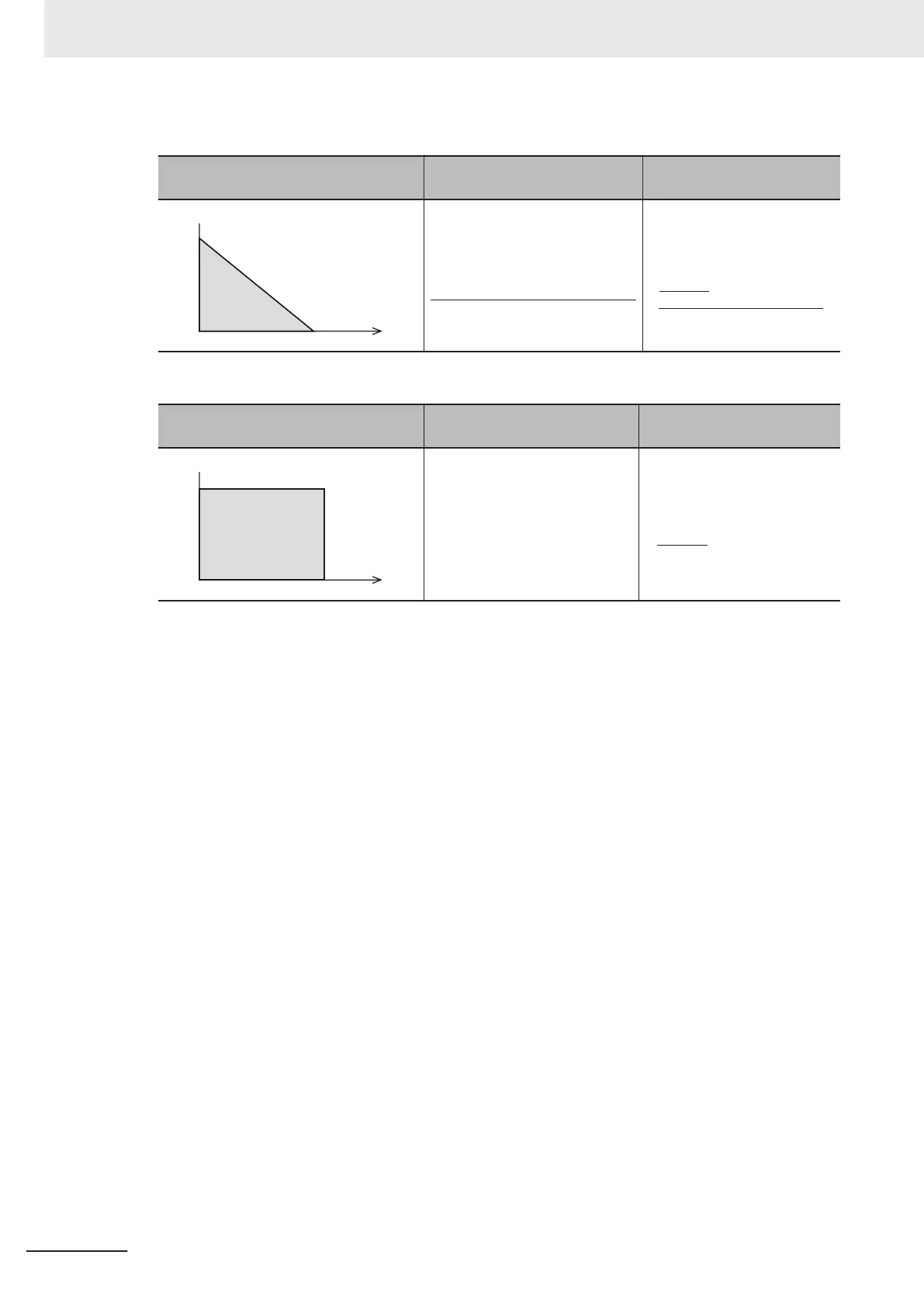

When braking load during deceleration decreases with time

How to apply a braking load Allowable average loss

Thermal braking resistance

value

Electronic Thermal for Braking

Resistor Discharging Capacity

(3004Hex-33Hex) =

Braking time (s) × Motor capacity (kW)

2

Electronic Thermal for Braking

Resistor Allowable Avera

ge

Loss (3004Hex-34Hex) =

× Motor capacity (kW)

2

%ED(%)

*1

100

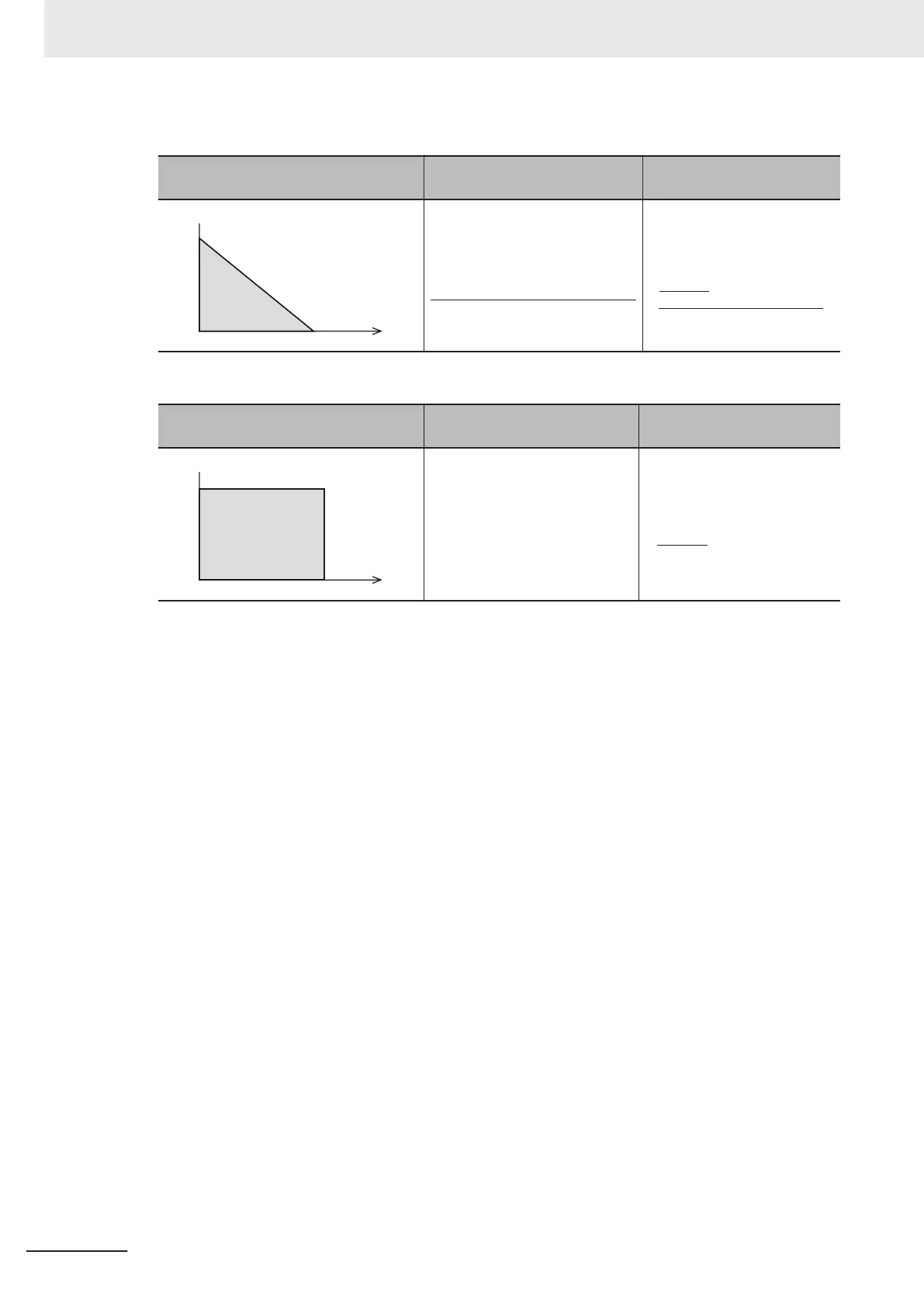

When braking load at deceleration is a constant speed

How to apply a braking load Allowable average loss

Thermal braking resistance

value

Braking time (s) × Motor capacity (kW)

Electronic Thermal for

Braking

Resistor Discharging Capacity

(3004Hex-33Hex) =

× Motor capacity (kW)

%ED(%)

*

1

100

Electronic Thermal for Braking

Resistor Allowable Average

Loss (3004Hex-34Hex) =

*1. %ED indicates the usage rate. It is the percentage of the time under braking in the interval where the

brake is applied. (Reference: A-10-3 Overview of Braking Resistor Selection on page

A-299)

• When a braking resistor capable of outputting a temperature detection signal is applied, allocate

“9: EXT (external trip)” to one of input terminals [DI1] to [DI7], and connect the temperature de-

tection signal of the braking resistor.

•

Even if there is actually little temperature rise, the electronic thermal sometimes is activated and

the overheating protection (alarm code: 16 hex) is generated depending on the braking resistor

specifications. Check the specifications of the braking resistor and set its parameter.

6 Basic Settings

6-68

M1 Series EtherCAT Type User’s Manual (I670)

Loading...

Loading...