Summary

Chapter 1 P. 5

Chapter 2 P. 7

Chapter 3 P. 12

Chapter 4 P. 15

Chapter 5 P. 21

Chapter 6 P. 29

Chapter 7 P. 31

Chapter 8 P. 42

AD700E

18

General information

Important safety information

General Information and Ratings

Mechanical Installation

Operation

Parameters

Analog and Digital Input Macro

Configurations

Power Wiring

Chapter 9 P. 48

Chapter 10 P. 50

Modbus RTU Communications

Technical Data

Trouble Shooting

Chapter 11 P. 54

PREVIOUS VIEW

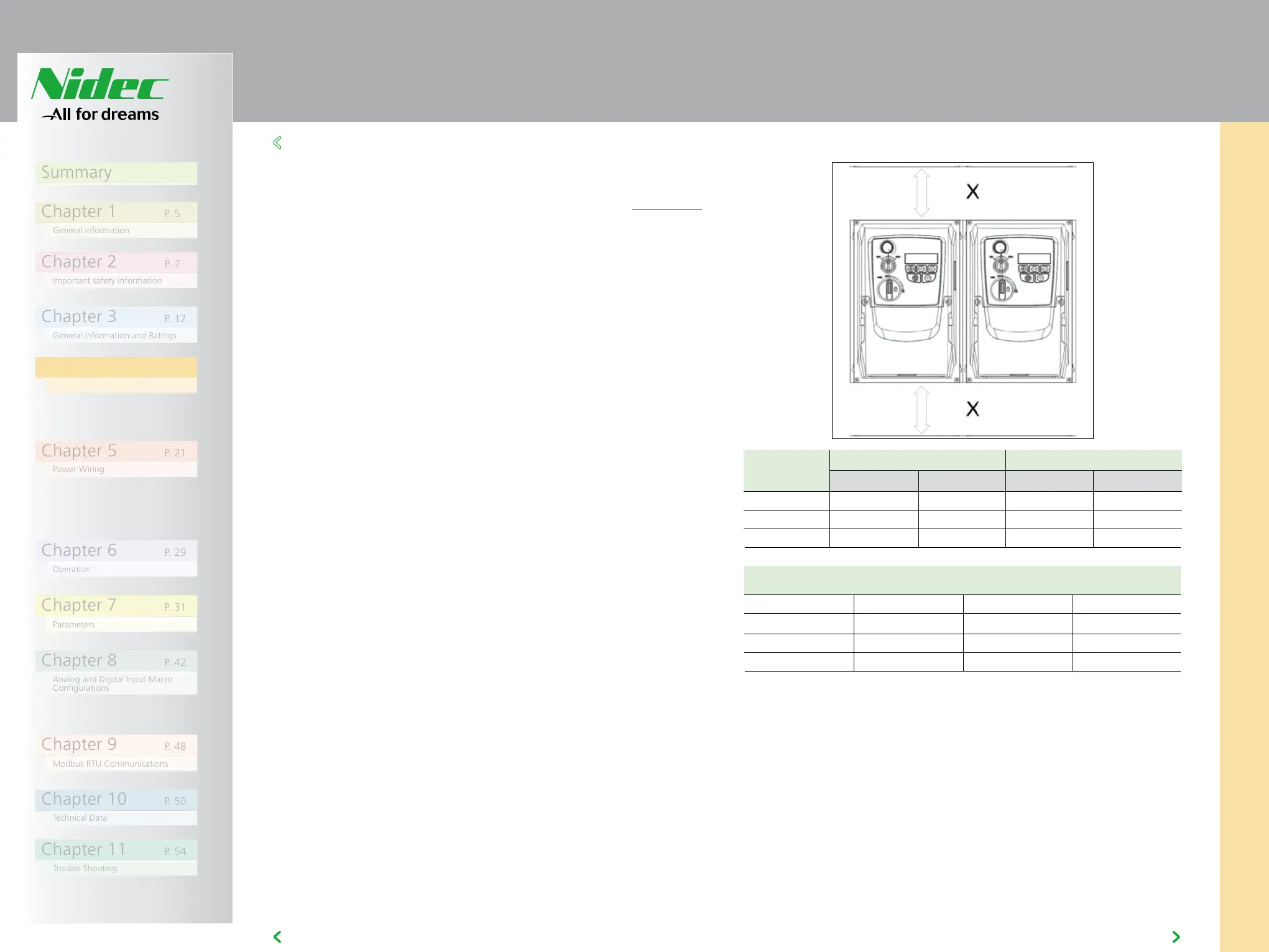

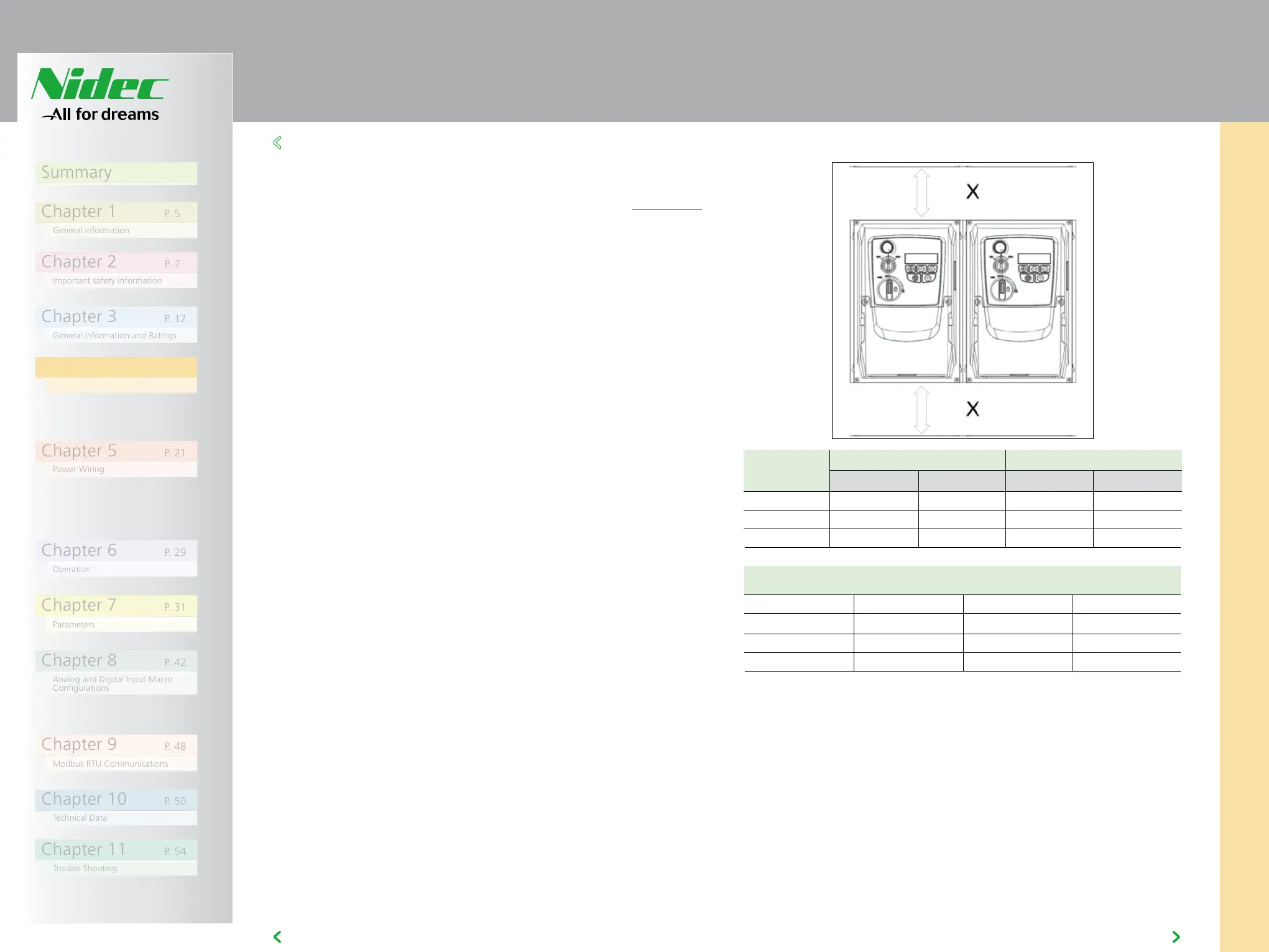

4.6 GUIDELINES FOR MOUNTING (IP66 UNITS)

4

4.6 GUIDELINES FOR MOUNTING (IP66 UNITS)

• Before mounting the drive, ensure that the chosen location meets the

environmental condition requirements for the drive shown in section 10.1

• The drive must be mounted vertically, on a suitable flat surface

• The minimum mounting clearances as shown in the table below must be

observed

• The mounting site and chosen mountings should be sufficient to support

the weight of the drives

• Using the drive as a template, or the dimensions shown above, mark the

locations required for drilling

• Suitable cable glands to maintain the ingress protection of the drive are

required. Gland holes for power and motor cables are pre-moulded into

the drive enclosure, recommended gland sizes are shown above. Gland

holes for control cables may be cut as required.

NOTE:

Typical drive heat losses are approximately 3% of operating load

conditions.

Above are guidelines only and the operating ambient temperature of the

drive MUST be maintained at all times.

Drive Size X Above & Below Y Either Side

mm in mm in

1 200 7.87 10 0.39

2 200 7.87 10 0.39

3 200 7.87 10 0.39

Cable Gland Sizes

Drive Size Power Cable Motor Cable Control Cables

1 M20 (PG13.5) M20 (PG13.5) M20 (PG13.5)

2 M25 (PG21) M25 (PG21) M20 (PG13.5)

3 M25 (PG21) M25 (PG21) M20 (PG13.5)

Loading...

Loading...