A

Appendix

A-4 CP1L Programming Examples

170 SYSMAC CP1L/CP1E Introduction Manual

4. Close the PLC Settings dialog box.

■Programming Example

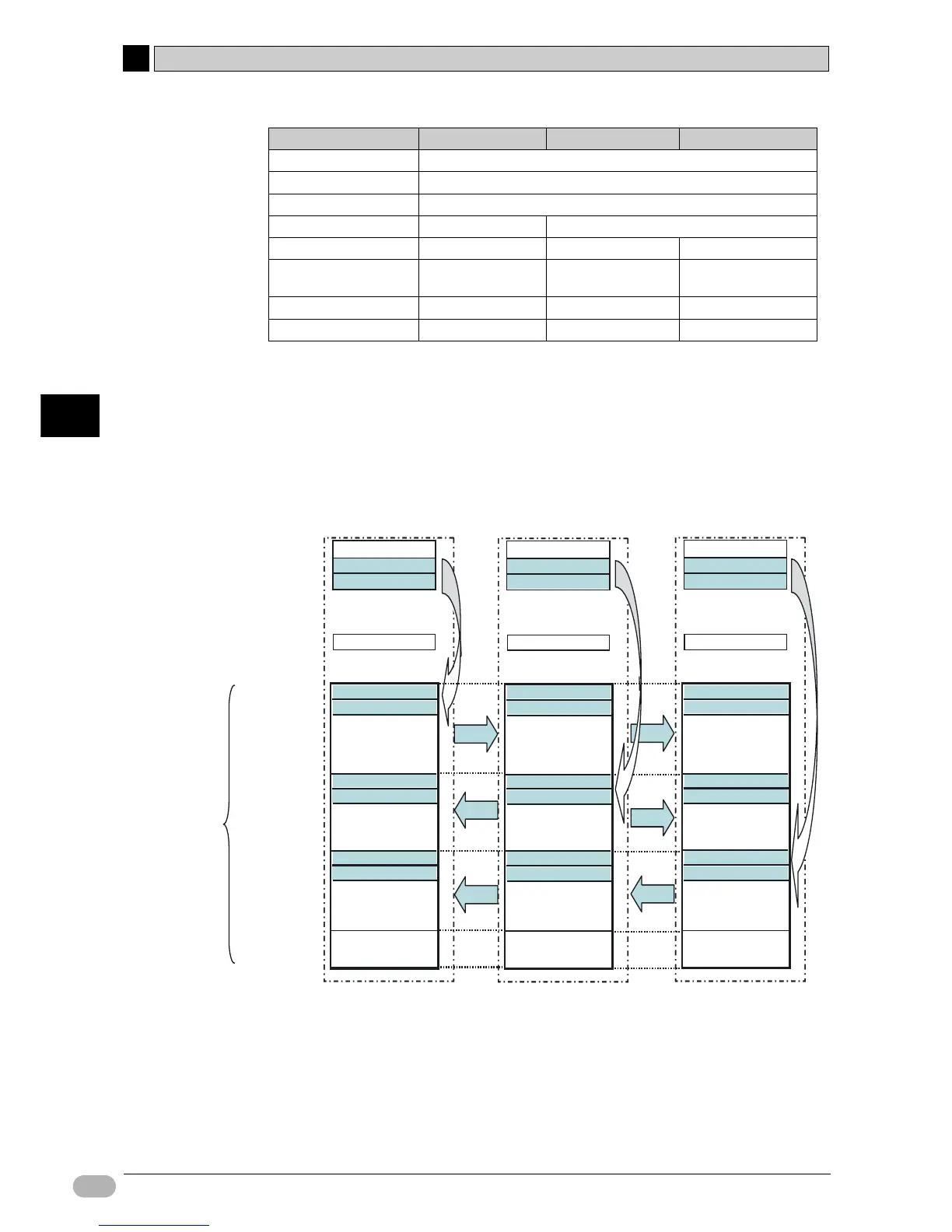

Serial PLC links are used for program-free linking of data in the serial PLC link

areas. The ladder program transfers the data to be linked to the data link area.

Note The values of CP1E are included in the paretheses.

Item Boiler A (Master) Boiler B (Slave No.0) Boiler C (Slave No.1)

Communication Settings Custom

Baud 115200bps

Format 7.2.E (Default)

Mode PLC Link (Master) PLC Link (Slave)

Link Words 10 (Default) - -

PLC Link Mode Complete Link

Method

--

NT/PLC Link Max 1 - -

PLC Link Unit No. - 0 1

Boiler A

CP1L (Master)

A_Temperature data 0

3100CH(200CH)

3101CH(201CH)

3109CH(209CH)

3110CH(210CH)

3111CH(211CH)

3119CH(219CH)

3120CH(220CH)

3121CH(221CH)

3129CH(229CH)

Serial PLC

link area

Input area

3189CH(289CH)

0CH

1CH

2CH

100CH

A_Temperature data 1

Output area

A_Temperature data 0

A_Temperature data 1

B_Temperature data 0

B_Temperature data 1

C_Temperature data 0

C_Temperature data 1

C_Temperature data 0

Input area

C_Temperature data 1

Output area

A_Temperature data 0

A_Temperature data 1

B_Temperature data 0

B_Temperature data 1

C_Temperature data 0

C_Temperature data 1

B_Temperature data 0

Input area

B_Temperature data 1

Output area

A_Temperature data 0

A_Temperature data 1

B_Temperature data 0

B_Temperature data 1

C_Temperature data 0

C_Temperature data 1

Boiler B

CP1L (Slave No.0)

Boiler C

CP1L (Slave No.1)

Loading...

Loading...