General information for the installer

For the Installer

12

Current regulations require the heating installation to

be inspected before it is commissioned. The inspec-

tion must be carried out by a suitably qualified person.

The above applies to installations with a closed

expansion vessel. A new inspection must be made

when changing the heat pump or the expansion ves-

sel.

The heat pump should preferably be erected with its

back about 10 mm from an outside wall in a utility

room or similar, to minimise noise nuisance. If this is

not possible, avoid placing it against a wall behind a

bedroom or other room where noise may be a prob-

lem. Irrespective of the placement the wall should be

sound insulated. NOTE! The distance between the

heat pump and the wall should be at least 10 mm. If

necessary, for example, with a low ceiling height, it is

possible to position the modules individually.

Route pipes so they are not fixed to an internal wall

that backs on to a bedroom or living room.

FIGHTER 600P has a venting screw located on the

front edge at the top. This should be easily accessible,

which should be considered during installation.

The heat pump should be transported and stored ver-

tically in the dry.

The heat pump contains highly inflam-

mable refrigerant. Special care should

be exercised during handling, installa-

tion, service, cleaning and scrapping to

avoid damage to the refrigerant system

and in doing so reduce the risk of leak-

age.

Transport and storage

Handling

Installation

Inspection of the installation

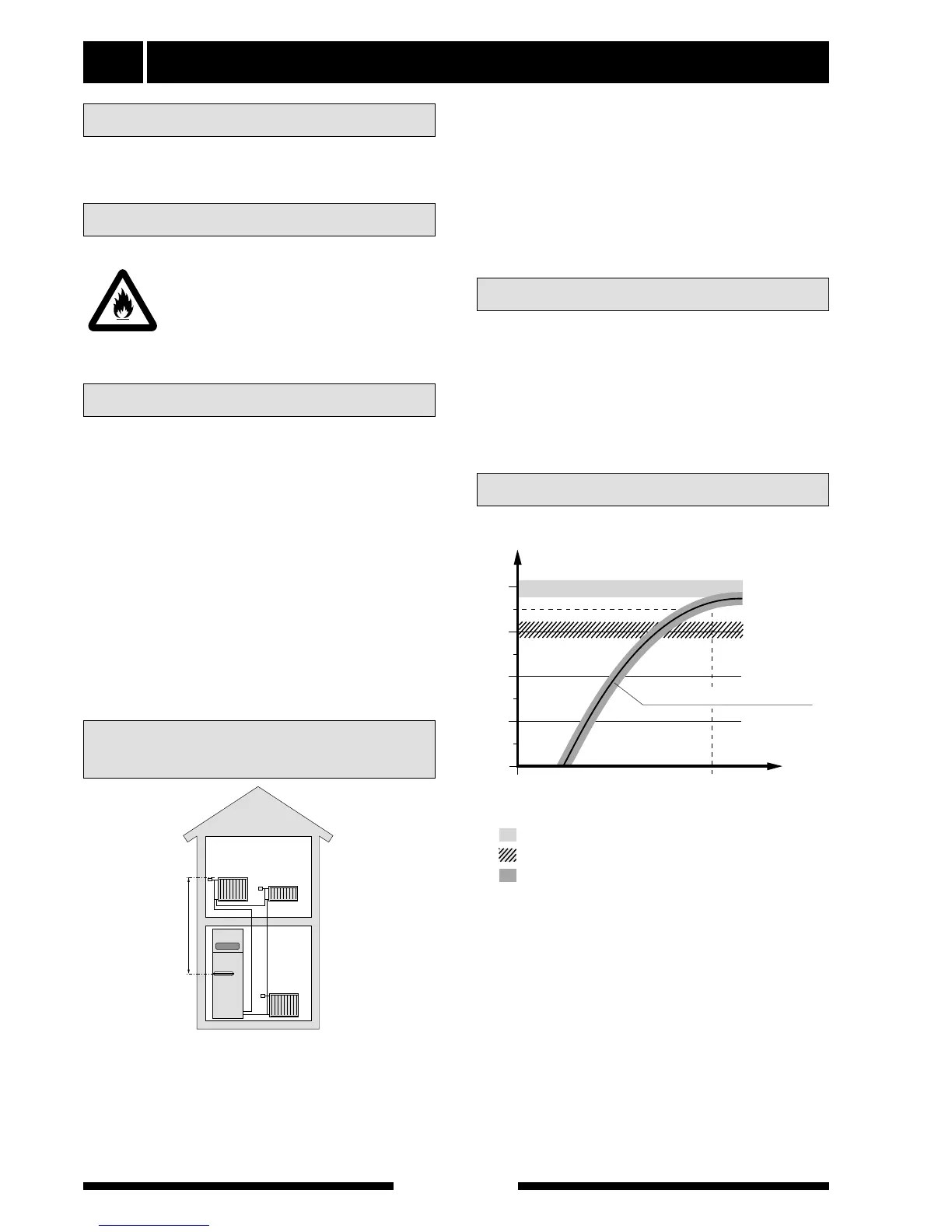

The volume of the expansion vessel (85) is 10 litres

and it is pressurised as standard to 0.5 bar (5 mvp).

As a result, the maximum permitted height “H”

between the vessel and the highest radiator is

5 metres; see figure.

If the standard initial pressure in the pressure vessel is

Maximum boiler and

radiator volumes

The Extra hot water knob (18) on the front panel is

used to increase the hot water capacity.

Temperatures in FIGHTER 600P

FIGHTER 600P

not high enough it can be increased by adding air via

the valve in the expansion vessel. The initial pressure

of the expansion vessel must be stated in the inspec-

tion document.

Any change in the initial pressure affects the ability of

the expansion vessel to handle the expansion of the

water.

The maximum system volume excluding the boiler is

217 litres at the above initial pressure.

Loading...

Loading...