PISTON

ASSEMBLY

Lubricate all parts with engine oil.

Position piston on its respective rod and install the

pin.

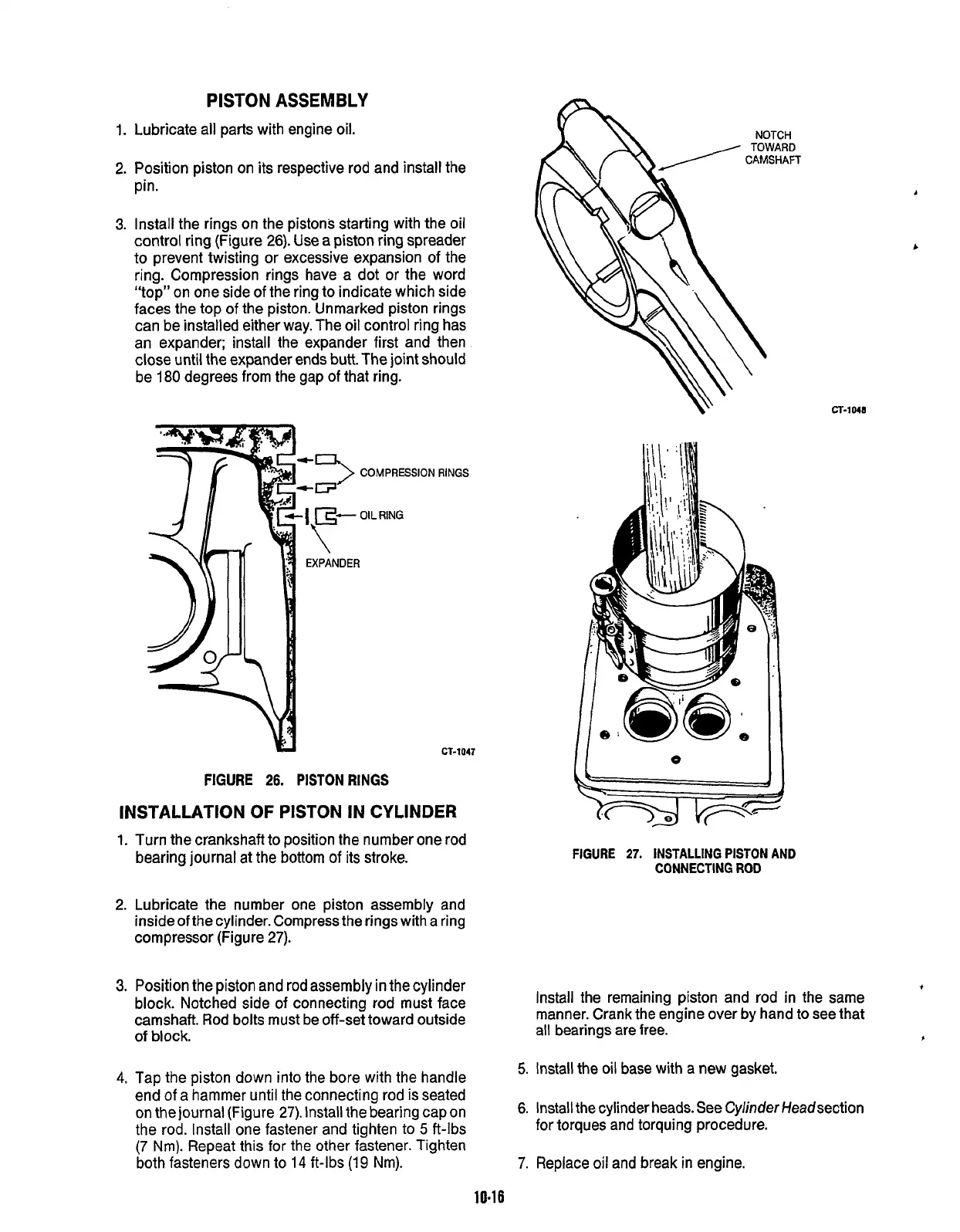

Install the rings on the pistons starting with the oil

control ring (Figure

26).

Use

a piston ring spreader

to

prevent twisting or excessive expansion of the

ring. Compression rings have a dot or the word

“top” on one side of the ring to indicate which side

faces the top

of

the piston. Unmarked piston rings

can be installed either way. The oil control ring has

an expander; install the expander first and then

close until the expander ends butt. The joint should

be

180

degrees from the gap

of

that ring.

CT-1047

FIGURE

26.

PISTON

RINGS

INSTALLATION

OF

PISTON

IN CYLINDER

1.

2.

3.

4.

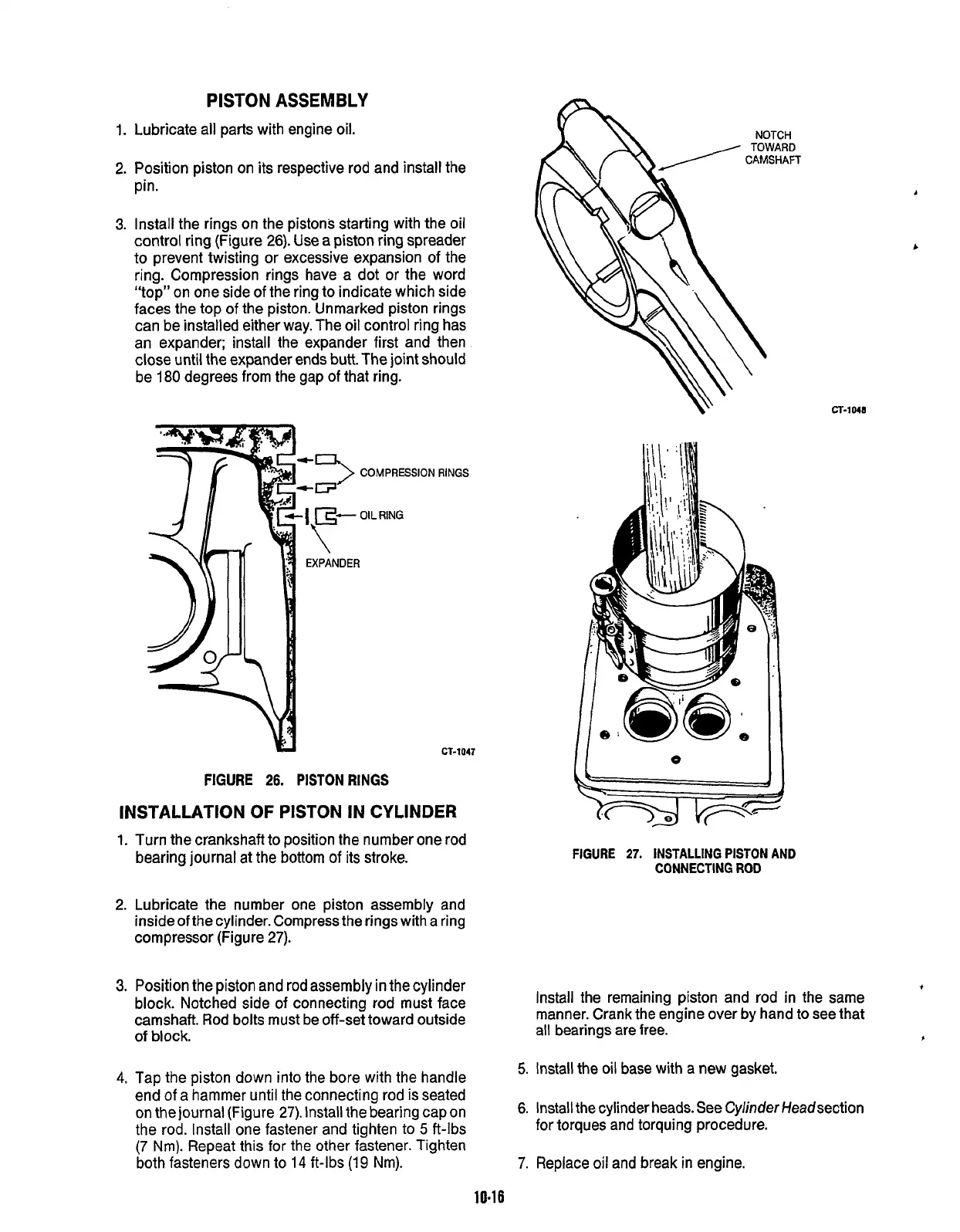

Turn the crankshaft to position the number one rod

bearing journal

at

the bottom

of

its

stroke.

FIGURE

27.

INSTALLING PISTON

AND

CONNECTING

ROD

Lubricate the number one piston assembly and

inside

of

the cylinder. Compress the rings with a ring

compressor (Figure

27).

Position the piston and rod assembly in the cylinder

block. Notched side

of

connecting rod must face

camshaft. Rod bolts must be off-set toward outside

of

block.

P

t

Install the remaining piston and rod in the same

manner. Crank the engine over by hand to see that

all bearings are free.

5.

Install the oil base with a new gasket.

6.

Install the cylinder heads. See Cylinder Headsection

Tap the piston down into the bore with the handle

end of a hammer until the connecting rod is seated

on the journal (Figure

27).

Install the bearing cap on

the rod. Install one fastener and tighten to

5

ft-lbs

(7

Nm).

Repeat this for the other fastener. Tighten

both fasteners down to

14

ft-lbs

(1

9

Nm).

for torques and torquing procedure.

7.

Replace

oil

and break in engine.

10-1

6

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...