1 - 19

1 Overview

NX-series Safety Control Unit User’s Manual (Z930)

1-5 Commissioning Procedures

1

1-5-2 Detailed Procedures

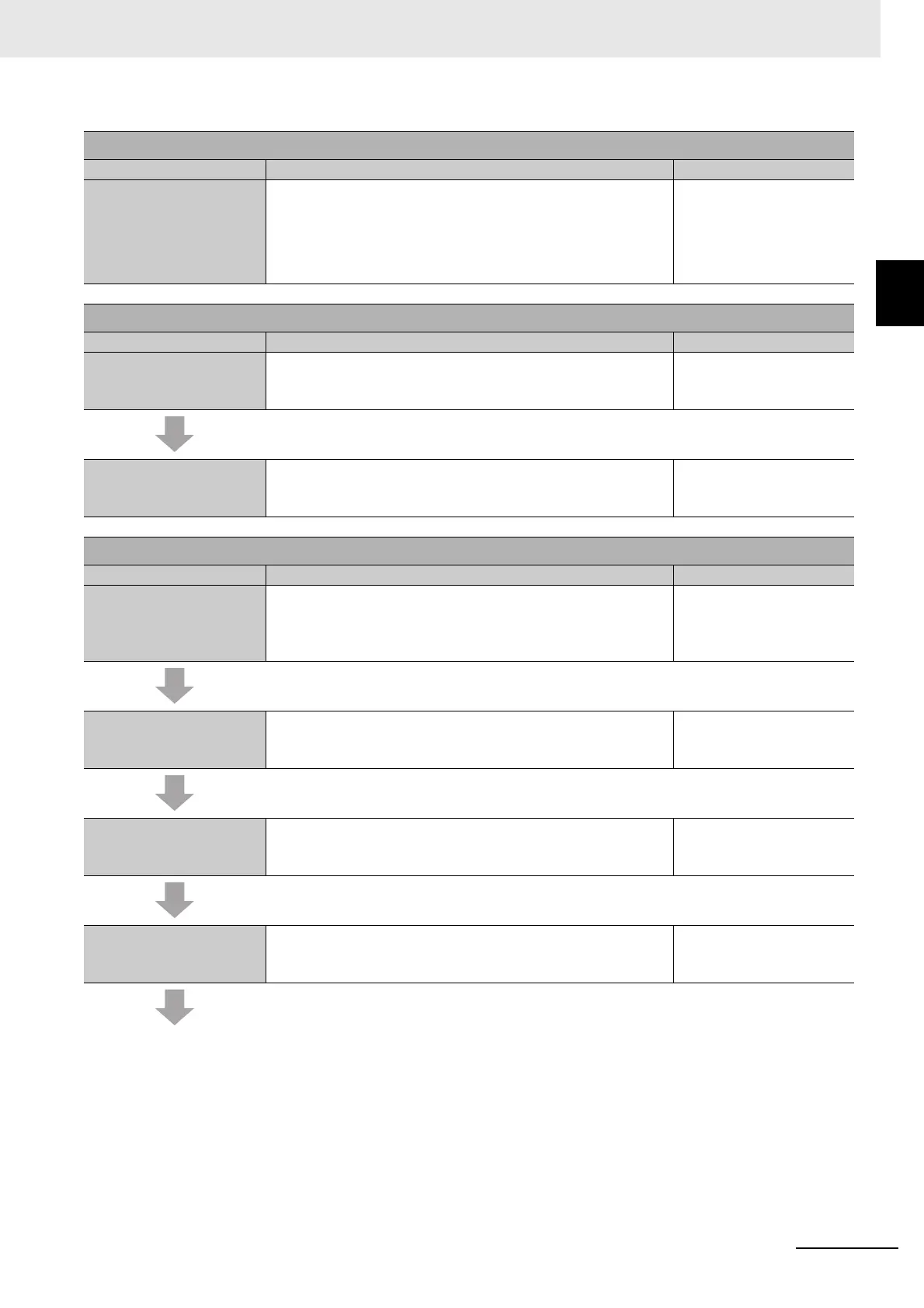

Step 2. Hardware Design

Step Description Reference

Step 2-1 Determining Wir-

ing for Communications,

Power Supply, and Exter-

nal I/O Devices

Determine the wiring for the communications network, power

supply, and safety I/O devices.

Section 3 Part Names and

Functions

Manuals for specific Com-

munications Coupler Units

NX Unit User’s Manuals

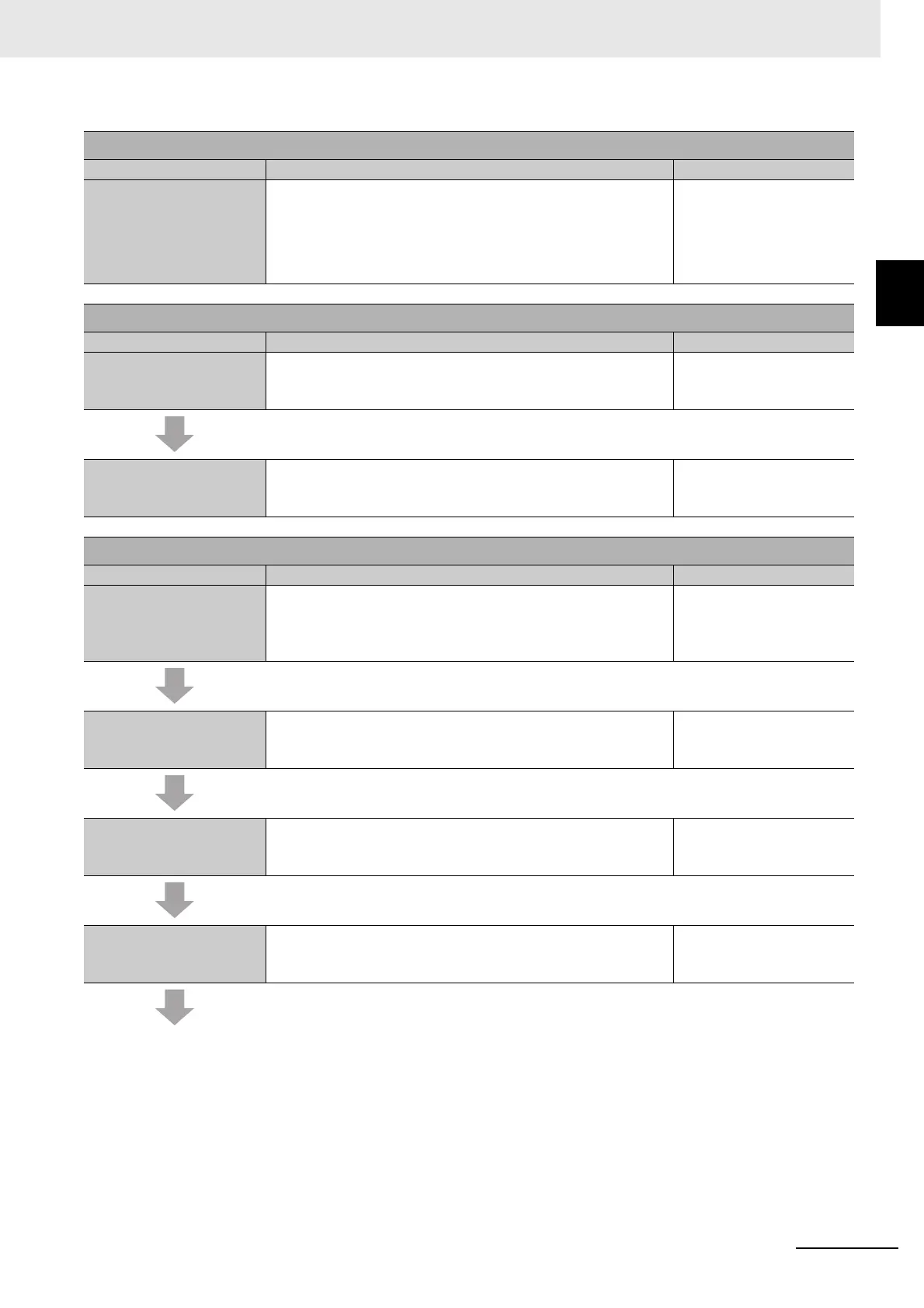

Step 3. Calculating and Verifying Safety Response Performance

Step Description Reference

Step 3-1 Calculating Safety

Reaction Time and Safety

Distance

Calculate the safety reaction times and use them to find the

safety distances.

Section 4 Calculating

Safety Reaction Times

Step 3-2 Verifying Fulfill-

ment of Required Specifi-

cations

Check to see if requirements are met. If requirements are not

met, reconsider the designs again starting with the system

design.

Section 4 Calculating

Safety Reaction Times

Step 4. Software Settings and Programming

Step Description Reference

Step 4-1 Creating the

Safety Control System

Configuration

On the Sysmac Studio, configure the Communications Coupler

Units, Safety CPU Units, and Safety I/O Units.

6-3 Controller Configura-

tion and Setup of the

Safety Control Units on

page 6-4

Step 4-2 Setting Up and

Checking the Safety Pro-

cess Data Communications

Check the settings for the safety process data communications

and make any necessary changes.

6-4 Setting Up the Safety

Process Data Communica-

tions on page 6-10

Step 4-3 Assigning Safety

I/O Terminals to the Con-

nected Devices

On the parameter setting tab page for the Safety I/O Units,

select the safety I/O devices that are connected to the safety I/O

terminals.

6-5 Setting the Safety Input

and Output Functions on

page 6-12

Step 4-4 Assigning Device

Variables to I/O Ports

Register the device variables in the global variable table. (You

can use either user-defined or automatically assigned variable

names.)

6-6 Registering Device

Variables on page 6-15

Loading...

Loading...