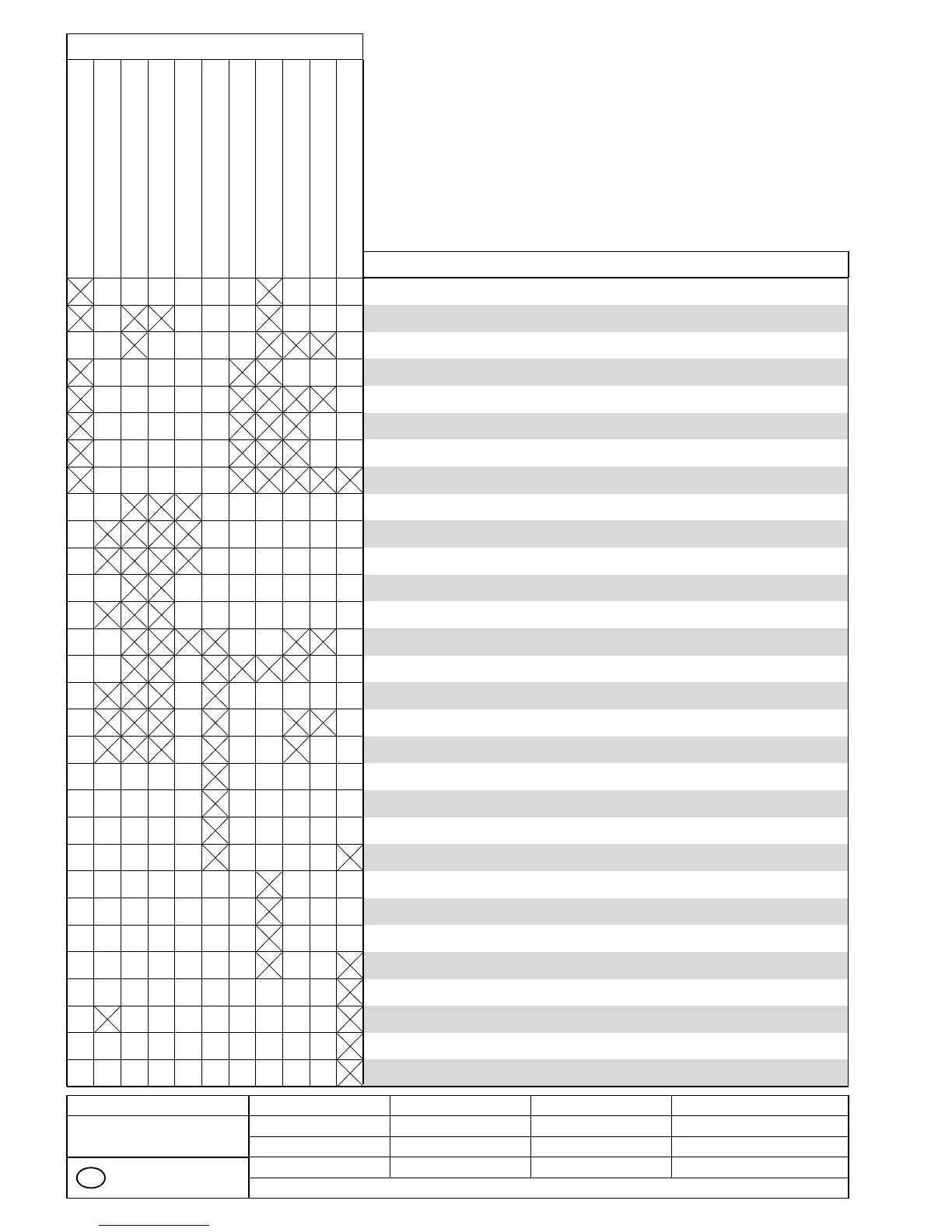

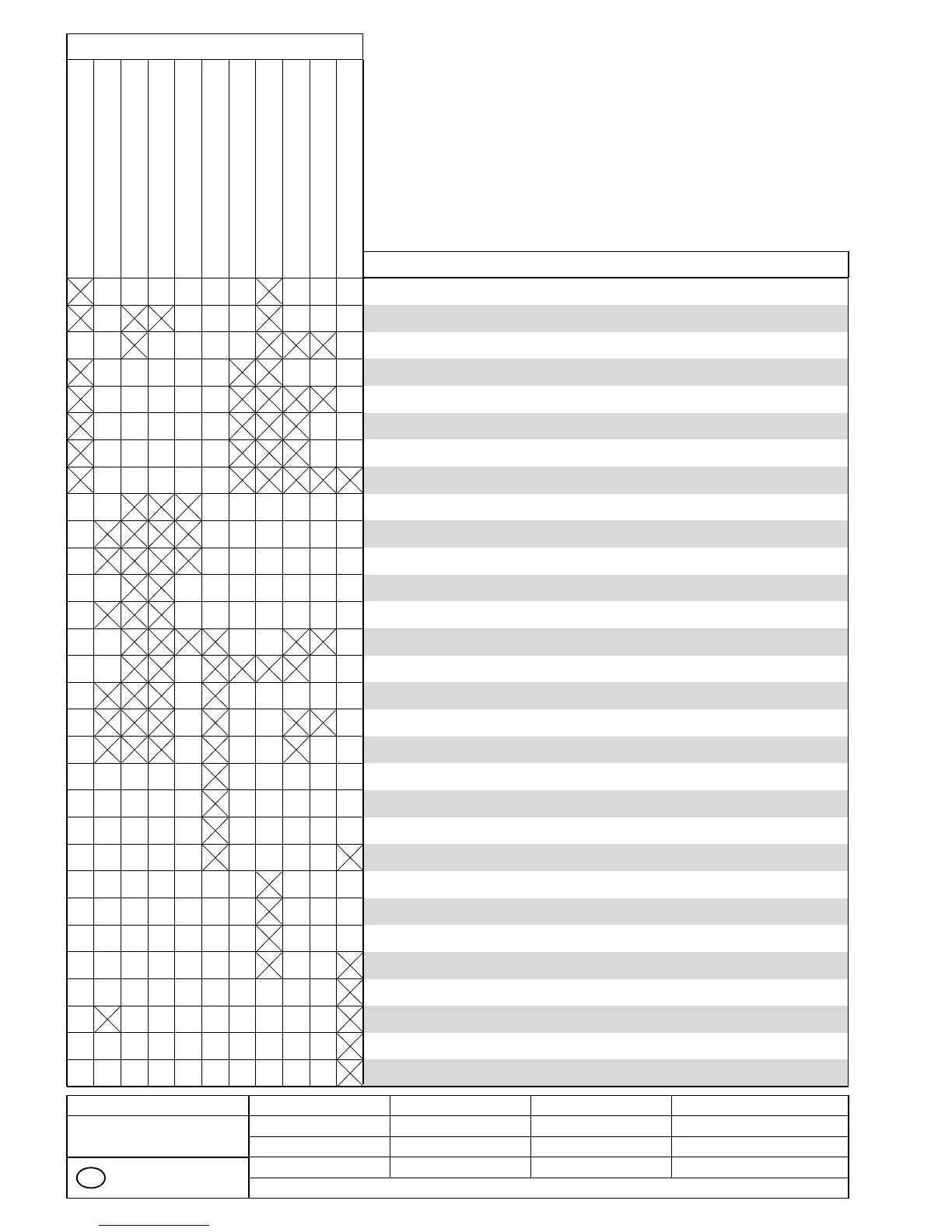

The pump is no longer starting

The pump is no longer sucking

The pumped medium is too little

The pressure is too low

The pumped medium is unstable

The pump is running loudly

The pump is stuck

The drive is overloaded

The stator life time is too short

The rotor life time is too short

The shaft seal is leaking

Possible Problems

In new pumps or stators : the static friction is too great.

The pump electrical equipment is not compatible with the electrical supply.

There are foreign bodies in the pump.

The stator has swollen, the elastomer is not compatible with the medium.

The liquid medium sediments or hardens when left to stand.

The suction pipe is leaking.

The rpm is too low.

The suction is too great or pressure too low (cavitation).

The stator is worn out, or temperature of liquid is too low.

The rotor is worn out.

The pump and drive are not axially aligned.

The roller bearings are destroyed.

The viscosity is too high.

The stuffing box is incorrectly tightened.

Mechanical seal : rotation is incorrect.

Mechanical seal : elastomers damaged, swollen or brittle.

The pressure is too high.

The temperature of the liquid medium is too high, the stator is too ductile.

The solids content of the medium is too high and leads to blockages.

There is air in the suction pipe.

The shaft seal is leaking.

With reduced diameter rotors : operating temperature has not been reached.

The pump is running dry.

The stator material is brittle.

The joints are worn out.

The elastic element of the coupling is worn out.

The rpm is too high.

The specific weight of the medium is too high.

The packing is not suited to the liquid medium.

Mechanical seal : mechanical seal and mating ring have failed.

Possible Causes ( Remedy overleaf)

The NEMO

®

-pump is a well established product

which was thoroughly tested before leaving the

factory. If you use the pump in keeping with your

Order Specification and treat it in accordance with

our Operating and Maintenance Instructions, it

will run satisfactorily for a long period of time.

Revision: Date Name Signed

Substitute for issue issued 20.09.95 Mangel

of approved 21.09.95 Eitler

text no. 30100

released 22.09.95 Hantschk

copy to:

GB

Loading...

Loading...