Preparations

1.

Check that the switch (SF1) is in position " ".

2.

Check that the filling valves (QM10) and (QM11)

are fully closed.

Caution

Check the miniature circuit-breaker (FA1) in

the heat pump. It may have tripped during

transportation.

Filling and venting

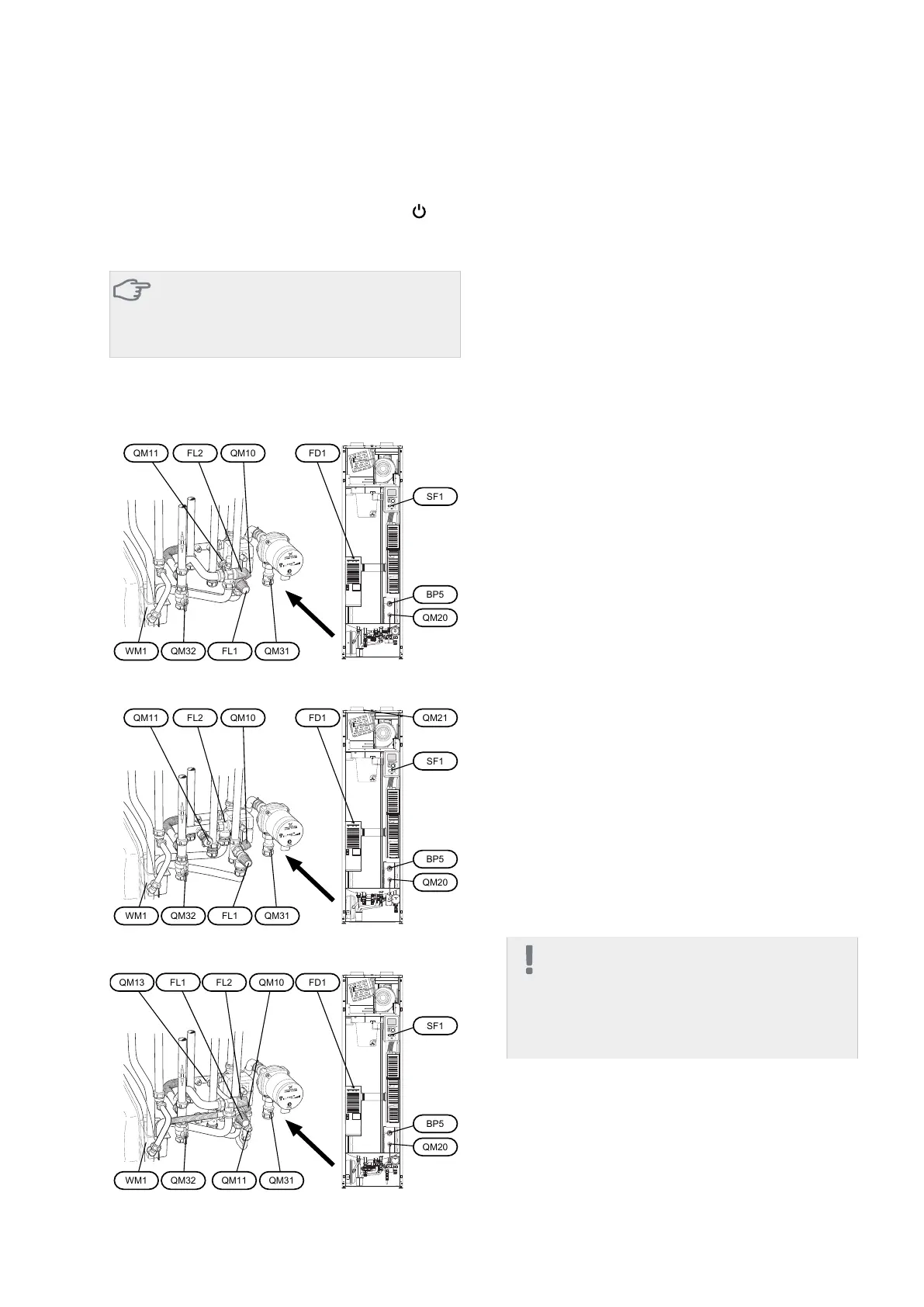

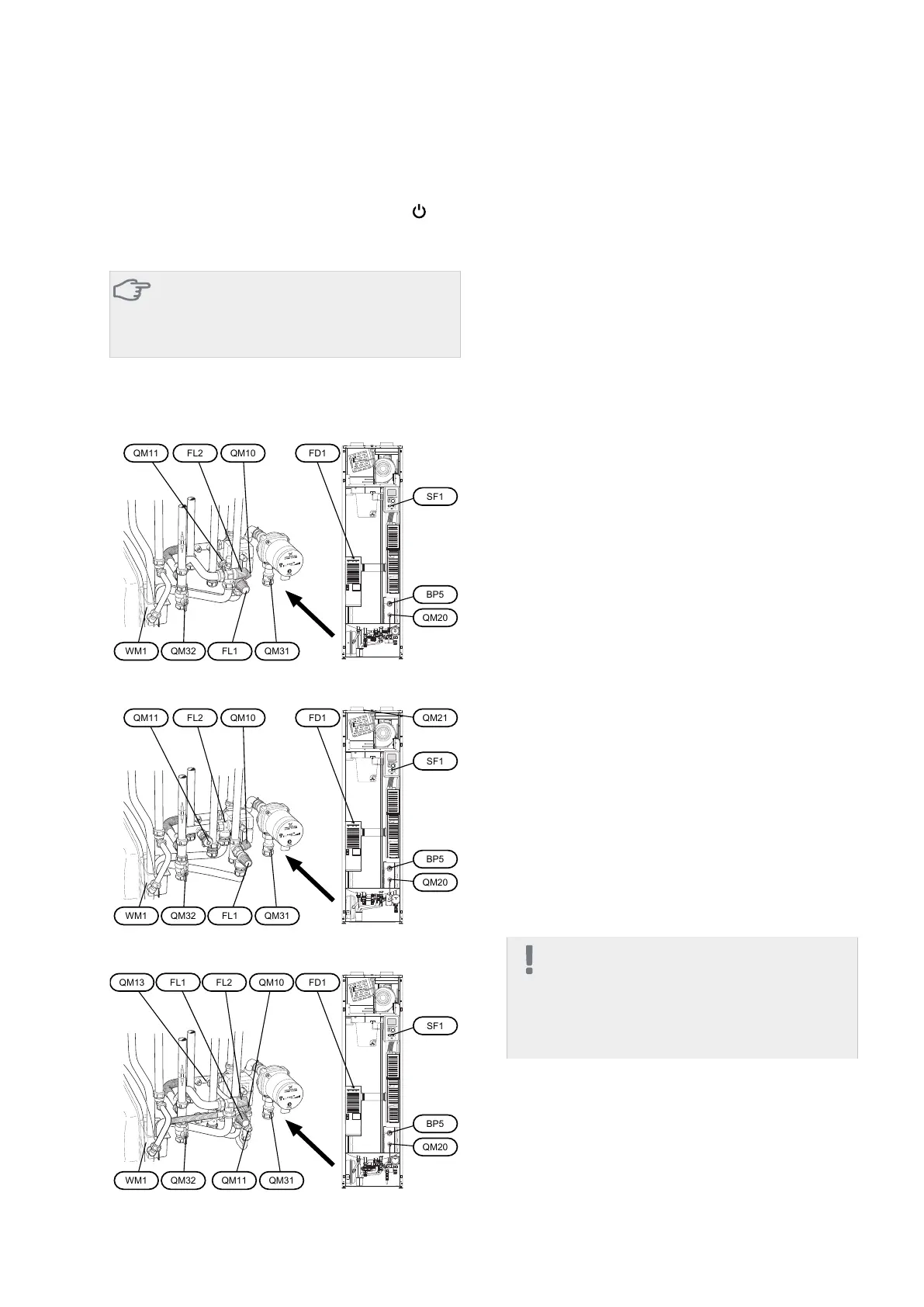

F370, copper

QM11

WM1 FL1

FL2 QM10

QM32 QM31

QM20

BP5

SF1

FD1

F370, enamel

WM1

QM10 QM21QM11

FL1

FL2

QM32 QM31

QM20

BP5

SF1

FD1

F370, stainless steel

WM1 QM11

QM20

BP5

FL1

QM10

SF1

FD1QM13

QM31QM32

FL2

Filling the hot water heater

1.

Open a hot water tap in the house.

2.

Open the filling valve (QM10). This valve should

then be fully open during operations.

3.

When water comes out of the hot water tap, the

hot water heater is full and the tap can be closed.

Filling the climate system

1.

Check that the shut off valves for the heating sys-

tem (QM31) and (QM32) are open.

2.

Open the venting valve (QM20).

3.

For F370, stainless steel: Check if the flexi hose

supplied is connected between connection (QM11)

and connection (QM13). Adjust the hose if this has

not been done.

4.

For F370, copper or enamel: Open the filling valve

(QM11). The boiler section and the rest of the cli-

mate system are filled with water.

For F370, stainless steel: Open the filler valves

(QM11), (QM13). The boiler unit and the rest of

the climate system are filled with water.

5.

When the water that exits the vent valve (QM20)

is not mixed with air, close the valve. After a while

the pressure rises on the pressure gauge (BP5).

When the pressure reaches 2.5 bar (0.25 MPa) the

safety valve (FL2) starts to release water. Close the

filler valve(s) (QM11) and (QM13).

6.

Reduce the boiler pressure to the normal working

range (approx. 1 bar) by opening the vent valve

(QM20) or safety valve (FL2).

7.

Check that there is water in the overflow cup

(WM1).

If the overflow cup requires topping up:

1.

Turn the safety valve (FL1) anticlockwise carefully.

Venting the climate system

1.

Turn off the power supply to the heat pump.

2.

Vent the heat pump via the vent valve (QM20) and

the rest of the climate system via the relevant vent

valves.

3.

Keep topping up and venting until all air has been

removed and the pressure is correct.

NOTE

The vent pipe from the container must be

drained of water before air can be released.

This means that the system is not necessarily

bled despite the flow of water when the bleed

valve (QM20) is opened.

NIBE™ F370Chapter 6 | Commissioning and adjusting30

6 Commissioning and adjusting

Loading...

Loading...