Commissioning and adjusting18

The heating system is drained through the drain valve

(51). This is located behind the lower service cover.

The service cover is opened by loosening both

screws on the upper edge of the cover and then lift

the cover up/forward.

For the Installer

FIGHTER 600P

NOTE! As an option to the procedure set out below a

drying process can be used, see the Drying process

section.

■ Set the switch (8) to “”. In this mode the elec-

tronics are disconnected, so the display window is

not lit. The thermostat (3) opens at 71 °C in this

mode.

■ When the room temperature goes above 16 °C set

switch (8) to “1”. NOTE! The compressor has a

start delay of about 20 minutes.

■ Set the design capacity on the circulation pump

using its switch (35). See the section Pipe connec-

tions - Pump and pressure drop diagram. Make

sure that the switch is not in an intermediate posi-

tion.

■ Remove the upper service cover so the pressure

gauge (42) becomes visible

■ Connect a hose to the filling valve (49) and open

the valve to fill the boiler and the radiator system.

■ After a while the pressure gauge (42) will show ris-

ing pressure. When the pressure has reached

about 2.5 bar a mix of air and water starts to

emerge from the safety valve (52). Close the filling

valve (49).

Check that the switch (8) is set to “0”.

Check that valves (44) and (50) are fully open and that

the temperature limiter (6) has not tripped (press the

firmly on the rubber membrane).

Filling the heating system

Starting

Preparations

■ Vent the electric boiler through the safety valve

(52), venting screws (17), (59) and the rest of the

heating system through the relevant venting

valves.

■ Keep topping up and venting until all air has been

removed and the pressure is correct.

Venting the heating system

Air is initially released from the hot water and venting

may be necessary. If bubbling sounds can be heard

from the heat pump, the entire system requires further

venting. NOTE! Safety valve (52) also acts as a man-

ual venting valve. Operate it with care, since it opens

quickly. When the system is stable (correct pressure

and all air eliminated) the automatic heating control

system can be set as required. See the section Room

temperature - Setting the Automatic heating control

system and Front panel.

Readjustment

Draining the heating system

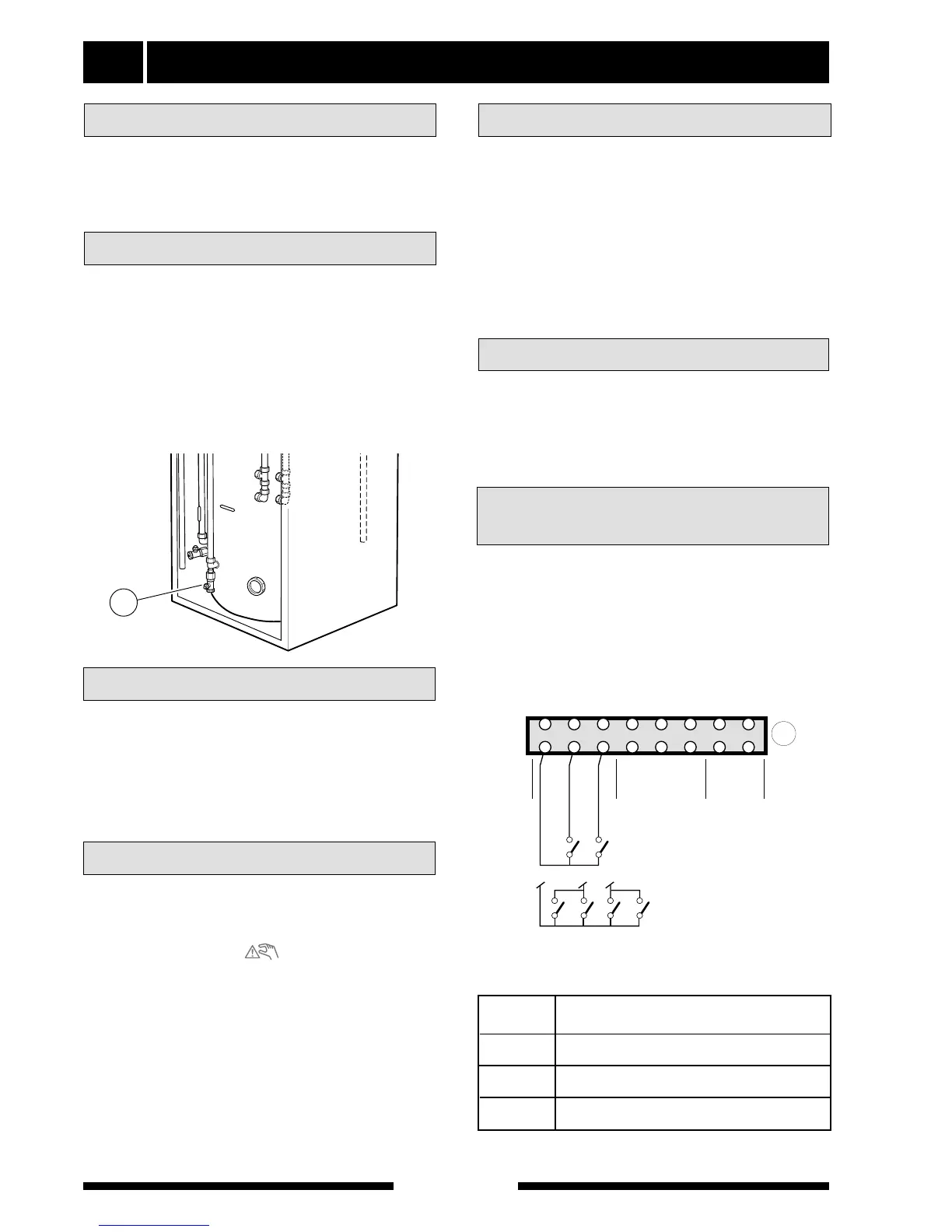

The output steps of the immersion heater can be dis-

connected by means of a load sensor or a centralised

load control relay. This is done with making contacts,

connected to terminal (14).

If both the load monitor and centralised load control

are to be used these are connected in parallel.

Centralised load control and

load monitor

Rundstyrning

eller effektvakt

14

123 4 5678

U-PUMPE PARALLEL +–––AB

SCHUTZKLEINSPANNUNG SELV

AB

FERNSTEUERUNGRUNDSTEUERUNG AUSSENFÜHLER

Rundstyrning (RS)

och effektvakt (BV)

RSBV RSBV

The table below describes output disabling:

External Disconnected output step

contact when the contact is made

5 and 6

(max electrical output 6 kW with standard connection)

4, 5, and 6

(max electrical output 3 kW with standard connection)

3, 4, 5 and 6

(no electrical output available)

A

B

A and B

Loading...

Loading...