Cleaning

Cleaning recommendations

03.06.2014 53

¾ Allow the machine and sealing bar to cool down.

¾ Store empty, new film pouches outside the room in a clean, dry

place during the cleaning procedure.

¾ Remove all waste (e.g. product scraps, film trim) on or around the

machine.

¾ Remove the following components:

– Sloping insert with with support angle.

– Filling plate.

– Sealing bar, see Section 7.3.1 "REMOVE THE SEALING BAR".

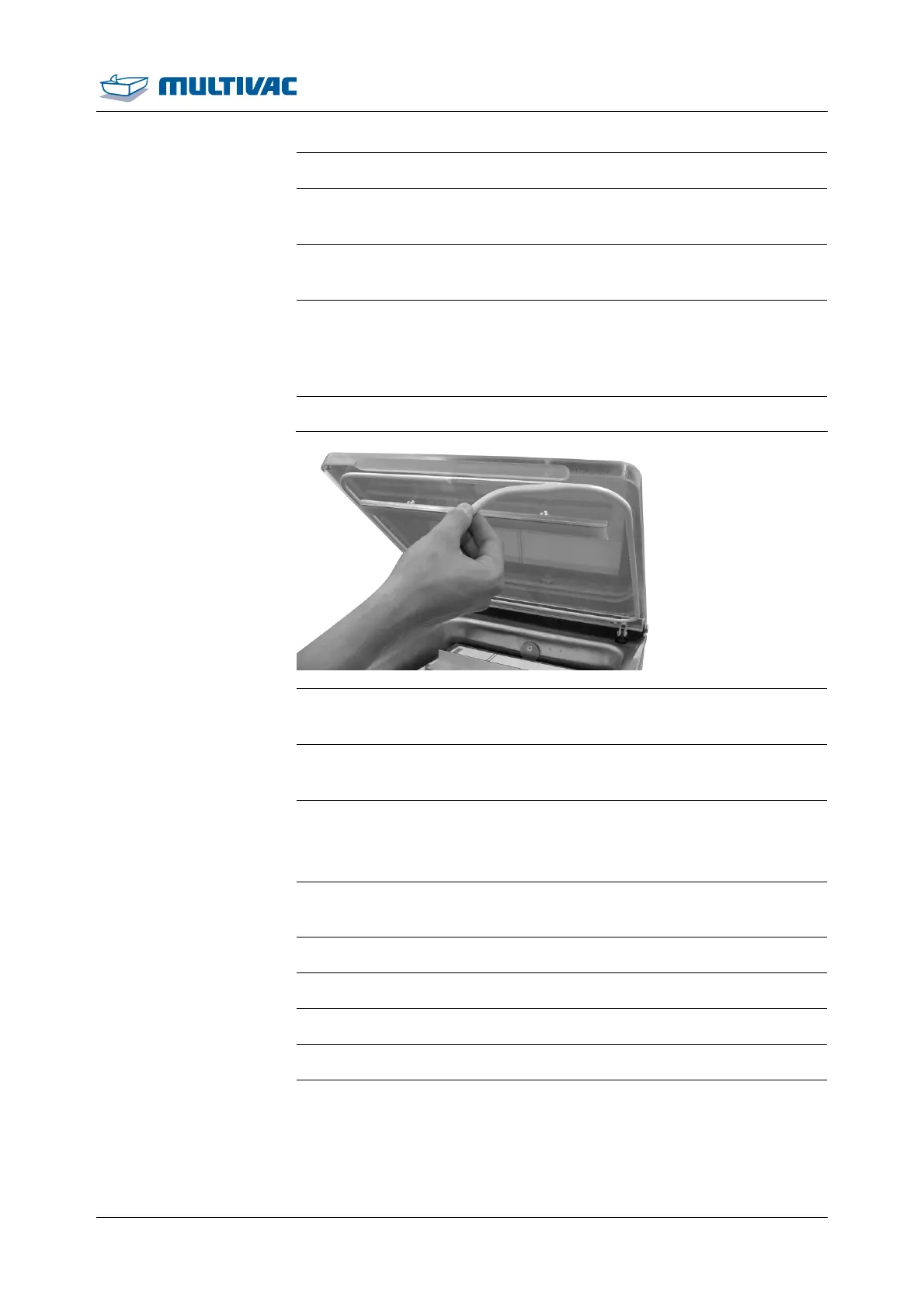

¾ Check chamber lid gasket for dirt or contamination.

¾ If there is dirt or contamination, remove the chamber lid gasket

from the groove.

¾ Take the removed components to a separate room suitable for

wet cleaning

¾ Clean dismantled components manually with cleaning solution.

¾ Only clean the Teflon tape of the sealing bar manually with a

soft cloth or a soft brush.

¾ Wait until the contact time has elapsed (see instructions of

cleanser manufacturer).

¾ Wipe with new cloth and water of drinking quality.

¾ Inspect for dirt and cleanser residues.

¾ If necessary, perform another manual cleaning and wipe it off.

¾ Disinfect the removed components with disinfectant.

¾ Wait until the contact time has elapsed (see instructions of disin-

fectant manufacturer).

Loading...

Loading...