44

Subject to modication

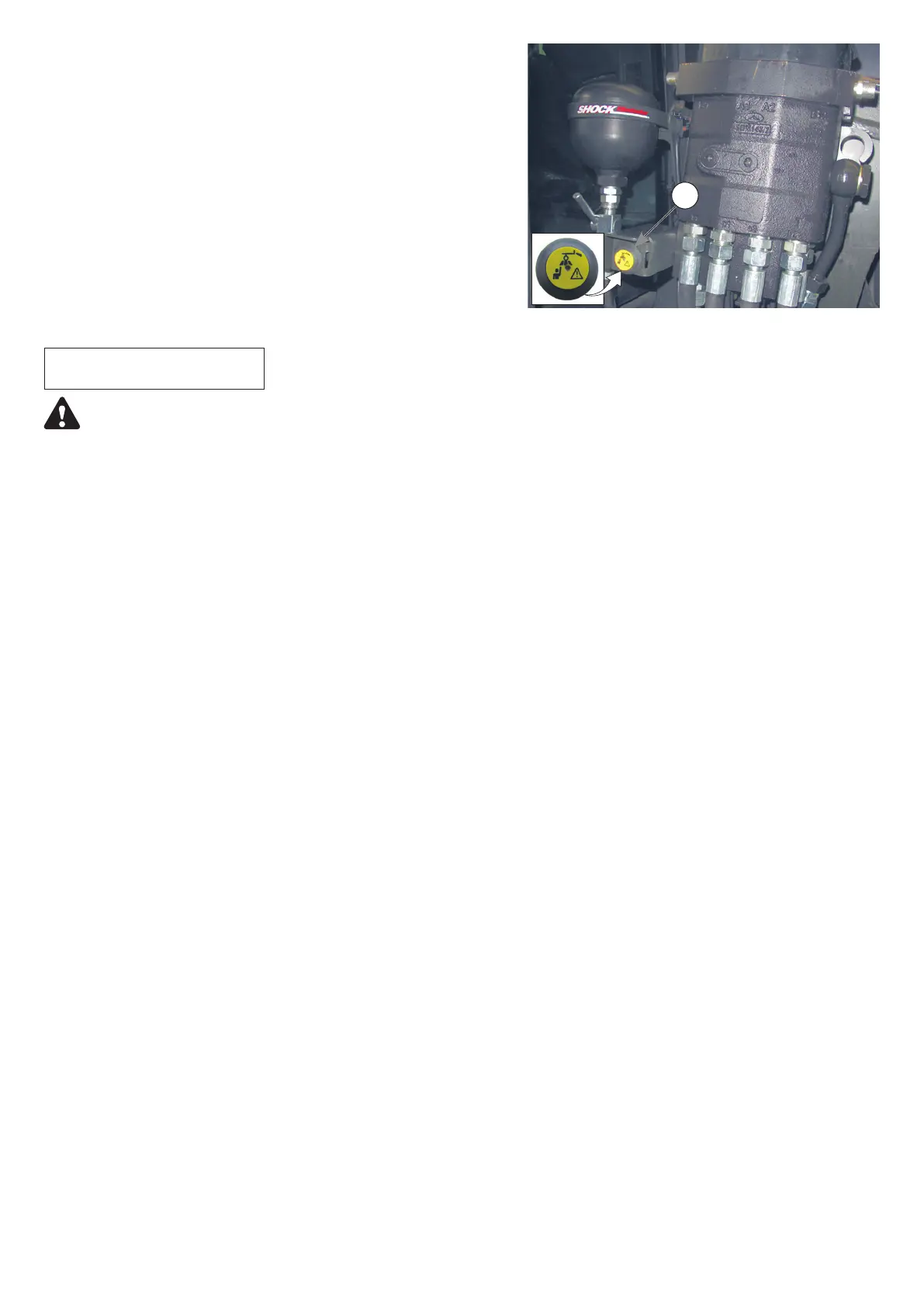

Button (4) is used exclusively to reactivate the safety device from

outside the cab.

In this case, the red indicator lights go o.

■

4

20. Maintenance

Drain the tractor's hydraulic circuit regularly and change the lters in accordance with the

manufacturer's recommendation.

Contaminated oil ceases to lubricate, causing wear to all the hydraulic components (pumps,

control valves, rams). Even clear oil may be spent.

Maintenance operations must be performed by competent persons, authorised by the dealer. If this is not the case,

these operations shall come under the sole responsibility of the person carrying out the work.

PPE (Personal Protective Equipment) must be worn during all maintenance operations (please refer to the "PPE table".

See the "Safety Rules" chapter).

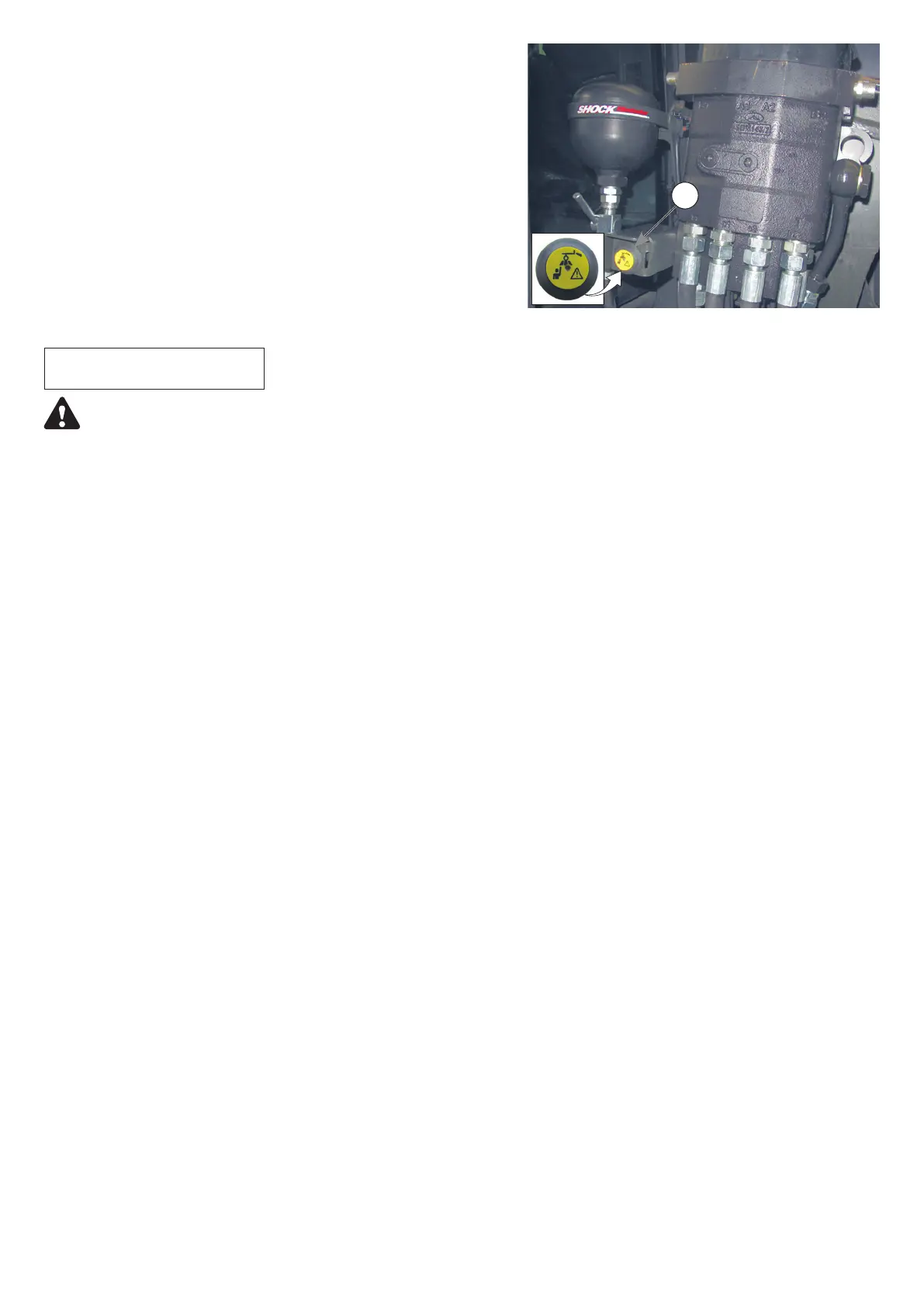

For loader maintenance operations, never work on mechanical parts under stress or on a pressurised circuit, hydraulic

part, or electrical circuit that is switched on.

For tractor maintenance operations, it is strongly recommended to unhitch the loader. Unhitching is a simple, quick

operation that provides the best guarantees of safety and eciency for tractor maintenance.

For any work with the lifted loader, the loader must be locked in position:

Unlocking the MACH System, or closure of the lifting rams supply valve for a loader without MACH System. (See the

"LOADER UNHITCHING" chapter).

■

Loading...

Loading...