N

E

M

O

P

U

M

P

E

N

Continued Page 2.0R

N

E

M

O

P

U

M

P

E

N

2 DESCRIPTION AND GENERAL DATA

PAGE

2.0

Date Name Signed Revision: 2

issued 03.08.98 Mangel Substitute for issue

approved 04.08.98 Hantschk of 18.03.94

released 05.08.98 Hantschk

text no. 30100

copy to: 95

2 Description

The NEMO

®

pump is a progressing cavity

pump.

The main components which determine the

system discovered by Professor René Moineau

are a rotating part, called the rotor and a sta-

tic part, called the stator.

The rotor is a helical screw with an extreme-

ly large pitch, large thread depth and small

centre diameter with round cross-section for

1/2-geometry and elliptical cross-section for

2/3-geometry. The stator has a two start or

resp. 3 start thread and is double or resp. 1.5

the pitch length of the rotor. This provides

space for the medium between the rotor and

stator. When the rotor turns round inside the

stator the medium moves continuously from

the inlet to the outlet.

The universal NEMO

®

pump system unifies

many positive characteristics of other pump

types:

■ Like centrifugal pumps NEMO

®

pumps

have no suction or pressure valves, but do

have a stable flow rate in proportion to the

number of revolutions.

■ Like piston pumps NEMO

®

pumps have a

suction capability of up to 8.5 m vacuum

metric.

■ Like membrane and peristaltic pumps the

NEMO

®

pump can transport every type of

inhomogenous, gaseous and abrasive media,

as well as those that are not of a liquid con-

sistency or contain solids and/or fibrous mate-

rial.

■ Like gear pumps and screw pumps the

NEMO

®

pump is capable of coping with high

medium viscosities.

■ Like piston, membrane, gear or screw

pumps the NEMO

®

pump can perform dosing

operations.

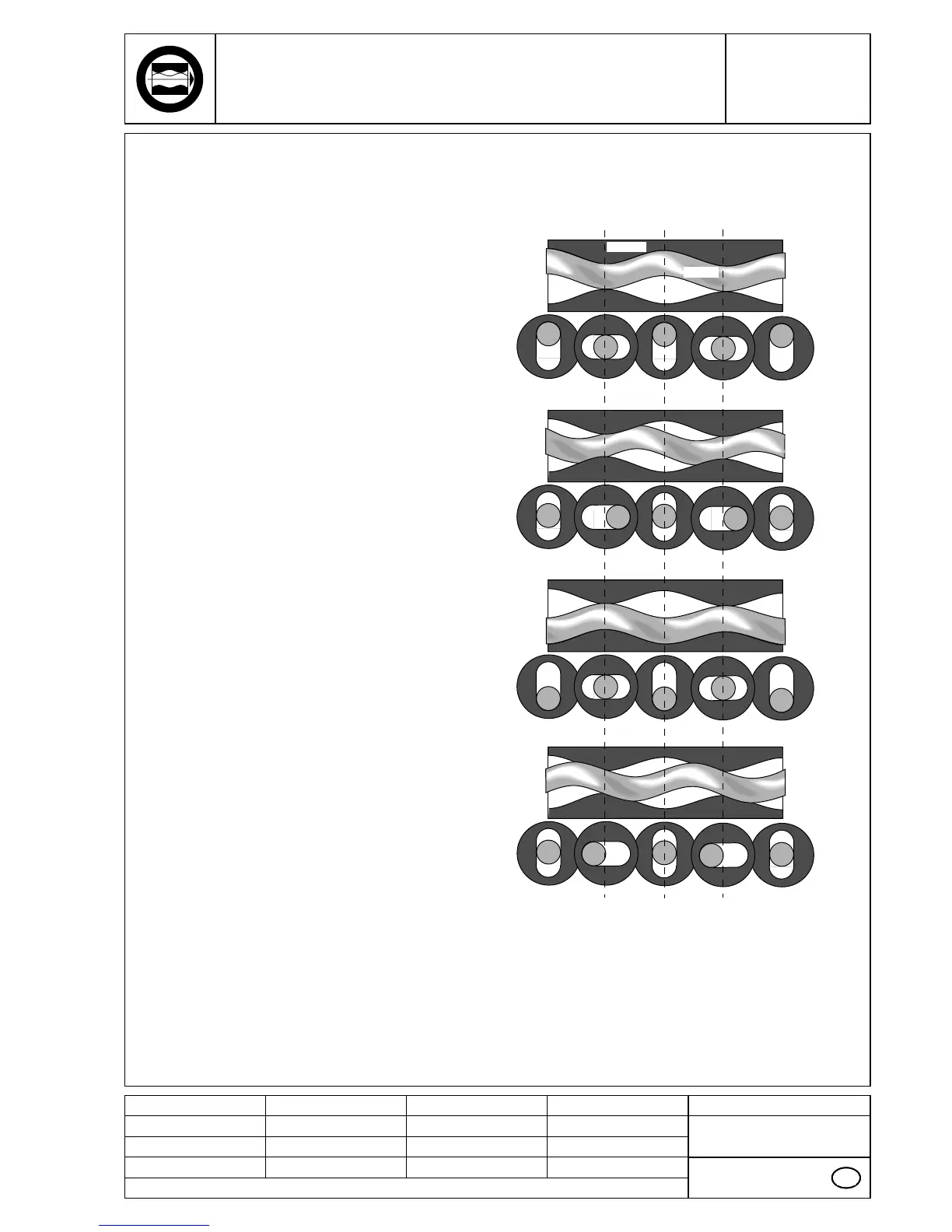

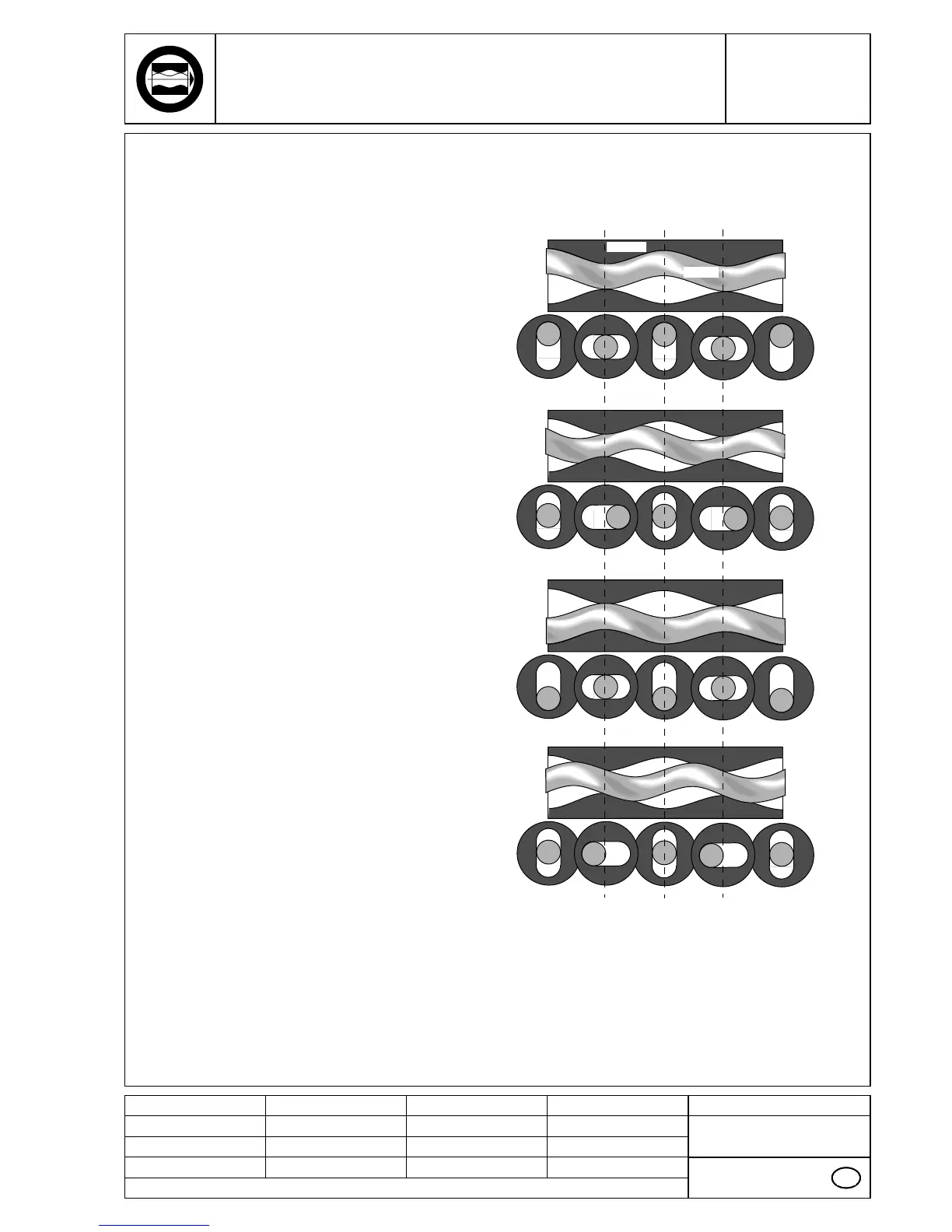

Length and cross-sections through the rotor

and stator with 1/2-geometry during a

rotation.

0°/360°

90°

180°

270°

Rotor-

Stellun

Loading...

Loading...