BATTERY

JUMP

STARTING

Occasionally,

it

may

be

necessary

to

jump

start (charge)

a

weak battery using

a

charged booster battery

to

start

your engine.

If

jump starting is necessary, the following

procedure

is

recommended in order to prevent starter

damage, battery damage and personal injuries.

-1

Overcranking the engine can cause

starter damage. Allow

5

minutes for

starter to cool

if

engaged for longer than

30

seconds.

1

L

TO BATTERY

1

I

Disconnect engine load,

2.

Use only a battery of the same voltage

(12V)

as is

used with your engine.

3.

Attach one end of the positive booster cable(red) to

the positive

(+)

terminal of the booster battery.

Attach the other end

of

the positive cable to the

positive

(+)

terminal of your engine battery.

Attach one end of the negative

(-)

booster cable

(black) to negative

(-)

terminal of booster battery.

Attach other end

of

negative cable to a solid chassis

ground on your engine.

-1

Electrical arcing can cause per-

sonalinjury.

Do

not allowpositive

and negative cable ends to touch.

Jump starting in any other manner may result in

damage to the battery or the electrical system.

Turn ignition switch to

ON

to start engine.

AWARN~NG

Jump starting a battery incor-

a

rectly can cause battery to

explode,

resulting

in

severe personal injury

or

death.

Do

not smoke or allow

any

ignition source

near the battery, and

do

not jump start a frozen

battery.

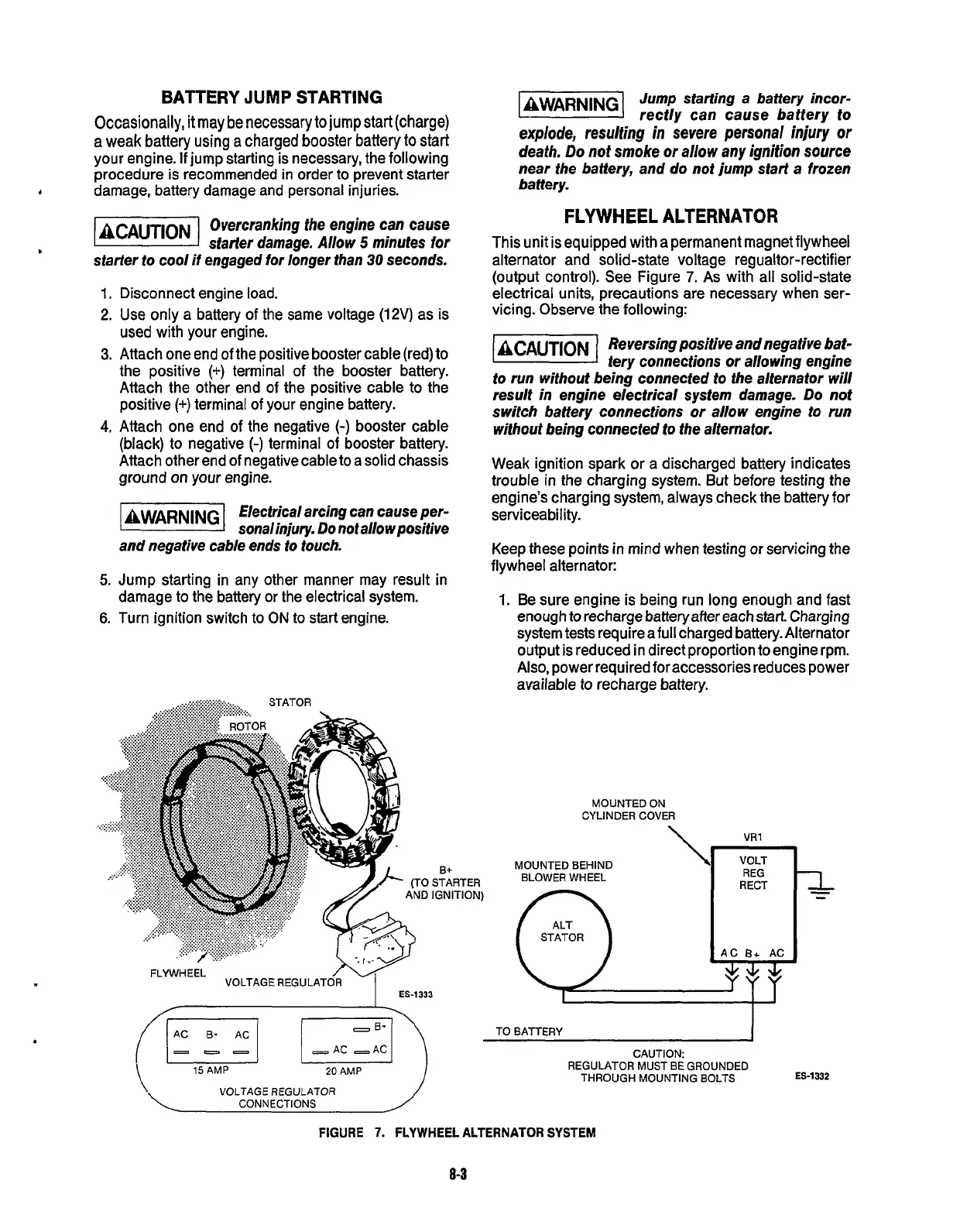

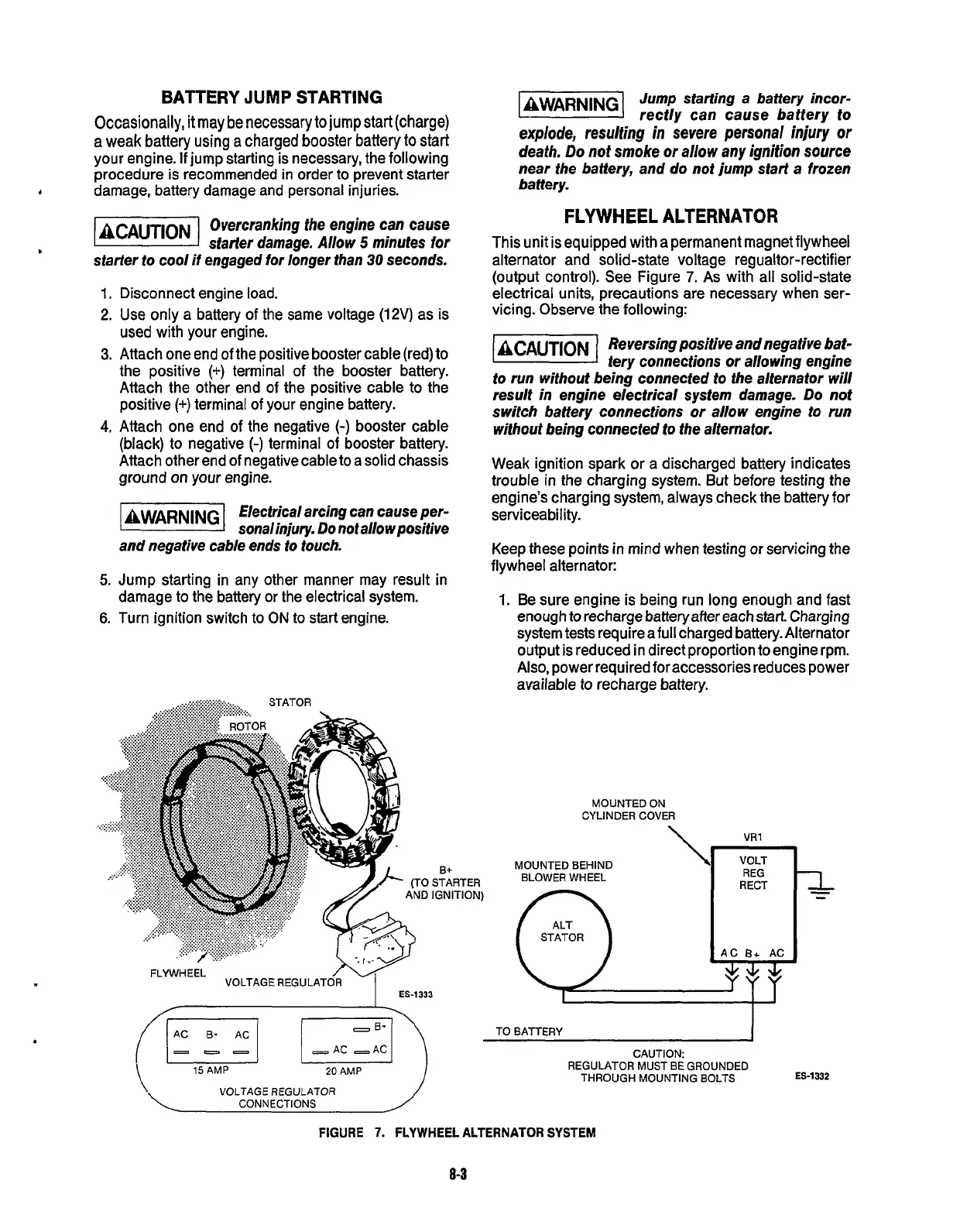

FLYWHEEL

ALTERNATOR

This unit is equipped with

a

permanent magnet flywheel

alternator and solid-state voltage regualtor-rectifier

(output control). See Figure

7.

As

with all solid-state

electrical units, precautions are necessary when ser-

vicing. Observe the following:

ACAUT~ON

Reversing positive and negative bat-

I

tery connections or allowing engine

to run without being connected to the alternator will

result

in

engine electrical system damage.

Do

not

switch battery connections or allow engine to run

without being connected

to

the alternator.

Weak ignition spark or a discharged battery indicates

trouble in the charging system. But before testing the

engine's charging system, always check the battery for

serviceability.

Keep these points in mind when testing or servicing the

flywheel alternator:

1.

Be sure engine is being run long enough and fast

enough to recharge batteryafter each start. Charging

system tests require afull charged battery. Alternator

output is reduced in direct proportion to engine rpm.

Also,

power required for accessories reduces power

available to recharge battery.

8-3

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...