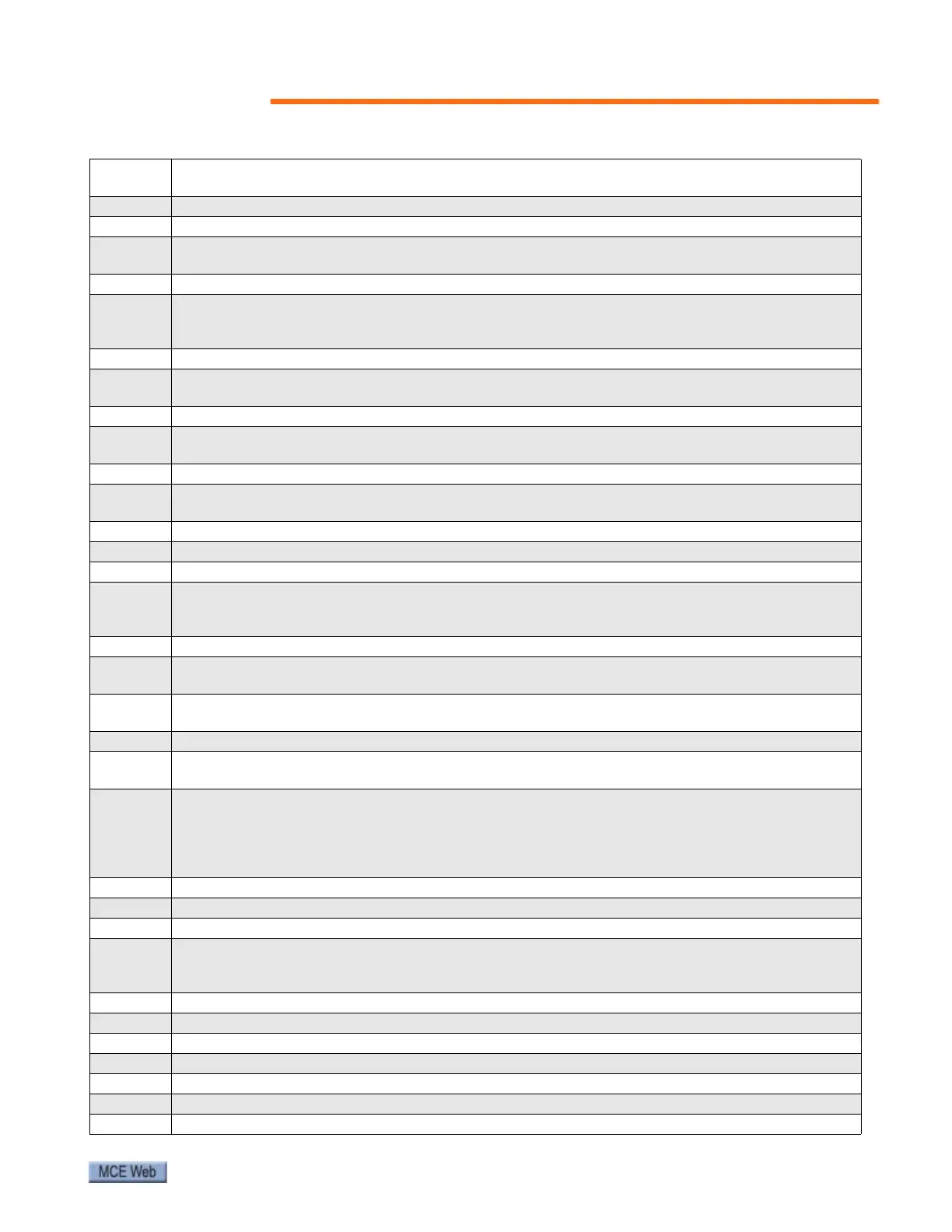

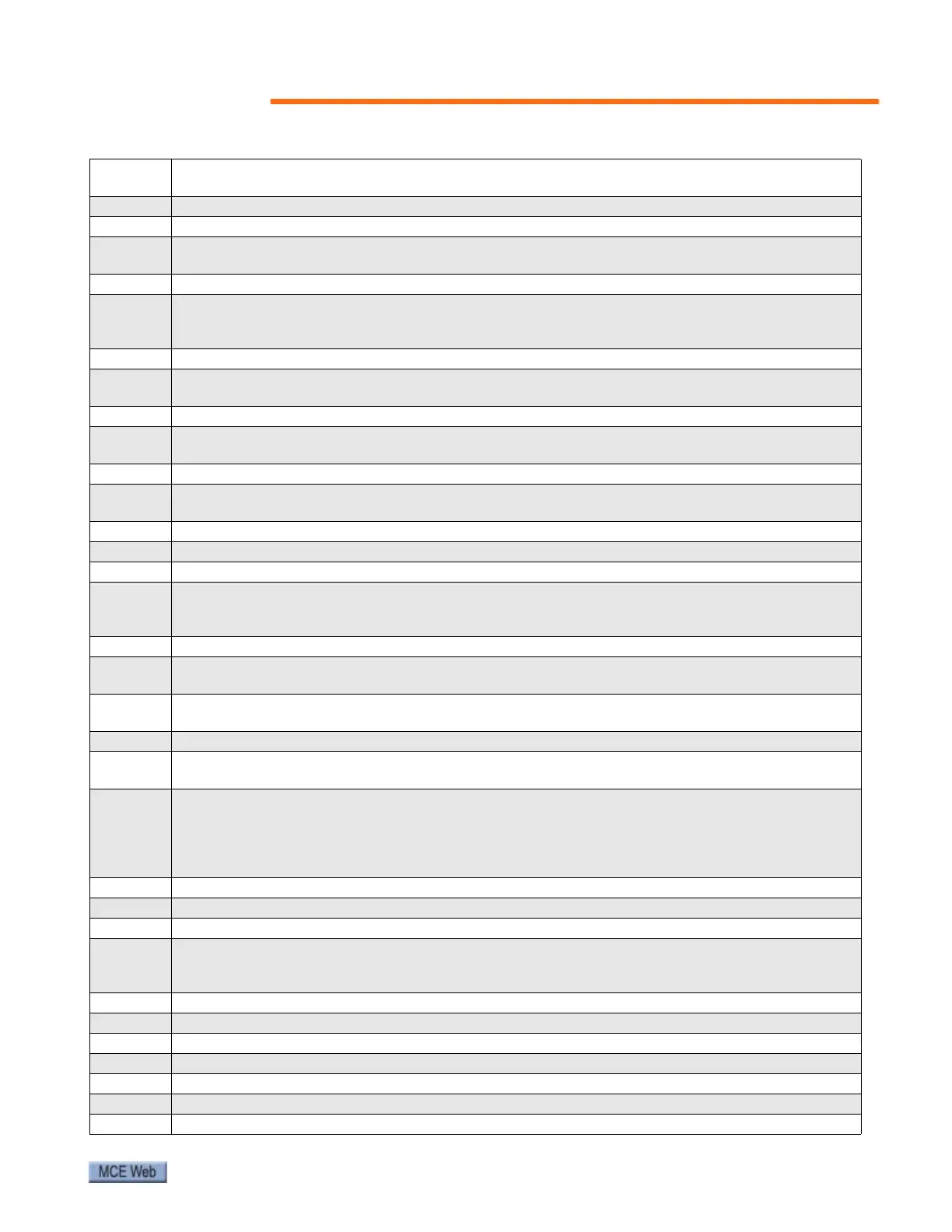

Fault Conditions

55

EEF

EEPROM data corrupted - Drive mode becomes open loop and serial comms will time out with

remote keypad on the drive RS485 comms port.

31 This trip can only be cleared by loading default parameters and saving parameters

EnC1 Drive encoder trip: Encoder power supply overload

189

Check encoder power supply wiring and encoder current requirement. Maximum current =

200mA @ 15V, or 300mA @ 8V and 5V

EnC2 Drive encoder trip: Wire break

190

Check cable continuity Check wiring of feedback signals is correct Check encoder power is set

correctly Replace feedback device If wire break detection on the main drive encoder input is not

required, set Pr 3.40 = 0 to disable the EnC2 trip

EnC3 Drive encoder trip: UVW phase offset incorrect whilst running

191

Check the encoder signal for noise Check encoder shielding Check the integrity of the encoder

mechanical mounting Repeat the offset measurement test

EnC4 Drive encoder trip: Feedback device comms failure

192

Ensure encoder power supply is correct Ensure baud rate is correct Check encoder wiring Replace

feedback device

EnC5 Drive encoder trip: Checksum or CRC error

193

Check the encoder signal for noise Check the encoder cable shielding With EnDat encoders, check

the comms resolution and/or carry out the auto-configuration Pr 3.41

EnC6 Drive encoder trip: Encoder has indicated an error

194 Replace feedback device With SSI encoders, check the wiring and encoder supply setting

EnC7 Drive encoder trip: Initialization failed

195

Re-set the drive Check the correct encoder type is entered into Pr 3.38 Check encoder wiring

Check encoder power supply is set correctly Carry out the auto-configuration Pr 3.41 Replace

feedback device

EnC8 Drive encoder trip: Auto configuration on power up has been requested and failed

196

Change the setting of Pr 3.41 to 0 and manually enter the drive encoder turns (Pr 3.33) and the

equivalent number of lines per revolution (Pr 3.34) Check the comms resolution

EnC9

Drive encoder trip: Position feedback selected is selected from a Solutions Module slot which does

not have a speed / position feedback Solutions Module fitted

197 Check setting of Pr 3.26 (or Pr 21.21 if the second motor parameters have been enabled)

EnC10

Drive encoder trip: Servo mode phasing failure because encoder phase angle (Pr 3.25 or Pr

21.20) is incorrect

198

Check the encoder wiring. Perform an autotune to measure the encoder phase angle or manually

enter the correct phase angle into Pr 3.25 (or Pr 21.20). Spurious EnC10 trips can be seen in

very dynamic applications. This trip can be disabled by setting the speed threshold in Pr 3.08 to

a value greater than zero. Caution should be used in setting the over speed threshold level as a

value which is too large may mean that an encoder fault will not be detected.

ENP.Er Data error from electronic nameplate stored in selected position feedback device

176 Replace feedback device

Et External trip from input on terminal 31

6

Check terminal 31 signal Check value of Pr 10.32 Enter 12001 in Pr xx.00 and check for parame-

ter controlling Pr 10.32 Ensure Pr 10.32 or Pr 10.38 (=6) are not being controlled by serial

comms

HF01 Data processing error: CPU address error

Hardware fault - return drive to supplier

HF02 Data processing error: DMAC address error

Hardware fault - return drive to supplier

HF03 Data processing error: Illegal instruction

Hardware fault - return drive to supplier

HF04 Data processing error: Illegal slot instruction

Table 20. CT Drive Fault Displays

Loading...

Loading...