42

Subject to modication

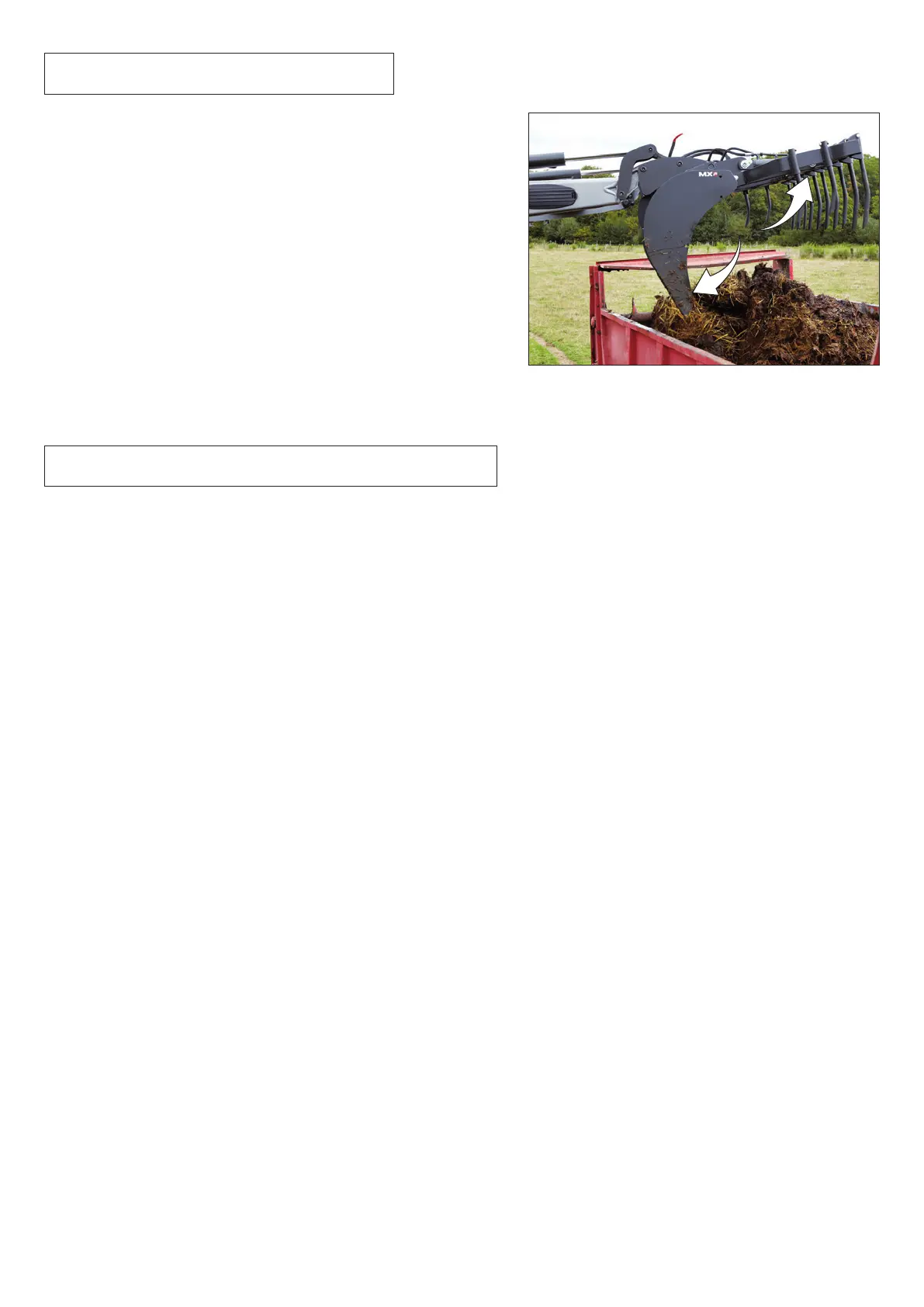

18. AUTO-UNLOAD System

The bucket/grab synchronisation (optional) operates both ways:

— Opening the grab/Tipping the bucket.

— Crowding the bucket/Closing the grab.

The AUTO-UNLOAD System only operates if the loader is tted

with a 3rd function.

e-PILOT S control: see manual specic to e-PILOT S (function:

AUTO-UNLOAD System).

NOTE: To optimise use of the AUTO-UNLOAD System, we

recommend activating the system while dumping into a trailer,

when the implement is in the horizontal position.

■

19. Safety when lifting and dumping

In compliance with standard EN 12525 + A2 2010, it can be disengaged for working when no one is near the load.

The movements can then be carried out, with no loss of power or speed of execution.

Uniquely, this equipment is compatible with the Shock Eliminator and the notched oating position.

■

19.1 Extract from the Front Loaders standard EN12525 + A2 2010:

"4.4.4 Protection against unintentional lowering

If the front loader is also designed for lifting operations requiring the presence of someone near the load when the loader

is in raised position, the hydraulic circuit of the lifting arm rams must, in compliance with Annex E, be tted with a safety

device to prevent accidental lowering of the lifting arm. This device must remain active in the event of a failure of the

control circuit's power supply.

If this safety device can be switched on/o or activated/deactivated for operations that do not require the presence of

someone near the load, then the following additional specications apply:

— it must be possible to switch on/o or activate/deactivate the safety device from the driving position;

— it must be possible to switch on or activate the safety device from the ground without being close to the load;

— the operating device to switch o or deactivate the safety device must be designed and located so that the operator

cannot operate it unintentionally;

— the status (on/o or activated/deactivated) of the safety device must be clearly indicated and clearly visible from the

driving position and from the loading area.

In compliance with 7.1.2, the correct operating method, along with appropriate warnings, must be explained in the

instruction manual.

The loader must be tted with a warning stating that for lifting operations requiring the presence of someone near the

load, the safety device must be switched on (activated) when the loader is in the raised position (see 7.2).

Information on the use of front loaders that are not designed for lifting operations requiring the presence of an operator

near the load when the loader is in raised position must comply with 7.1.4 and 7.2. “

” Annex E (normative)

Test method and acceptance criteria for means of avoiding unintentional lowering

E.1 Terms and denitions

E.1.1

discharge device

hydraulic valve(s) used to simulate a break in the loader's hydraulic lines.

E.1.2

test load

Loading...

Loading...