Commutator Inspection:

If

commutator

is

dirty or dis-

colored, clean with number

00

to

000

commutator

paper,

Blow grit out of armature after

cleaning.

If

commutator is scored, rough, or worn, turn it down in a

lathe.

Inertia type starter inspection

Housing Inspection:

Permanent magnets are glued to

inside

of

the housing. Magnets must be secure and free

of cracks.

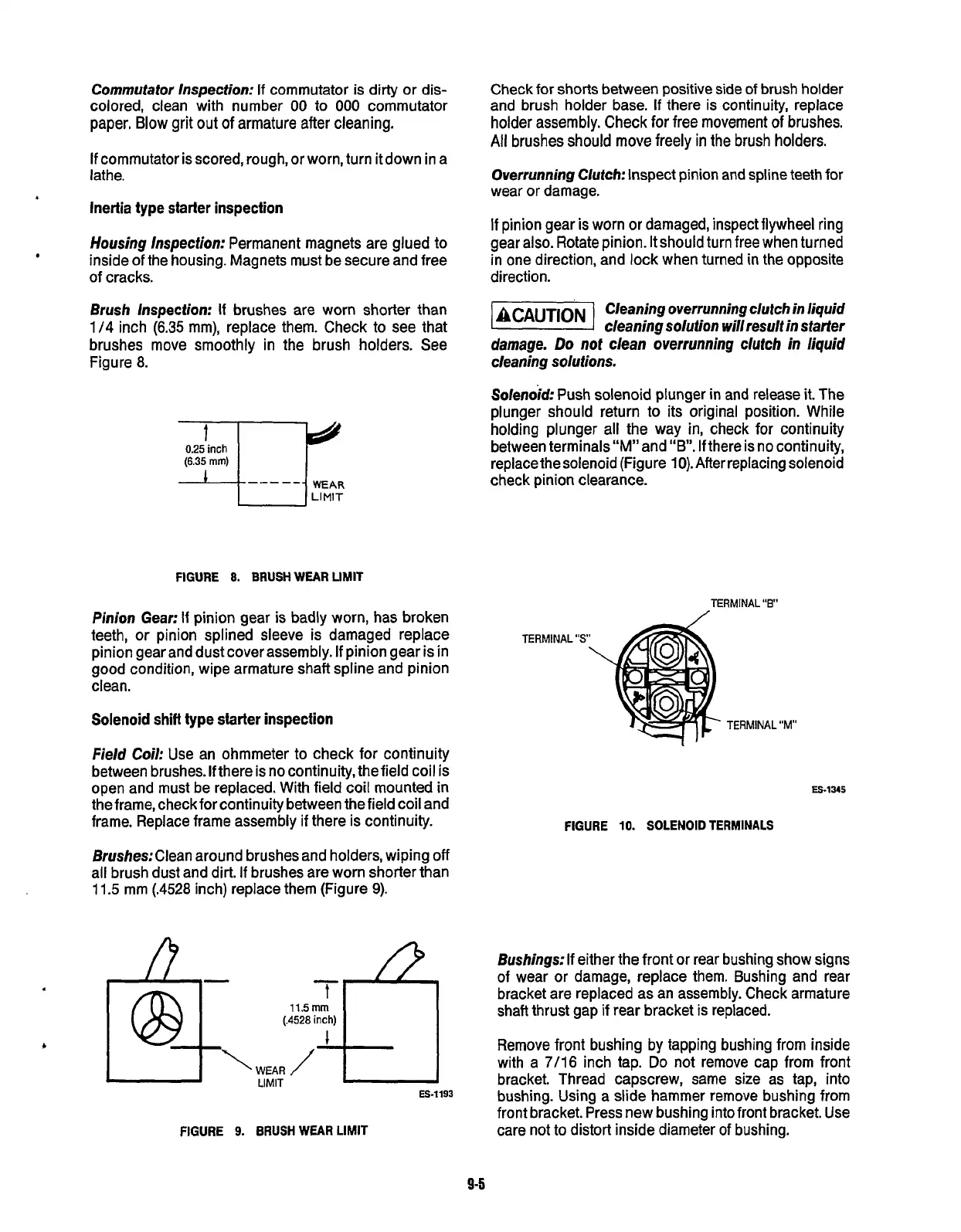

Brush

Inspection:

If

brushes are worn shorter than

1/4

inch

(6.35

mm), replace them. Check to see that

brushes move smoothly in the brush holders. See

Figure

8.

7

0.25

inch

f

Check

for

shorts between positive side

of

brush holder

and brush holder base.

If

there is continuity, replace

holder assembly. Check for free movement of brushes.

All

brushes should move freely

in

the brush holders.

Overrunning Clutch:

Inspect pinion

and

spline teeth for

wear or damage.

If

pinion gear is worn or damaged, inspect flywheel ring

gear also. Rotate pinion. It should turn free when turned

in one direction, and lock when turned in the opposite

direction.

ACAUT~ON

Cleaning overrunning clutch in liquid

m

cleaning solution will result in starter

damage.

Do

not clean overrunning clutch in liquid

cleaning solutions.

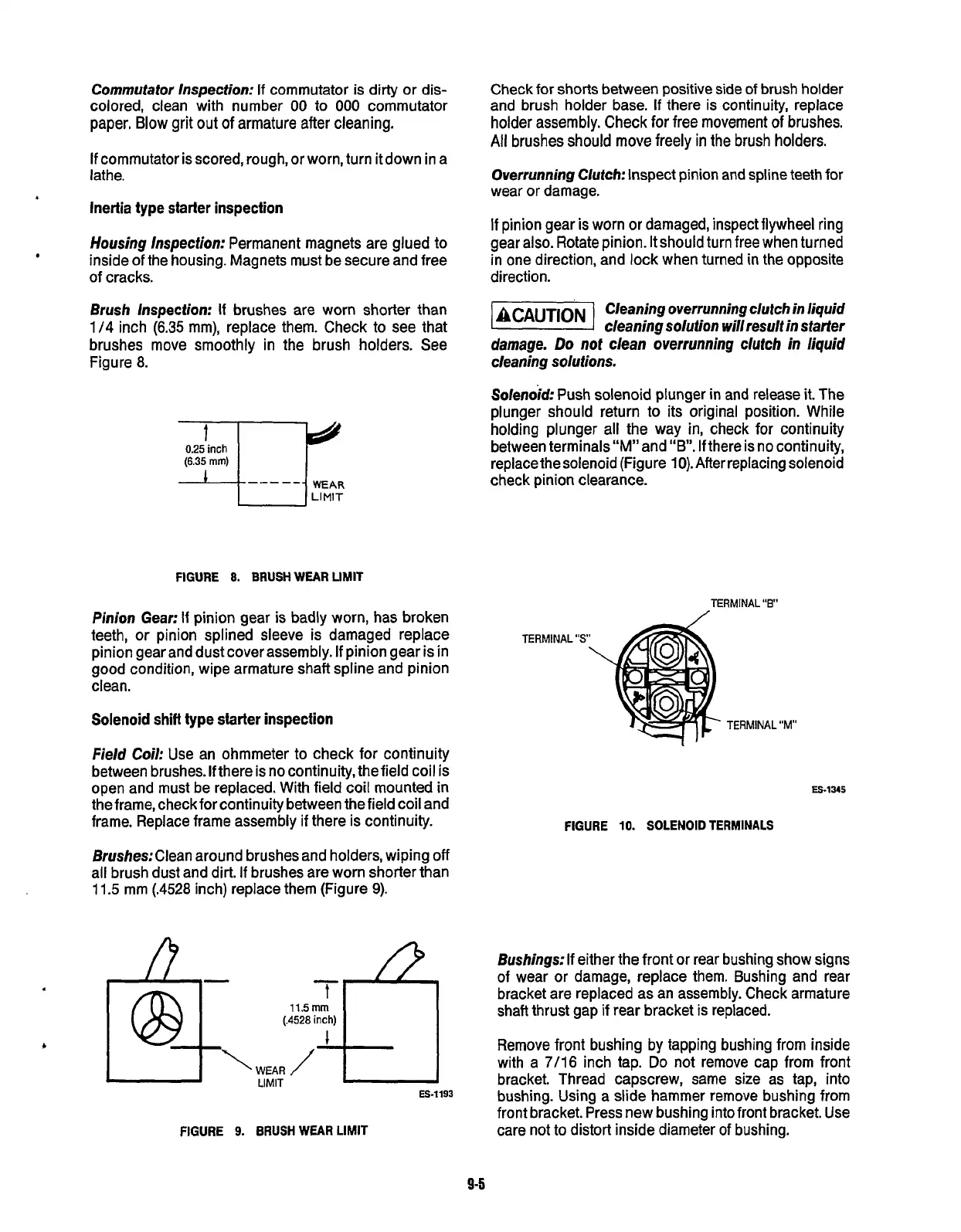

Solenoid:

Push solenoid plunger in and release it. The

plunger should return to its original position. While

holding plunger

all

the way in, check for continuity

between terminals

"M"

and

"B'.

If

there is no continuity,

replace thesolenoid (Figure

10).

After replacing solenoid

check pinion clearance.

FIGURE

8.

BRUSH

WEAR

LIMIT

TERMINAL'W'

Pinion Gear:

If

pinion gear is badly worn, has broken

pinion gear and dust cover assembly. If pinion gear is in

good condition, wipe armature shaft spline and pinion

clean.

teeth, or pinion splined sleeve is damaged replace

TERMINAL'Y

Solenoid

shifl

type starter inspection

TERMINAL

"M"

Field

Coil:

Use an ohmmeter to check for continuity

between brushes.

If

there is no continuity, the field coil is

open and must be replaced. With field coil mounted

in

the frame, check for continuity between the field

coil

and

frame. Replace frame assembly if there is continuity.

Es-1345

FIGURE

10.

SOLENOID TERMINALS

f3rushes:Clean around brushes and holders, wiping

off

all brush dust and dirt.

If

brushes are worn shorter than

11.5

mm

(.4528

inch) replace them (Figure

9).

Bushings:

If either the front or rear bushing show signs

of wear or damage, replace them. Bushing and rear

bracket are replaced as an assembly. Check armature

shaft thrust gap if rear bracket is replaced.

Remove front bushing by tapping bushing from inside

with a

7/16

inch tap.

Do

not remove cap from front

bracket. Thread capscrew, same size as tap, into

bushing. Using a slide hammer remove bushing from

front bracket. Press new bushing into front bracket.

Use

(.4528

inch)

\

WEAR

/

ES-1193

p$q-

LlMlT11*5:fi

FIGURE

9.

BRUSH

WEAR

LIMIT

care not to distort inside diameter of bushing.

9-5

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...