38

- Print Sample [Nozzle print]

When using neon ink, Ny and Np are displayed in place of Lc and Lm respectively.

1

51

101

151

201

251

1 2 3 4 5 6 7 8 9 10

1

51

101

151

201

251

1 2 3 4 5 6 7 8 9 10

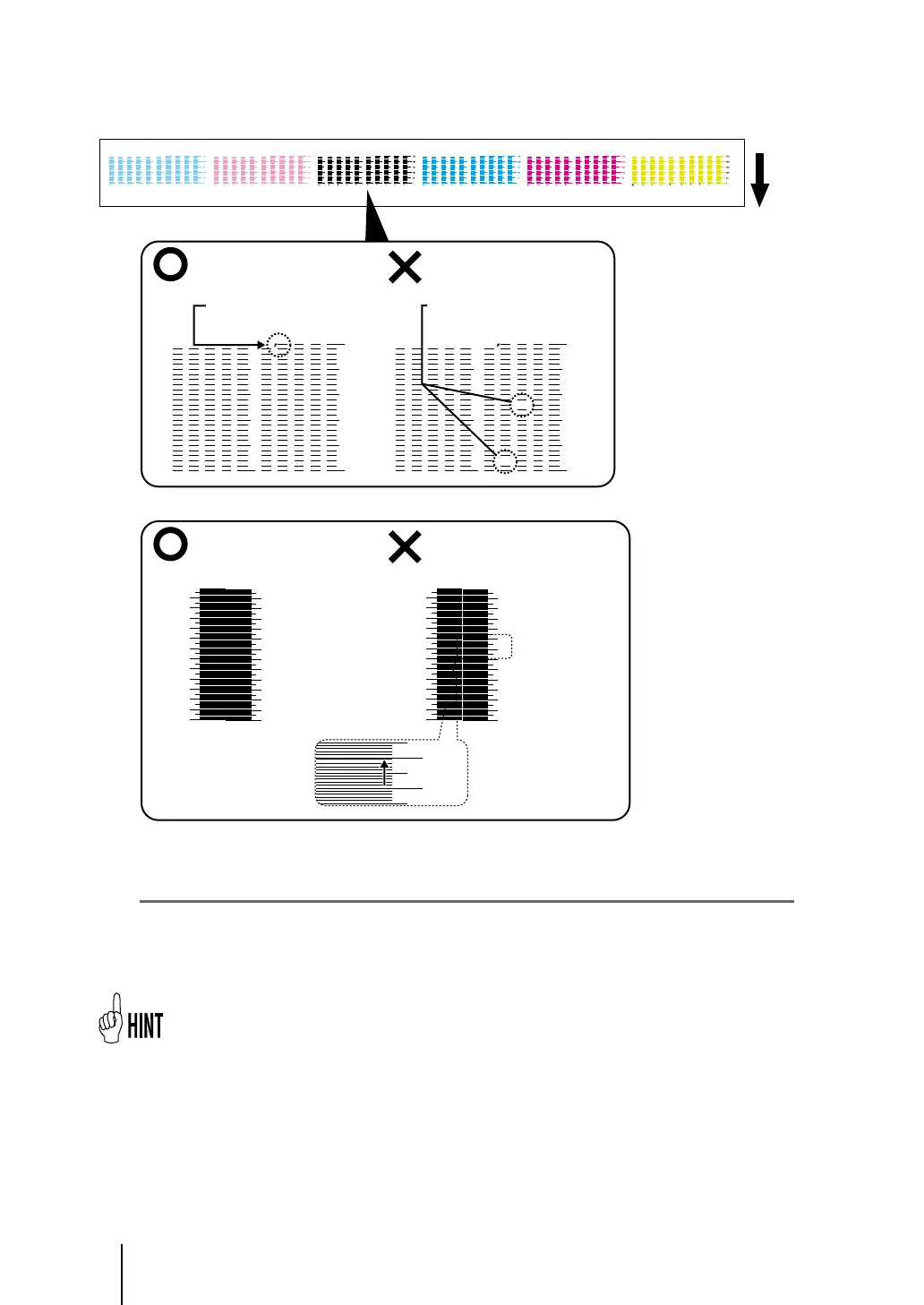

Missing lines are found

No line is missing and

the printout is correct

OK

NG

Mark for the last nozzle (nozzle 254)

Check that nozzle print is complete

up to the right of this mark.

Example when lines for nozzles 24

and 133 are missing in the printout.

Bent lines are found

No line is bent and the

printout is correct

OK

NG

1

21

41

61

81

101

121

141

161

181

201

221

241

2

22

42

62

82

102

122

142

162

182

202

222

242

1

21

41

61

81

101

121

141

161

181

201

221

241

2

22

42

62

82

102

122

142

162

182

202

222

242

The line printed by the nozzle 159

(indicated with the arrow) is bent to

the nozzle 161.

=> The nozzle 159 prints bent lines.

If the spaces between

the lines are even, no line

is bent.

If there are uneven

spaces between lines,

some lines may be bent.

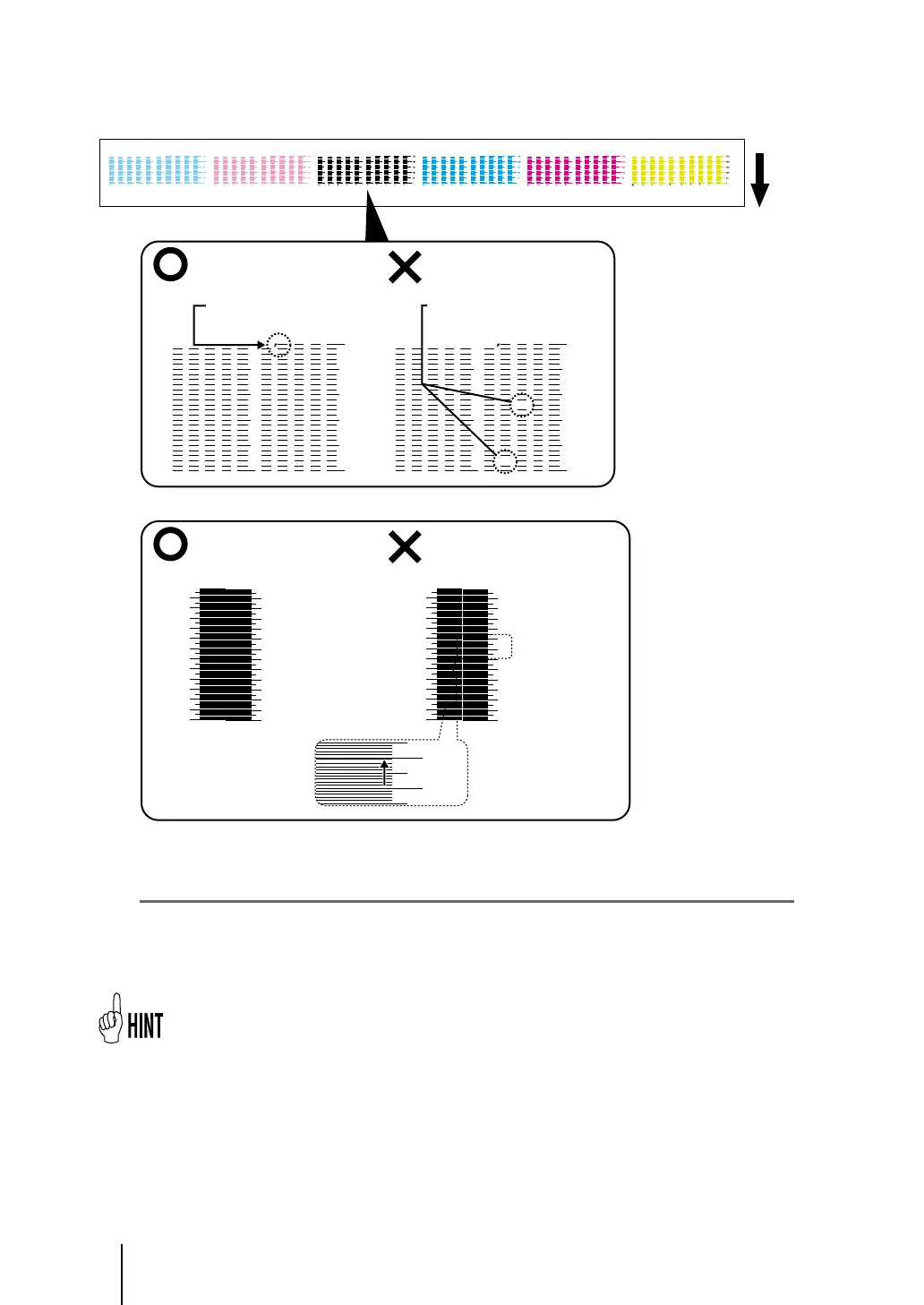

If pint defects are found on the nozzle print, perform (5) Print head cleaning [NORMAL] again. If print defects

still occur after several print head cleanings, perform settings for NOZZLE MAP

Note

- Do not expose the print heads for an unnecessarily long time when taking them out of the capping unit.

Finish the work quickly and cap the print heads.

Nozzle map (smart nozzle mapping) is a function used to prevent print quality degradation when an identied

nozzle is blocked. Generally, when only one nozzle is blocked, the print quality is not aected. However, when 2, 3

or more nozzles are blocked, the print quality is aected and the expected results may not be obtained. The smart

nozzle mapping function compensates the print defects due to a blocked nozzle by using another nozzle. Contact

a service representative is you are not able to compensate all print defects using this function.

Media advance direction

Loading...

Loading...