to prevent injury

to personnel (WARNINGS) or damage to equipment (CAUTIONS).

WARNING: High Voltage. BUS BAR's can have voltage ≥810V

dc

even after switching off

(capacitive voltage). Discharge Time approx. 6 Minutes.

WARNING: High Voltage. The recovery resistor is connected to the BUS BAR’s and can

have voltage ≥810V

dc

.

WARNING: do not touch recovery resistor during operation to avoid scalds.

CAUTION: it is recommended to disconnect the drive and the EMC filters to carry out the AC

Voltage Tests of EN 60204-1 (1997), par.19.4, in order to not damage the Y-type capacitors

between phases and ground. Moreover the DC voltage dielectric test required by EN 50178

(1997), product family standard, has been carried out in factory as a routine test. The DC

Insulation Resistance Tests of EN 60204-1 (1997), par.19.3, may be carried out without

disconnecting the drive and the EMC filters.

CAUTION: when required for an emergency stop, opening U2-V2-W2 pins and closing motor

phases to resistors, must be preceded by disabling the axis. The delay time must be at least

30 ms.

CAUTION: in case of repetitive switching on and off, waits 1 minute between off and on.

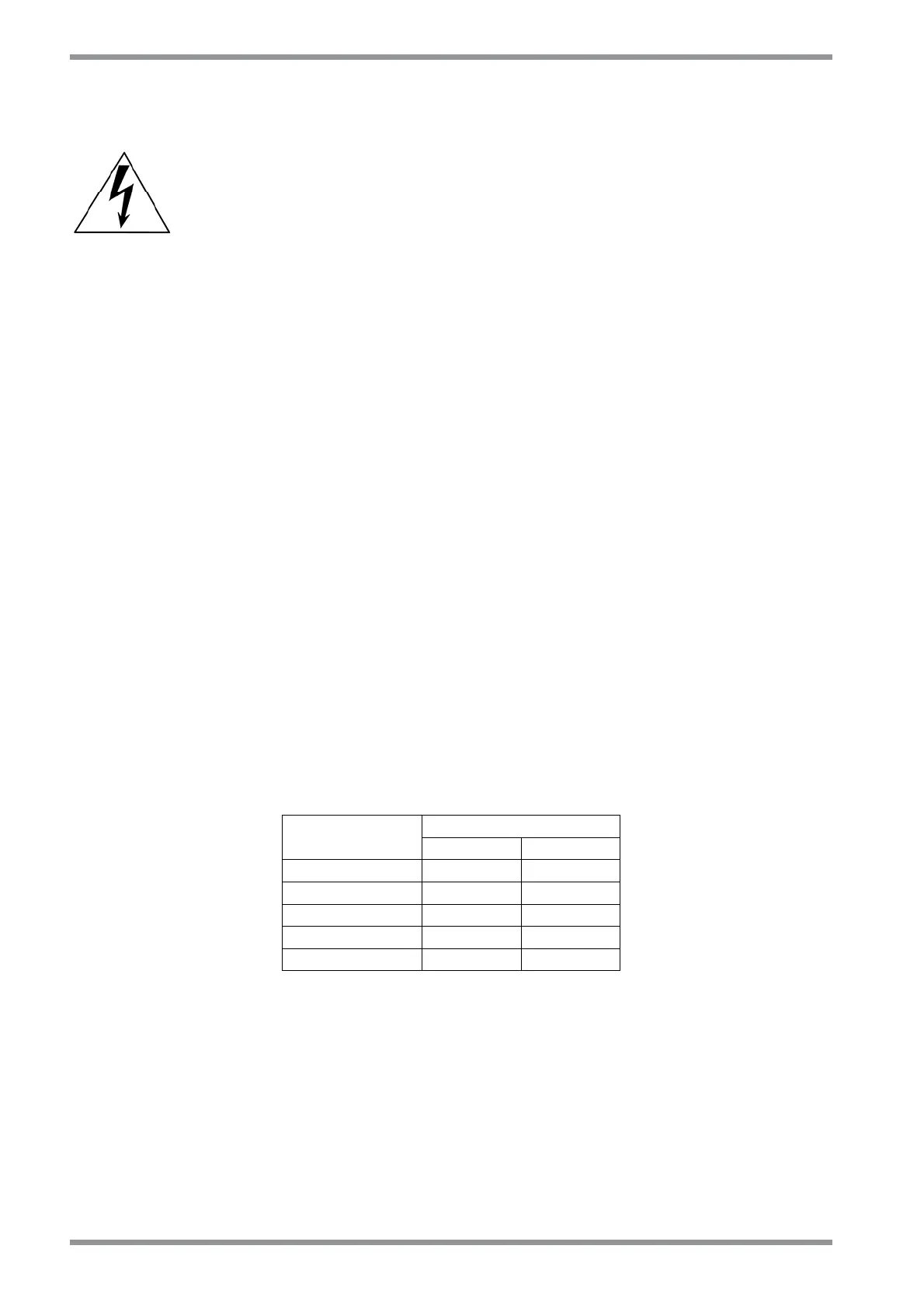

CAUTION: do not exceed the tightening torque of the table (but see proper data sheets for

the tightening torque of input capacitors and power modules and see section 2 of this manual

for the tightening torque of terminal blocks).

Tightening torque

Screw thread

[Nm] [lb in]

M3 1.00 8.85

M4 3.00 26.55

M5 6.00 53.10

M6 8.00 70.80

M8 20.00 177.00

Loading...

Loading...