45

Subject to modication

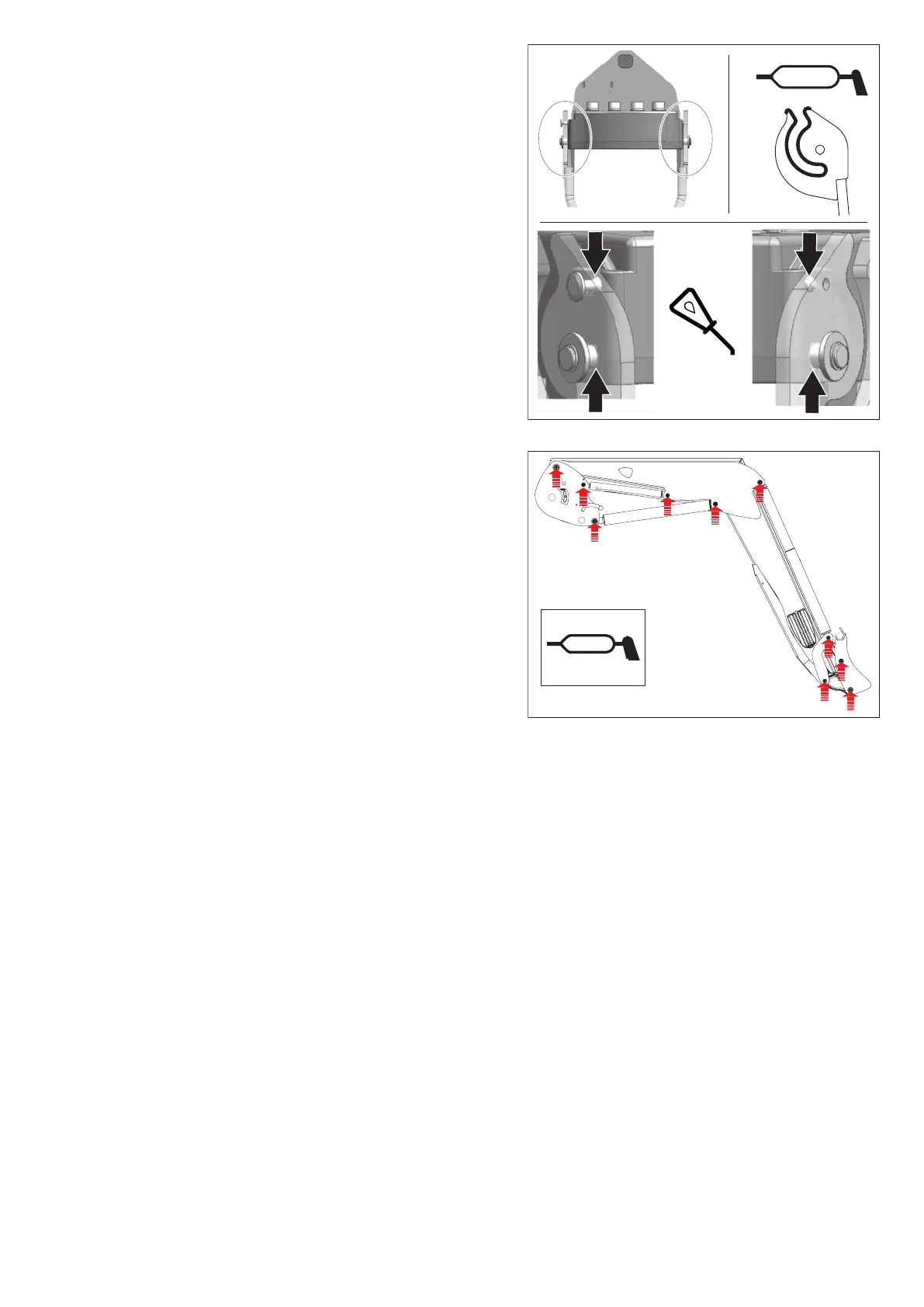

Lubricate the MACH System locking system every 3 months.

■

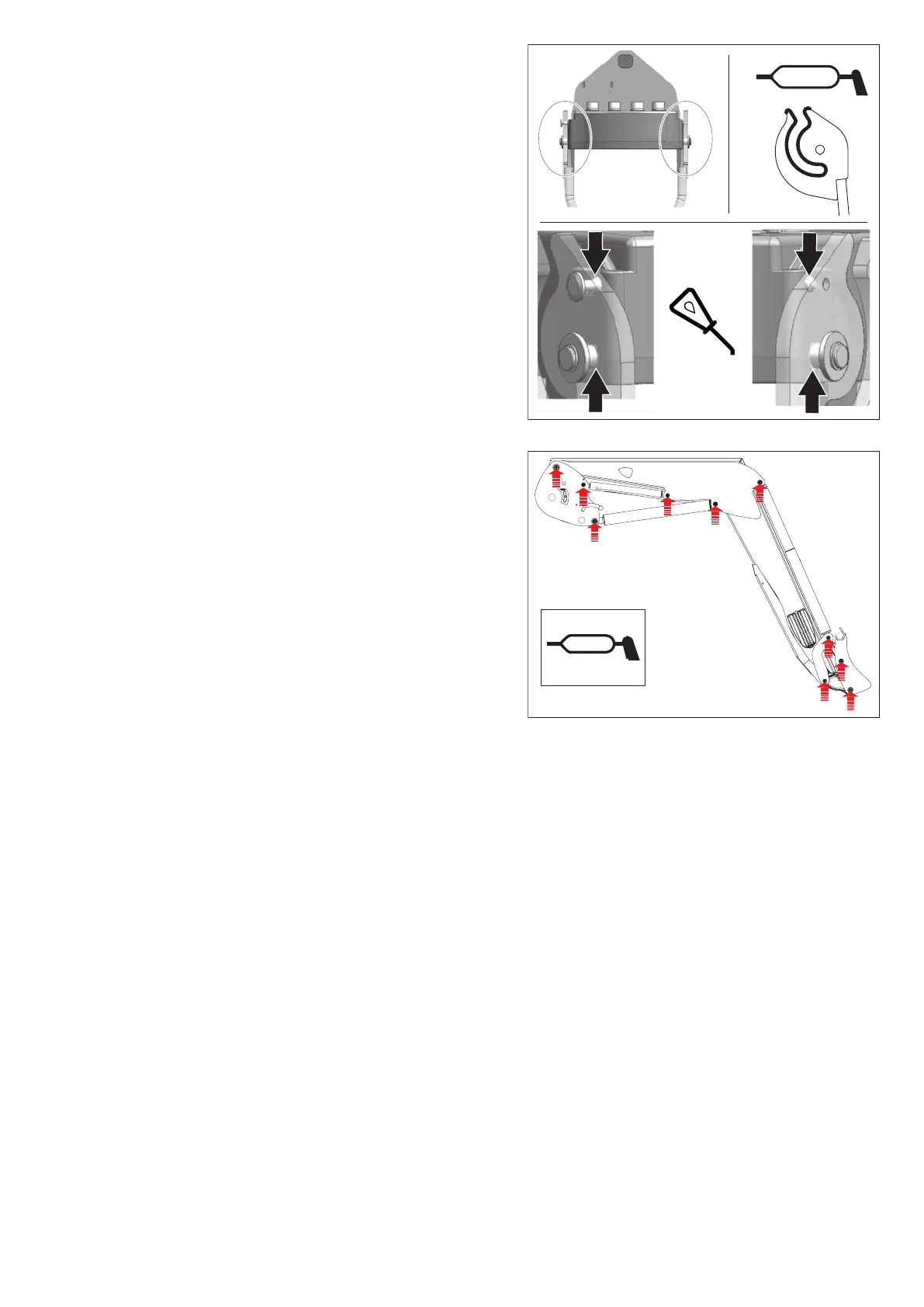

Lubricate every 10 hours and after each wash (water drives

grease out), particularly after using a pressure washer.

See the lubrication points opposite.

Recommended type of grease for maintenance: NLGI 2

When using a pressure washer, do not direct the jet of water onto

the electric components.

Clean the implement and the front of the loader after every use.

Slurry acid, fertiliser and silage can damage paint, steel and pivot

points.

■

Every month, or more often with heavy use, check:

— The condition of the loader's pivot points. As required, replace wear bushes and/or the pins.

— The wear rings must be replaced if they are less than 1 mm thick.

— The tractor's hydraulic oil level and the sealing of the hydraulic system. If you nd any internal or external leaks on

hydraulic components (rams, pipes, connectors, Mach, couplings, etc.), contact your dealer.

— Condition of the hoses: replace them if any cracks or oil seepages appear.

— The correct operation of the monolever (cables, play, locking, etc.).

— The condition of the electric cabling. Contact your dealer if any connectors or cables are damaged.

— The mechanical condition (any cracks, distortion, end stop matting, play, parking stands, etc.)

— Contact your dealer if there is any abnormal wear.

— Disposal: please contact your dealer or a company specialising in materials recycling.

— Check the tightness of the bracket after 10 and 50 hours work, then every 100 hours or at each engine draining of the

tractor. Contact your dealer if there is any loosening.

IMPORTANT: Any fasteners/screws needing to be retightened must be inspected, replaced if necessary, cleaned and

reassembled using thread locking compound.

Loading...

Loading...