General ventilation connection

Ventilation installation must be carried out in accord-

ance with current norms and directives.

To prevent fan noise being transferred to the ventila-

tion devices, it may be a good idea to install a silencer

in the duct. This is especially important if there are

ventilation devices in noise sensitive rooms.

Connections must be made via flexible hoses, which

must be installed so that they are easy to replace. The

extract air duct must be provided with diffusion-tight

insulation (PE30) over its entire length. Ensure that the

condensation insulation is sealed at any joints and/or

at lead-in nipples, silencers, roof cowls or similar. Provi-

sion must be made for inspection and cleaning of the

duct. Make sure that there are no reductions of cross-

sectional area in the form of kinks, tight bends etc.,

since this will reduce the ventilation capacity. The air

duct system must be a minimum of air tightness class

B. The extract air duct must be a maximum of 20 m

long with a maximum of six bends.

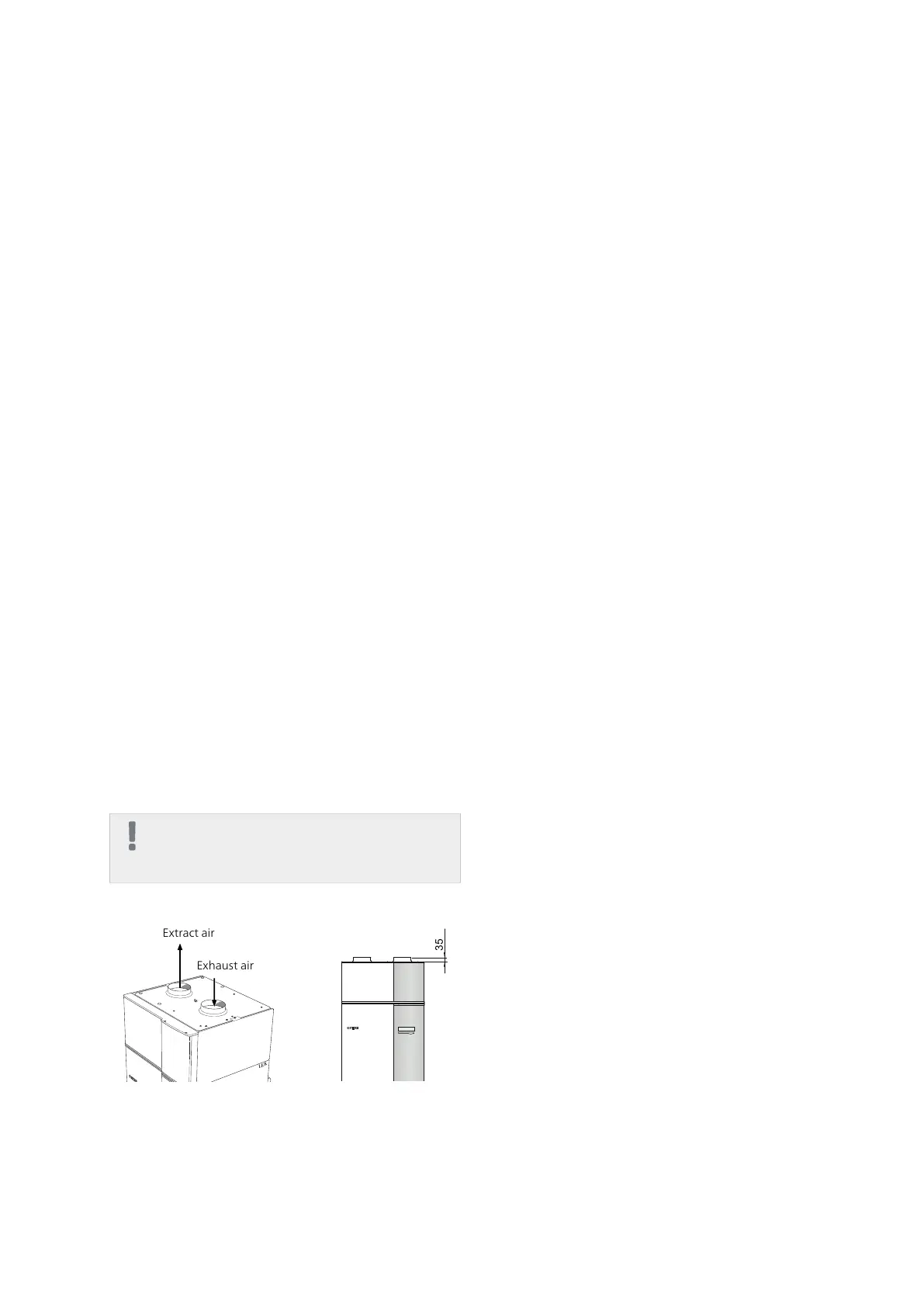

Because the heat pump contains the flammable refri-

gerant propane (R290), the air ducting system must be

grounded. This is done by making a good electrical

connection to the ground cables enclosed (2 x) to each

extract air and exhaust air ducts. The cables must then

be connected to the ground studs on top of the top

cover.

Exhaust air duct /kitchen fan

Exhaust air duct (kitchen fan) must not be connected

to F370.

To prevent food vapour being transferred to F370 the

distance between the kitchen fan and the exhaust air

device must be considered. The distance should not be

less than 1.5 m, but this can vary between different

installations.

Always use a kitchen fan when cooking.

NOTE

A duct in a masonry chimney stack must not

be used for extract air.

595

145

440

560 440

2075

25-50

615

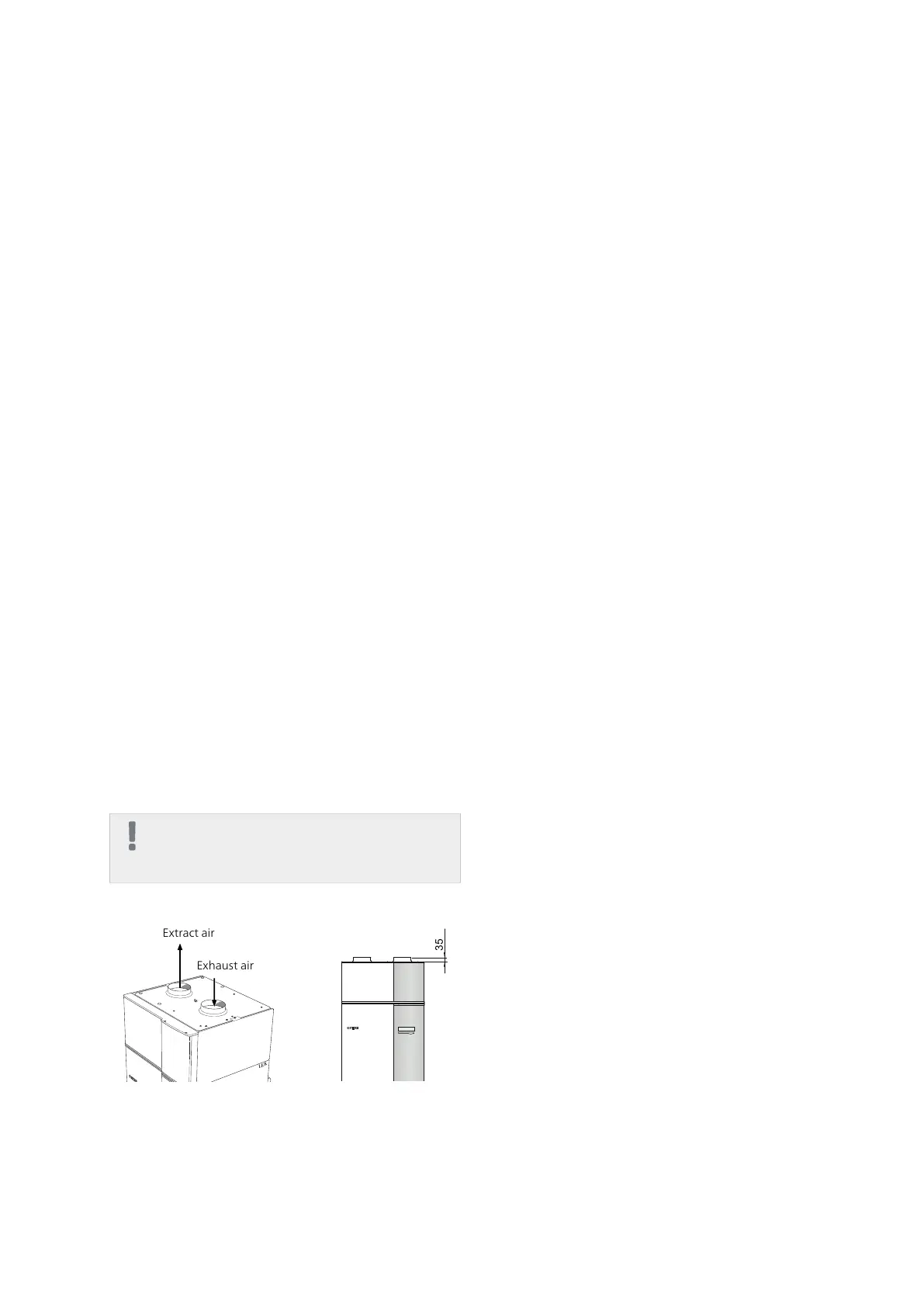

35

335

60

120

60

600

200

550

Undvik rördragning

inom markerat område

Ventilation flow

Connect F370 so that all exhaust air except exhaust air

duct air (kitchen fan) passes the evaporator (EP1) in

the heat pump. Lowest ventilation flow must fulfil ap-

plicable standards. For optimum heat pump operation

the ventilation flow must not fall below 28 l/s (100

m³/h) at an exhaust air temperature of at least 20 °C.

At times when the exhaust air temperature is below

20 °C (for example on start up and when there is no

one in the accommodation) the minimum value is 31

l/s (110 m³/h).

The heat pump’s installation area should be ventilated

by at least 5 l/s (18 m³/h). The installation area must

have a volume of at least 8 m³.

Ensure that the ventilation openings are not blocked.

Set the ventilation capacity in the heat pump's menu

system (menu 5.1.5).

Adjusting ventilation

To obtain the necessary air exchange in every room of

the house, the exhaust air devices must be correctly

positioned and adjusted and the fan in the heat pump

adjusted.

Immediately after installation adjust the ventilation so

that it is set according to the projected value of the

house.

A defective ventilation installation may lead to reduced

installation efficiency and thus poorer operating eco-

nomy, and may result in moisture damage to the house.

NIBE™ F370Chapter 4 | Pipe and ventilation connections18

Loading...

Loading...