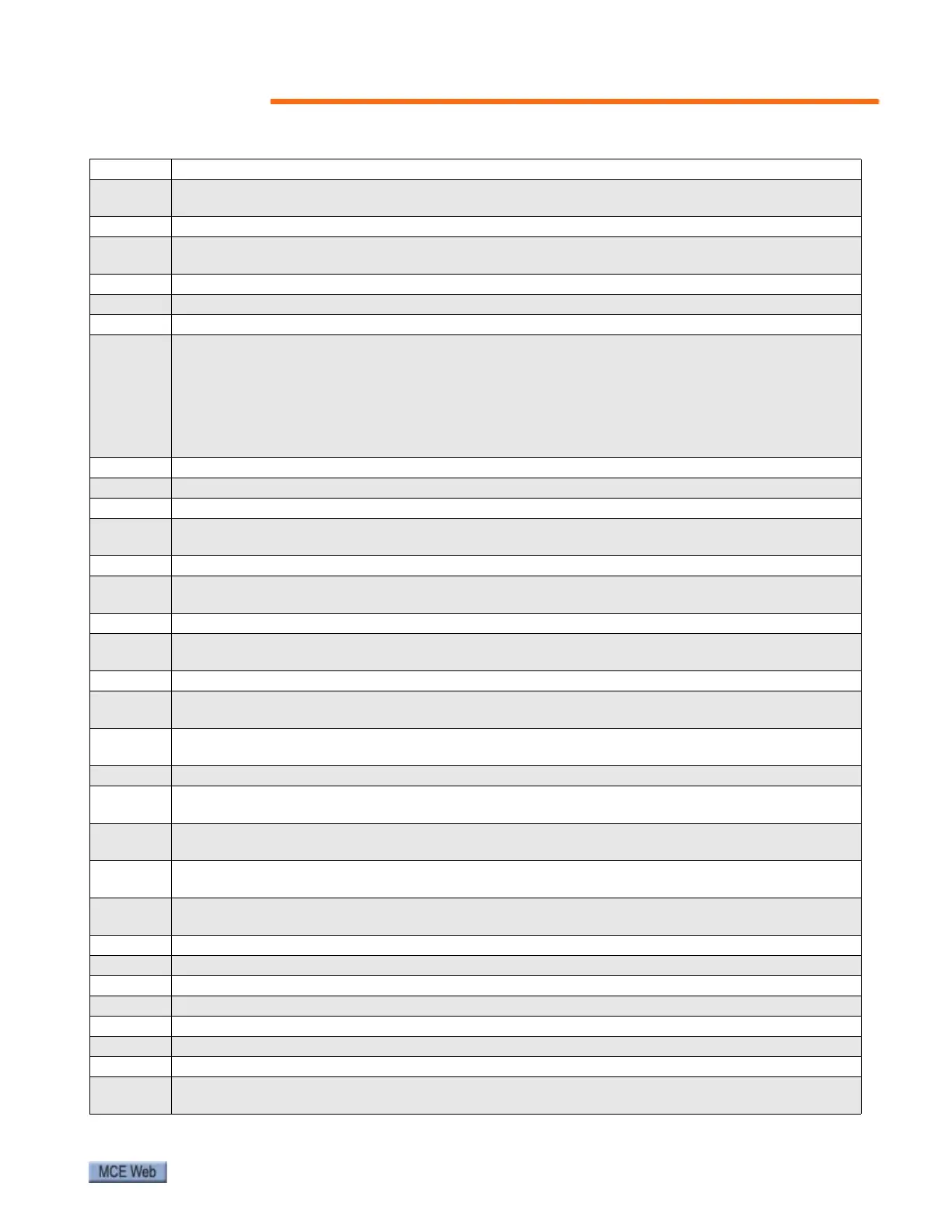

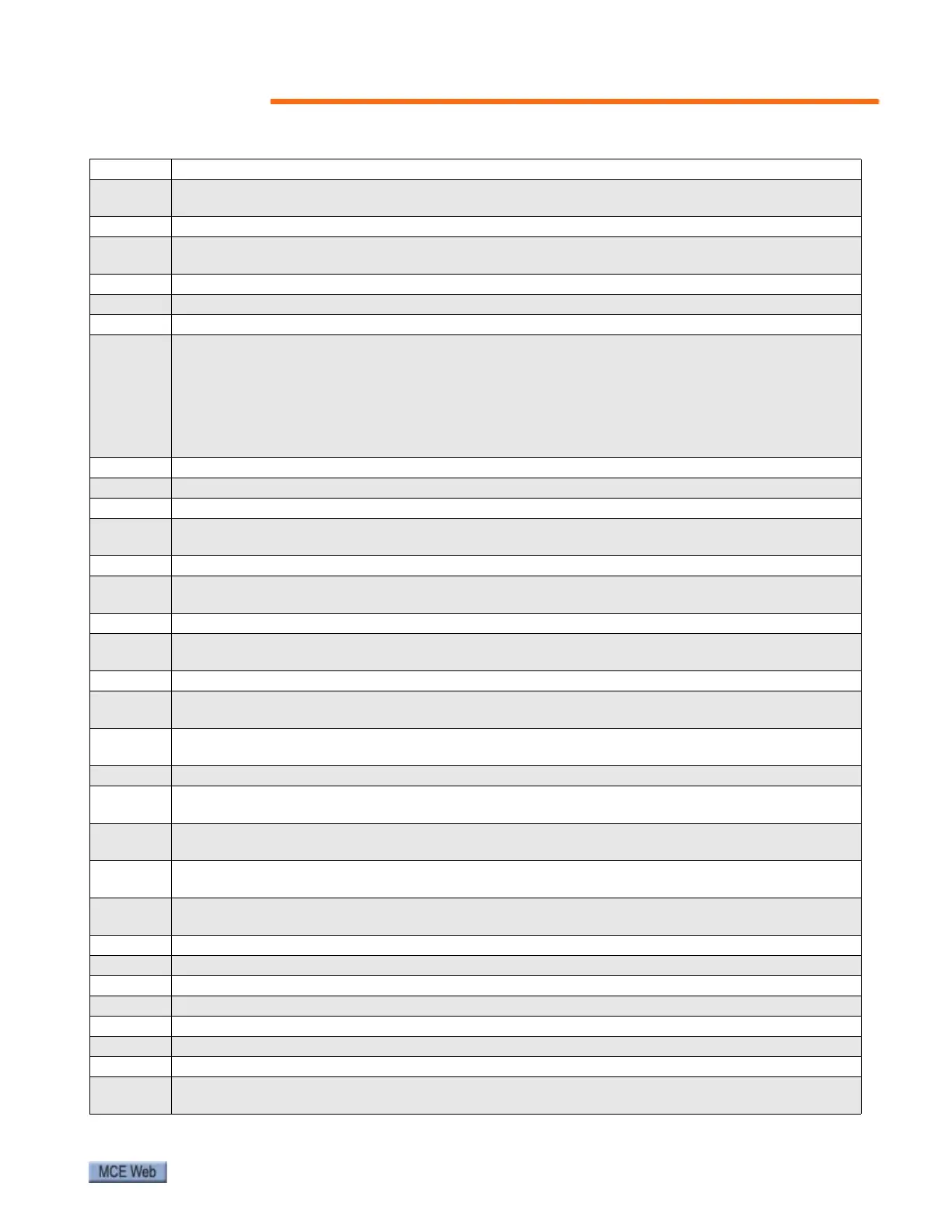

Fault Conditions

59

Ph.P Power module phase loss detection

107

Ensure all three phases are present and balanced

Check input voltage levels are correct (at full load)

PS Internal power supply fault

5

Remove any Solutions Modules and reset Check integrity of interface ribbon cables and connec-

tions (size 4,5,6 only) Hardware fault - return drive to supplier

PS.10V 10V user power supply current greater than 10mA

8 Check wiring to terminal 4 Reduce load on terminal 4

PS.24V 24V internal power supply overload

9

The total user load of the drive and Solutions Modules has exceeded the internal 24V power sup-

ply limit. The user load consists of the drive digital outputs plus the SM-I/O Plus digital outputs,

or the drive main encoder supply plus the SM-Universal Encoder Plus and SM-Encoder Plus

encoder supply.

• Reduce load and reset

• Provide an external 24V >50W power supply

• Remove any Solutions Modules and reset

rS Failure to measure resistance during autotune or when starting in open loop vector mode 0 or 3

33 Check motor power connection continuity

SCL Drive RS485 serial comms loss to remote keypad

30

Refit the cable between the drive and keypad Check cable for damage Replace cable Replace key-

pad

th Motor thermistor trip

24

Check motor temperature Check thermistor continuity Set Pr 7.15 = VOLt and reset the drive to

disable this function

thS Motor thermistor short circuit

25

Check motor thermistor wiring Replace motor thermistor Set Pr 7.15 = VOLt and reset the drive

to disable this function

tunE Autotune stopped before completion

18

The drive has tripped out during the autotune The red stop key has been pressed during the

autotune The secure disable signal (terminal 31) was active during the autotune procedure

tunE1

The position feedback did not change or required speed could not be reached during the inertia

test (see Pr 5.12)

11 Ensure the motor is free to turn i.e. brake was released Check encoder coupling to motor

tunE2

Position feedback direction incorrect or motor could not be stopped during the inertia test (see Pr

5.12)

12

Check motor cable wiring is correct Check feedback device wiring is correct Swap any two motor

phases (closed loop vector only)

tunE3

Drive encoder commutation signals connected incorrectly or measured inertia out of range (see

Pr 5.12)

13

Check motor cable wiring is correct Check feedback device U,V and W commutation signal wiring

is correct

tunE4 Drive encoder U commutation signal fail during an autotune

14 Check feedback device U phase commutation wires continuity Replace encoder

tunE5 Drive encoder V commutation signal fail during an autotune

15 Check feedback device V phase commutation wires continuity Replace encoder

tunE6 Drive encoder W commutation signal fail during an autotune

16 Check feedback device W phase commutation wires continuity Replace encoder

tunE7 Motor number of poles set incorrectly

17

Check lines per revolution for feedback device Check the number of poles in Pr 5.11 is set cor-

rectly

Table 20. CT Drive Fault Displays

Loading...

Loading...