44015503TH Rev. 1

200 /

Oki Data CONFIDENTIAL

7. TROUBLESHOOTING PROCEDURE

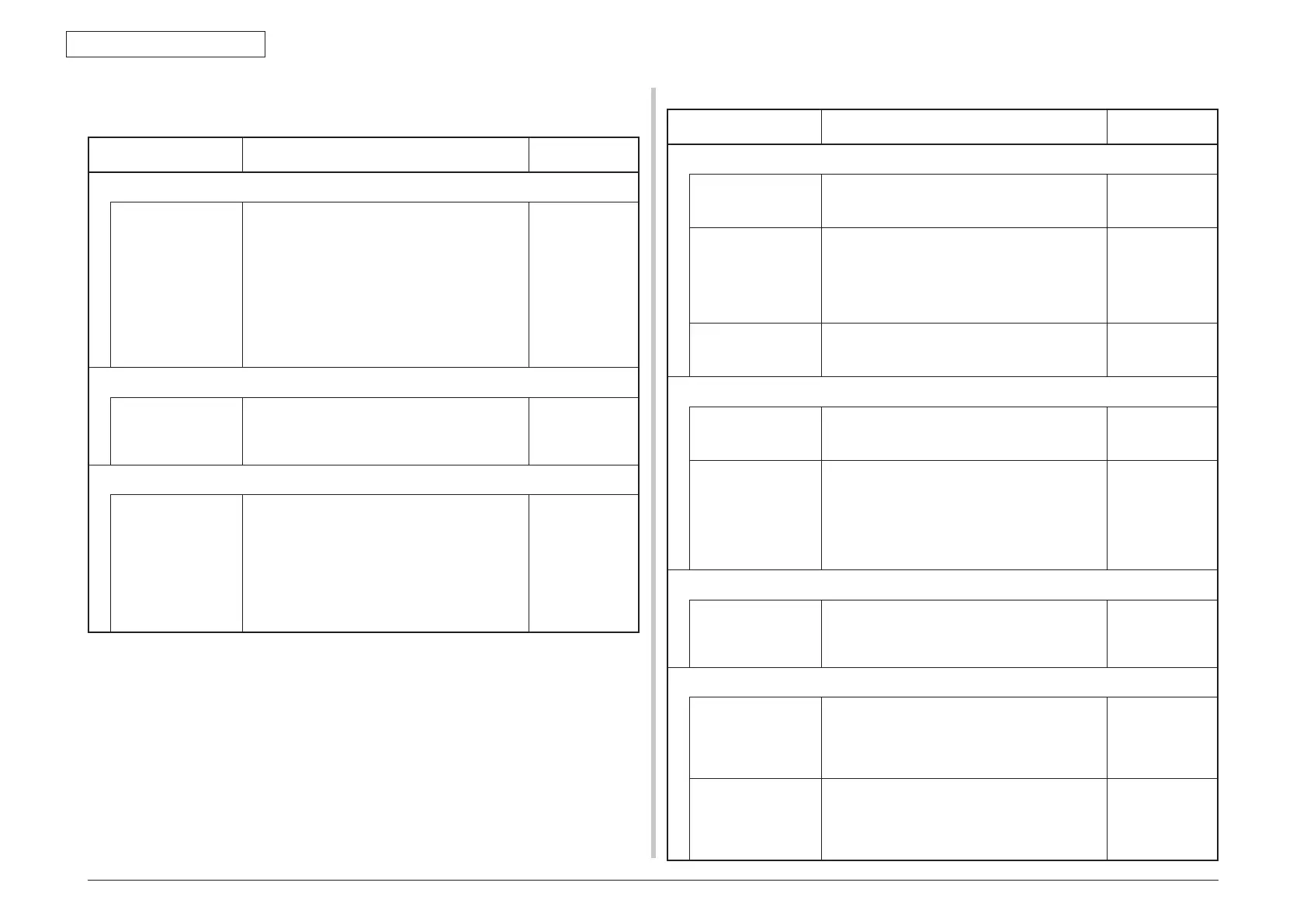

7.5.2.(8) Two-sided printing jam (error code: 370, 371, 372, 373, 383)

(8-1) Two-sided printing jam occurs immediately after the power is turned on.

Check item Check work

Action to be taken

at NG

(8-1-1) Check condition of the paper running path

Paper running path

of the Duplex unit

Chec

k if paper is jammed or not in the paper

running path.

Open the front cover and check if any paper

remains in the Duplex feeder or not.

Open the rear cover and check if any paper

remains in the paper reversing path or not.

Remove the Duplex unit. Check if any paper

exists in the Duplex insertion slot or not. Open

the cover of the Duplex paper running path and

check if any paper remains inside of the Duplex

unit.

Remove the

jammed paper.

(8-1-2) Check condition of the mechanical parts

Check the sensor

levers of the

respective sensors

of the Duple

x unit.

Check if shape and movement of the sensor

levers have any abnormality or not.

Replace the

sensor lever

with the good

sensor lever.

(8-1-3) Check condition of electrical parts

Check the detection

condition of the

sensor signal.

Confir

m that the sensor signals are normally

detected by using the SWITCH SCAN function

of the self-diagnostic mode.

For all sensors except the Dup-IN sensor, check

the detection condition of the respective sensor

in the two status: One is the status in which

paper remains inside the Duplex unit. The other

is the status in which paper is removed from the

Duplex unit.

Replace the

Duplex board

(V7Y PCB),

or replace the

defective sensor

or connection

cable.

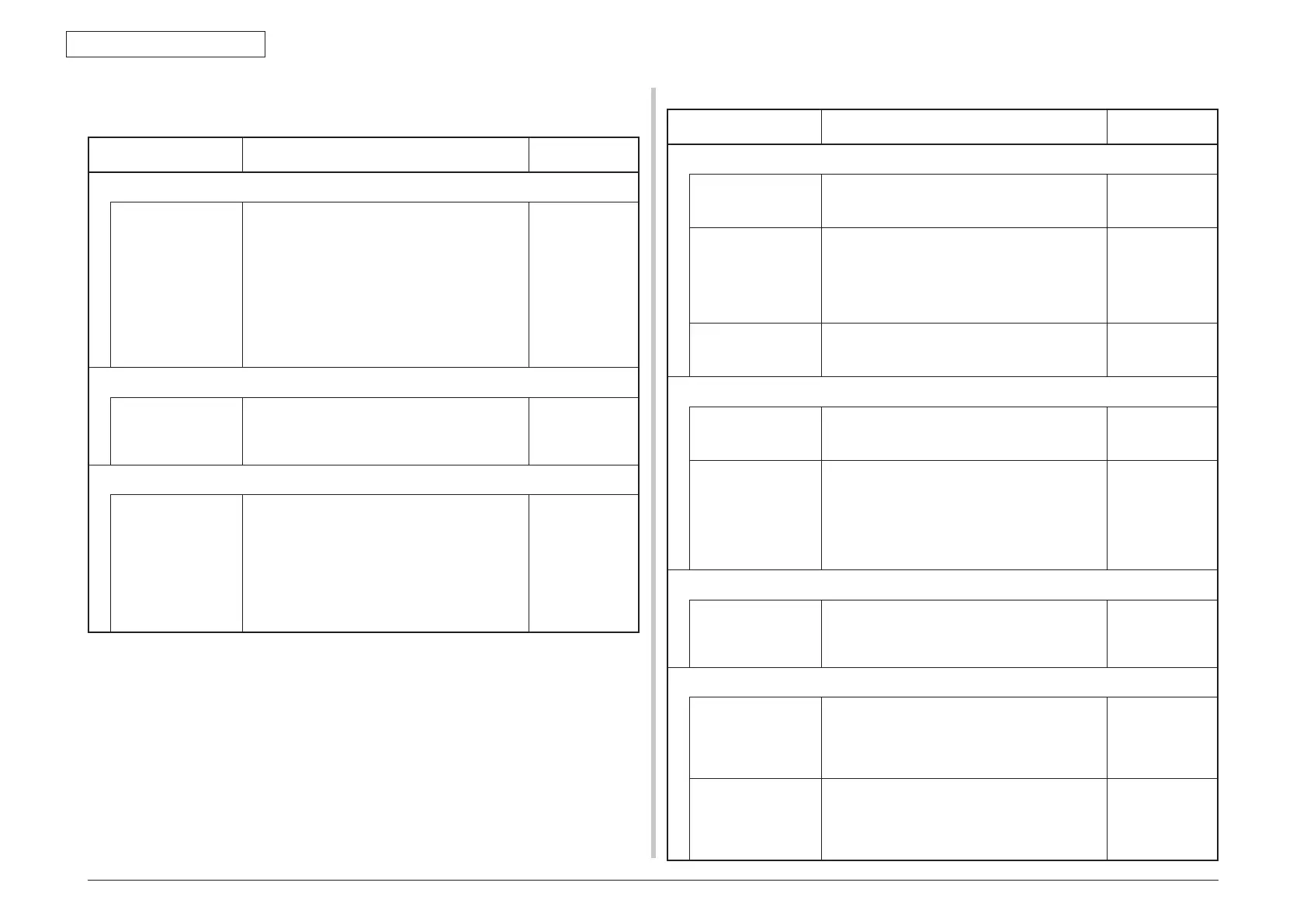

(8-2) Two-sided printing jam occurs during taking in the paper into Duplex unit.

Check item Check work

Action to be taken

at NG

(8-2-1) Solenoid operation check

Duplex solenoid Confirm that the Duplex solenoid works normally

by using the Motor & Clutch Test of the self-

diagnostic mode.

Replace the

V

7Y board or

solenoid.

Separator DUP

(Paper unloading/

DUP paper taking-

in switching gate

located immediately

after the fuser unit)

Check visually movement of the gate by using

the Motor & Clutch Test of the self-diagnostic

mode. (EXIT SOLENOID)

Check if movement is unsmooth or not, if

amount of open/close is abnormal or not.

Replace the

separator DUP.

ON/OFF timing of

the Duplex solenoid

While the cover is in the opened state, perform

the test print and confirm if the timing to open

the separator DUP is correct or not.

Replace the WR

sensor lever or

solenoid.

(8-2-2) Sensor lever operation check

Dup-IN sensor le

ver Open the rear cover. Touch the Dup-IN sensor

lever to check if its movement is unsmooth or

not.

Replace the

Dup-IN sensor

lever

DUP-IN sensor Confirm that the sensor signals are normally

detected by using the SWITCH SCAN function

of the self-diagnostic mode.

Replace the

Duplex board

(

V7Y PCB),

or replace the

defective sensor

or connection

cable.

(8-2-3) Check condition of the paper running path

Paper inverting

tr

ansport path

Check that any foreign materials such as

paper chip or blue do not exist that hampers

the smooth movement of paper in the paper

inverting transport path.

Remove the

foreign material.

(8-2-4) Motor operation check

Duple

x motor Confirm that the Duplex solenoid works normally

by using the Motor & Clutch Test of the self-

diagnostic mode.

Open the rear cover and check rotation of the

roller.

Replace the

V

7Y board or

motor.

Duplex pull-in/

reversing roller and

its pinch roller

Check if the pull-in/reversing roller of the Duplex

unit contacts or not with the pinch roller of the

cover side when the Duplex rear cover is closed.

(Does the pinch roller rotate when the roller is

rotating?)

Replace the

rear cover.

Loading...

Loading...