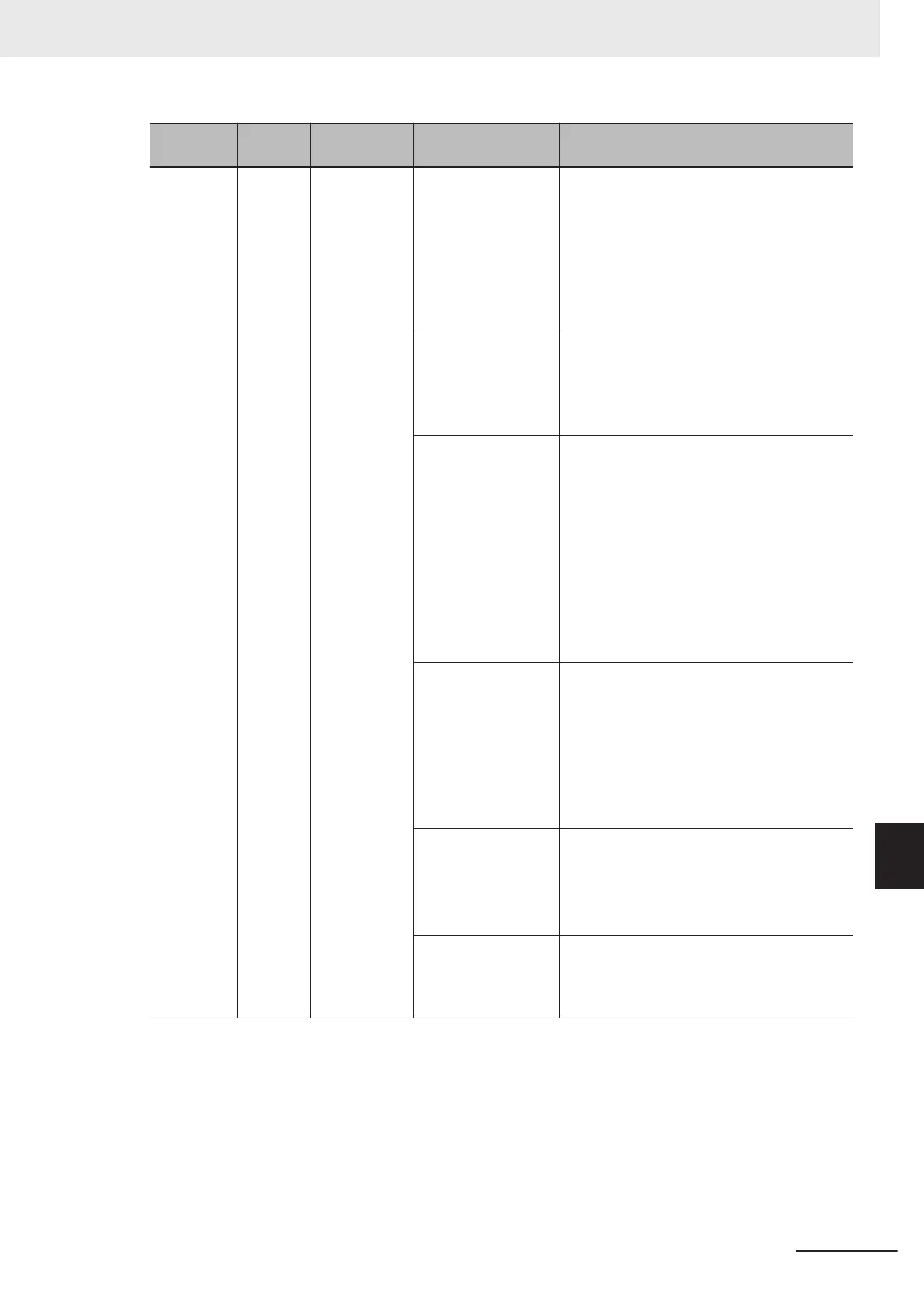

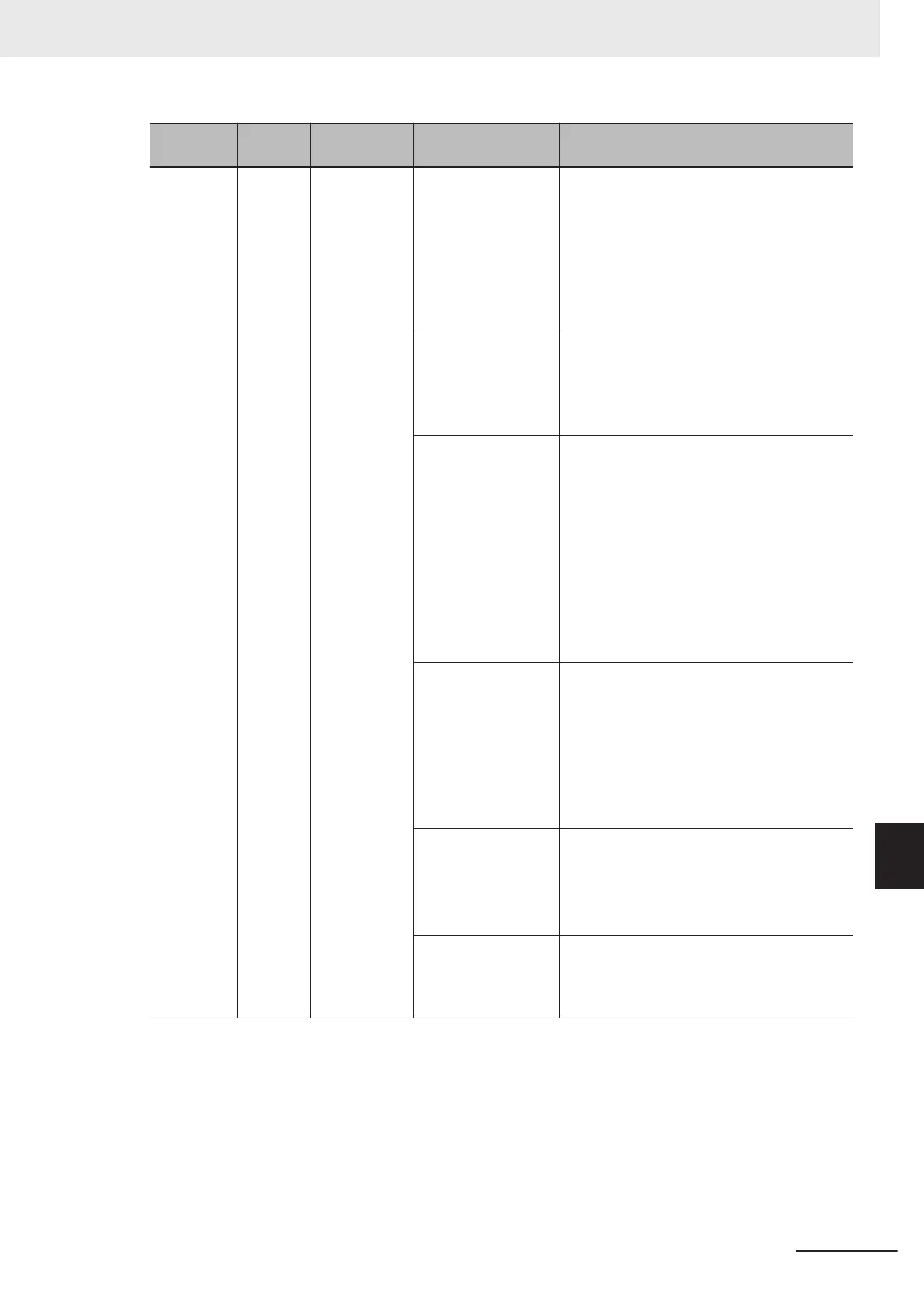

Alarm

code

Alarm

subcode

Name Description Check point and remedy reference

2A Hex

(Erd)

Stall detec-

tion/startup

magnetic pole

position de-

tection failure

(1) Different motor

characteristics

Check that object 3004Hex-05Hex,

3004Hex-06Hex, 3007Hex-02Hex,

3007Hex-03Hex, 3007Hex-04Hex,

3007Hex-3DHex, 3007Hex-3EHex,

3007Hex-3FHex, 3007Hex-40Hex,

3007Hex-41Hex data matches motor con-

stants.

→ Perform auto tuning.

(2) Magnetic pole po-

sition detection meth-

od is not appropriate

Check that the magnetic pole position detec-

tion method matches the motor type.

→ Match the magnetic pole position detec-

tion method (object 3007Hex-1FHex)

selection to the motor type.

(3) Insufficient start-

ing frequency (hold-

ing time) (object

3004Hex-19Hex)

Check that, when setting the magnetic pole

position detection method selection (object

3007Hex-1FHex*) to 0 or 3, the starting fre-

quency (holding time) (object

3004Hex-19Hex) is set optimally

.

→

Set a time that enables the motor to ro-

tate one revolution or more.

3004Hex-19Hex ≥ 3007Hex-02Hex/

2/3004Hex-18Hex (3007Hex-02Hex:

pole, 3004Hex-18Hex: starting frequen-

cy)

(4) Insufficient start-

ing torque

Check acceleration time (object

3004Hex-08Hex, 3005Hex-0BHex,

3005Hex-0DHex, 3005Hex-0FHex) and ref-

erence current at starting (object

3007Hex-4BHex) data.

→ Set an acceleration time that matches

the load.

→ Raise the reference current at starting.

(5) Low braking load Check reference current at starting (object

3007Hex-4BHex*) data.

→ Lower the reference current at starting.

When a motor is run on its own, such as

during a test run, set to 80% or lower

.

(6) The connection

between the inverter

and the motor is

missing phases

→

Ensure a correct connection between

the inverter and motor.

9 Troubleshooting

9-9

M1 Series EtherCAT Type User’s Manual (I670)

9-1 Alarm Display and Remedies

9

9-1-2 Alarm Code List

Loading...

Loading...