Summary

Chapter 1 P. 5

Chapter 2 P. 7

Chapter 3 P. 12

Chapter 4 P. 15

Chapter 5 P. 21

Chapter 6 P. 29

Chapter 7 P. 31

Chapter 8 P. 42

AD700E

25

General information

Important safety information

General Information and Ratings

Mechanical Installation

Operation

Parameters

Analog and Digital Input Macro

Configurations

Power Wiring

Chapter 9 P. 48

Chapter 10 P. 50

Modbus RTU Communications

Technical Data

Trouble Shooting

Chapter 11 P. 54

PREVIOUS VIEW

5.7 MOTOR THERMAL OVERLOAD PROTECTION - 5.7.1 - 5.7.2 - 5.8

5

5.7 MOTOR THERMAL OVERLOAD PROTECTION

5.7.1 INTERNAL THERMAL OVERLOAD PROTECTION

The drive has an in-built motor thermal overload function; this is in the

form of an “I.t-trP” trip after delivering >100% of the value set in P-08 for

a sustained period of time (e.g. 150% for 60 seconds).

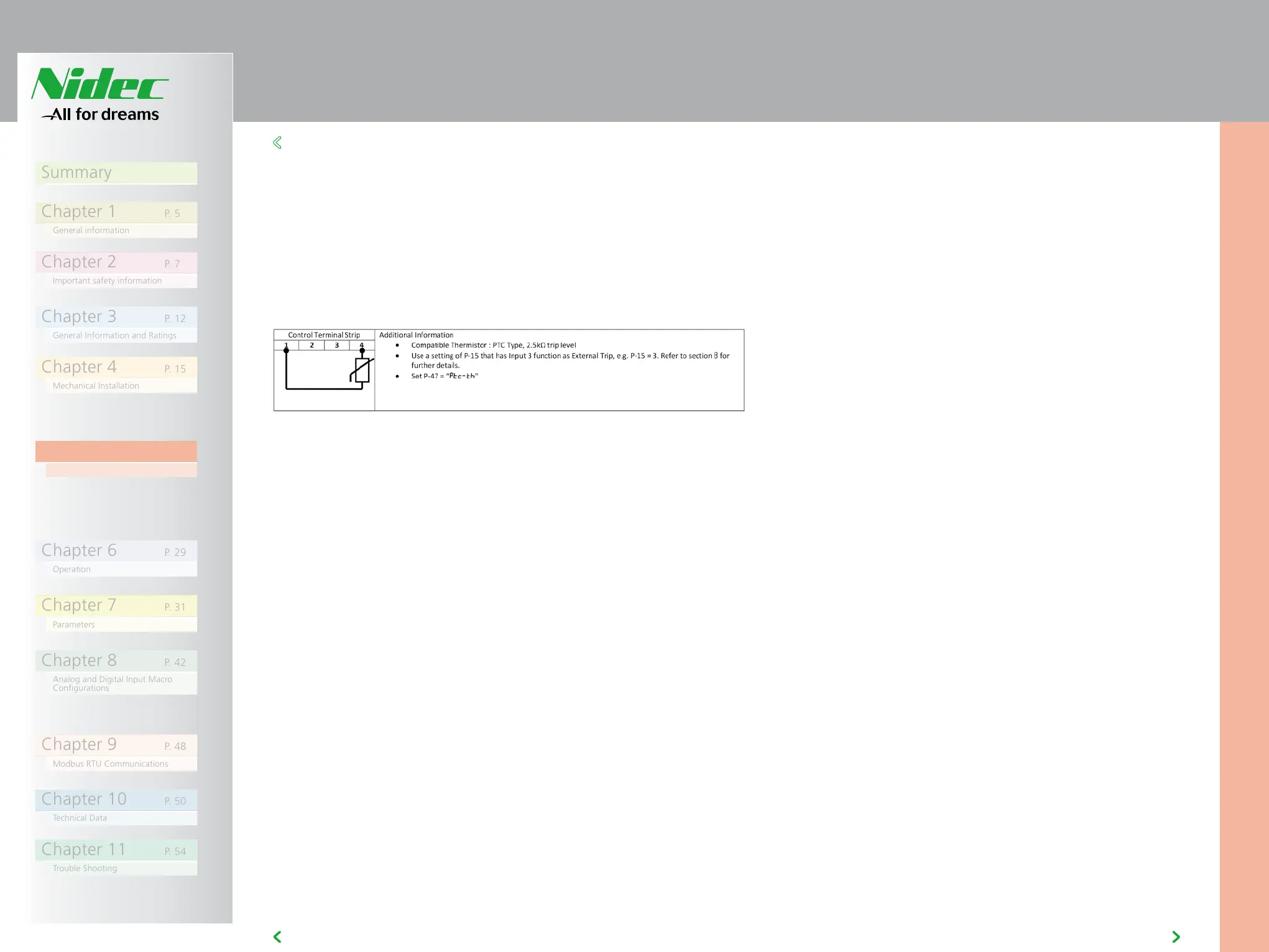

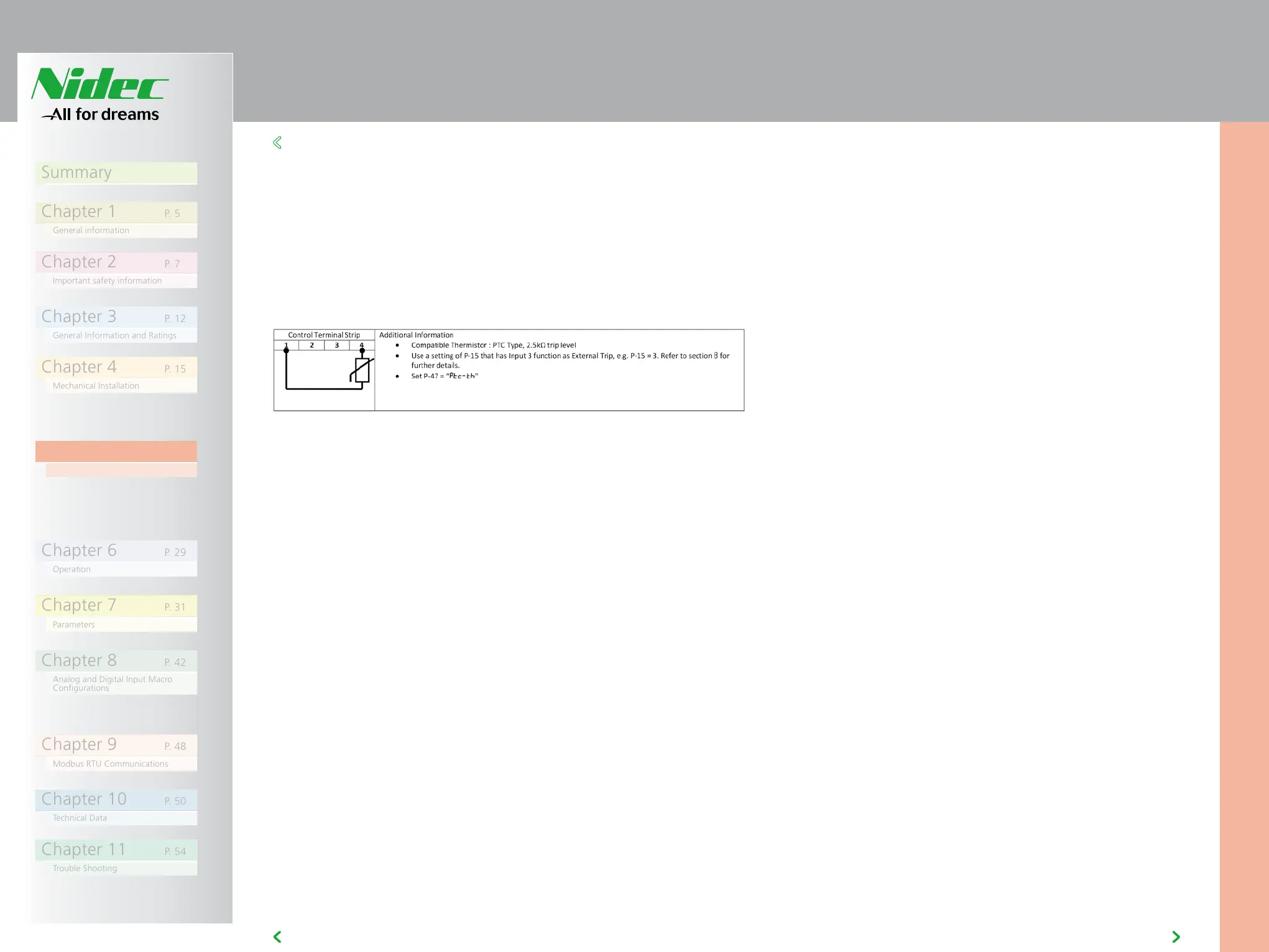

5.7.2 MOTOR THERMISTOR CONNECTION

Where a motor thermistor is to be used, it should be connected as follows:

5.8 CONTROL TERMINAL WIRING

• All analog signal cables should be suitably shielded. Twisted pair cables

are recommended.

• Power and Control Signal cables should be routed separately where

possible, and must not be routed parallel to each other.

• Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC,

should not be routed in the same cable.

• Maximum control terminal tightening torque is 0.5Nm.

• Control Cable entry conductor size: 0.05 – 2.5mm2 / 30 – 12 AWG.

Loading...

Loading...