Continued Page 10.0R

N

E

M

O

P

U

M

P

E

N

10 DISMANTLING AND ASSEMBLY

OF THE ROTATING PARTS

PAGE

10.0

date name signed revision: 1

issued 19.12.05 Mangel substitute for the issue

approved 20.12.05 Denk dated 25.06.03

released 20.12.05 Denk

text no. 30100

copy to:

10 Dismantling and Assembly of the Rotating Parts

with Pin Joints with SM-Pin Joint Seal

(basic joint size NM015 - NM125)

10.1 Removal of Rotor and Coupling Rod

Where a pump is fitted with a ceramic rotor (1999) the following operations

should be carried out with great care. Do not use any force or sharp tools!

Special care must be taken to prevent heavy strokes, vibrations or impact

by a hammer.

For removal of the rotor (1999) and coupling rod (1998) the pin joints should

be dismantled as follows:

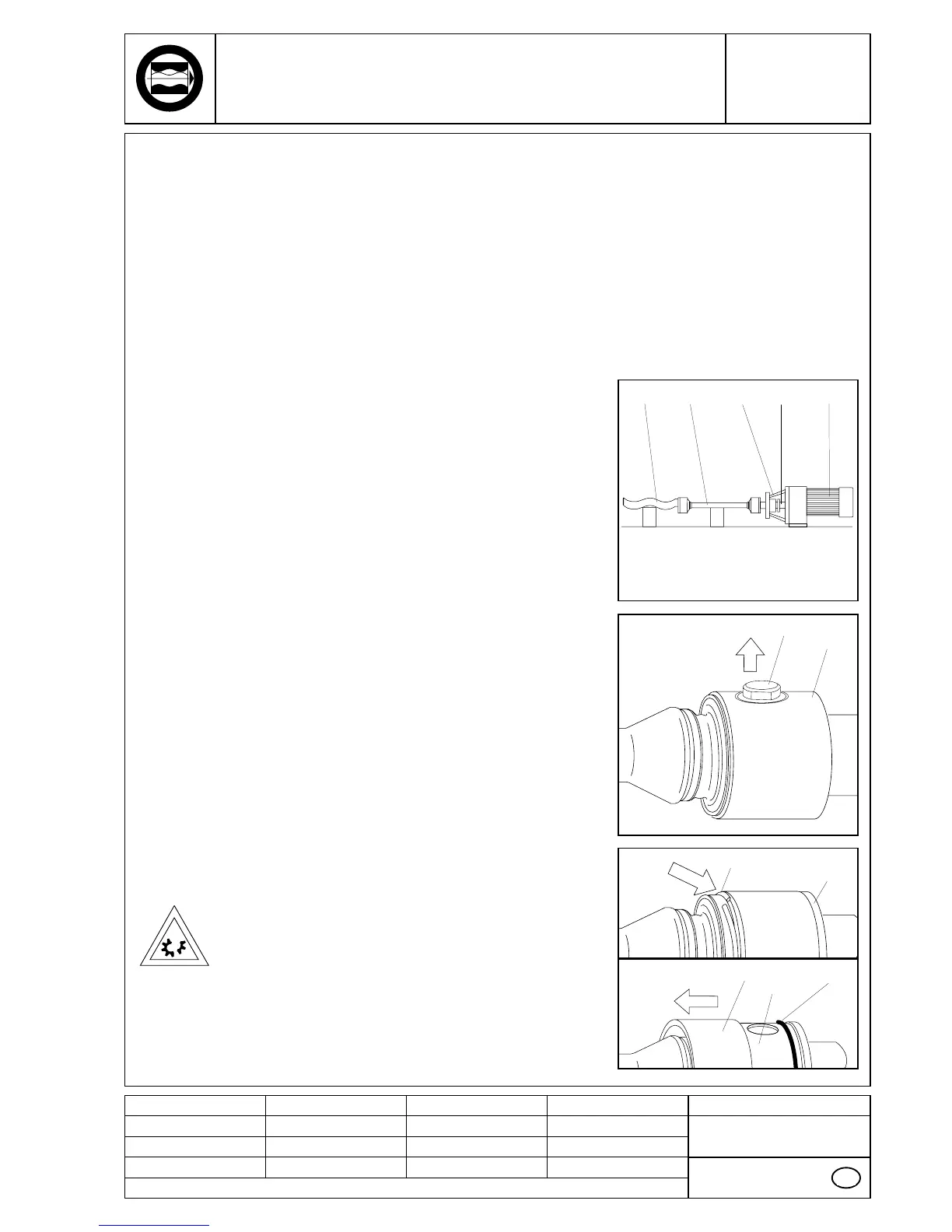

Place the dismantled unit – consisting of drive stool

(0085) with drive (A) and connecting shaft (1050),

coupling rod (1998) and rotor (1999) – on the work-

bench with a wooden block supporting the rotor

(1999).

Basic joint size NM125:

Unscrew the wear sleeves (5440) from the head of

rotor (1999) or connecting shaft (1050)

Basic joint size NM021 - NM105:

Push circlip (5065) out of its groove and slip off over

the head of rotor (1999 or connecting shaft (1050).

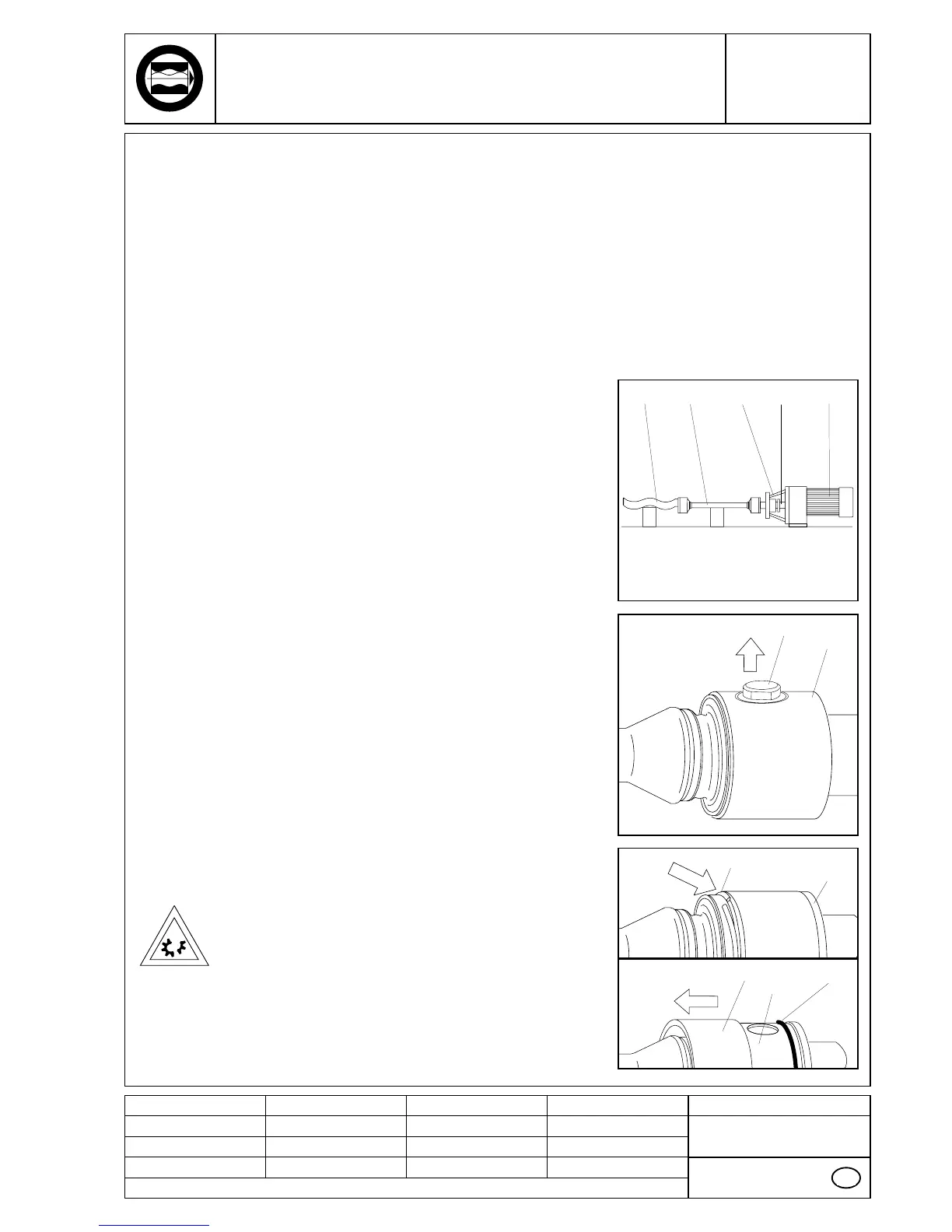

Pumps fitted with a ceramic rotor (1999):

Carefully turn safety sleeve (5115) with a squeeze

belt wrench, and remove.

The following method should not be employed for

pumps fitted with a ceramic rotor.

Pumps fitted with a metallic rotor (1999):

If necessary hit the edge of sleeve (5115) at an angle

with the help of a wooden block and a plastic ham-

mer. Taking care not to damage the O-rings (8060)!

■

■

■

■

■

GB

1999 10500085 A1998

5065

5440

1050,

1999

1050,

1999

5115 1050,

1999

8060

Loading...

Loading...