After allowing three to four minutes for drying, apply the

Locktitefrom the small tube to the mating surfaces

of

the

bearing and the bearing bore. Align the oil holes in the

bearing with the oil holes in the bearing bore (Fig-

ure 22). The oil passage should be at least half open.

Install the bearing flush with the block, using the combi-

nation driver. Wipe

off

any exesss Locktite around the

bearing. Allow at least one hour for hardening at room

temperatu re.

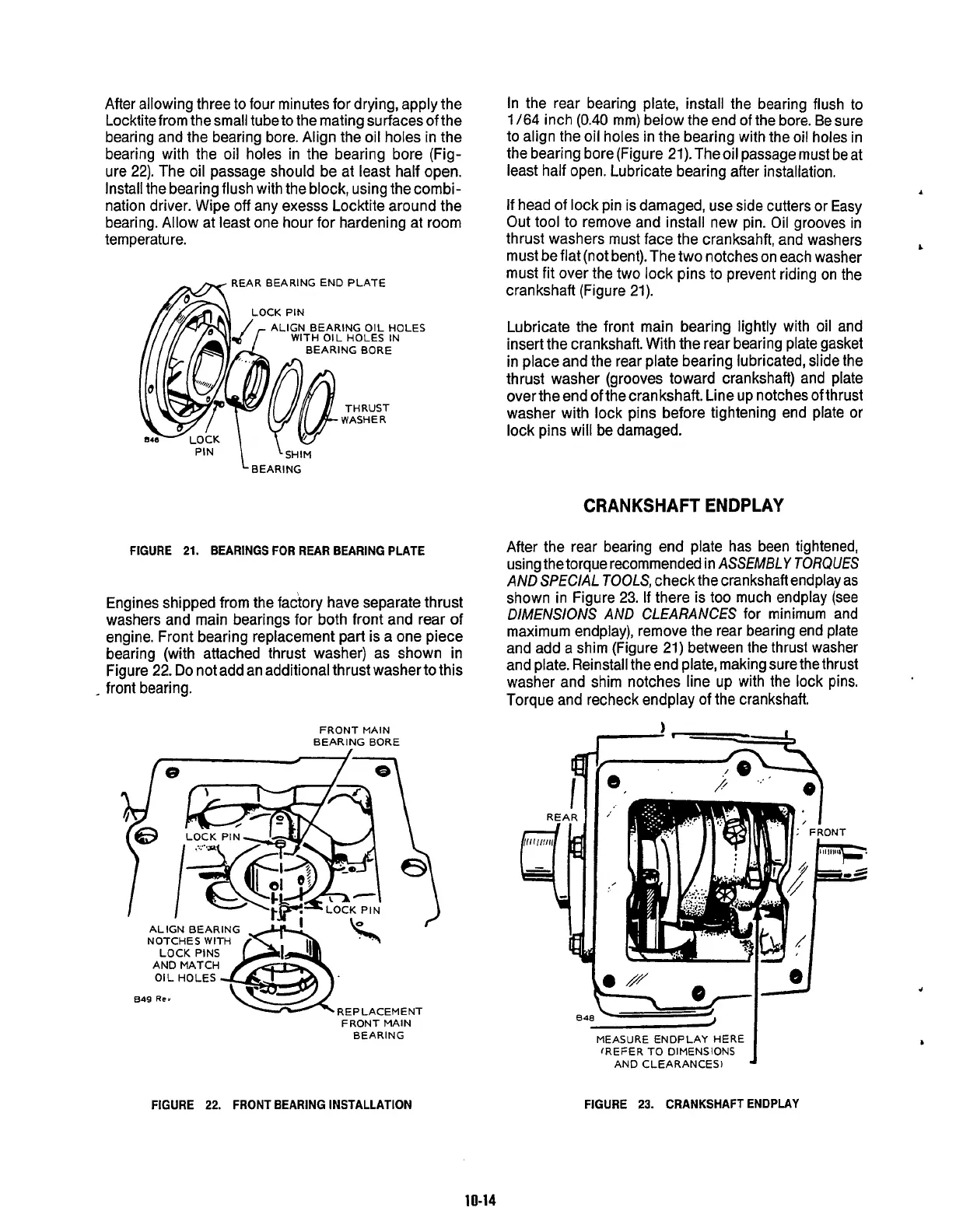

REAR BEARING END PLATE

ALIGN BEARING

OIL

HOLES

WITH OIL HOLES IN

BEARING BORE

THRUST

WASHER

In the rear bearing plate, install the bearing flush to

1

/64

inch

(0.40

mm) below the end of the bore. Be sure

to align the

oil

holes in the bearing with the oil holes in

the bearing bore(Figure 21). The oil passage must be at

least half open. Lubricate bearing after installation.

If

head of lock pin is damaged, use side cutters or Easy

Out

tool

to

remove and install new pin. Oil grooves in

thrust washers must face the cranksahft, and washers

must be flat (not bent). The two notches on each washer

must fit over the two lock pins

to

prevent riding on the

crankshaft (Figure 21).

Lubricate the front main bearing lightly with oil and

insert the crankshaft. With the rear bearing plate gasket

in place and the rear plate bearing lubricated, slide the

thrust washer (grooves toward crankshaft) and plate

overtheendofthecrankshaft. Line up notches ofthrust

washer with lock pins before tightening end plate or

lock pins will be damaged.

CRANKSHAFT

ENDPLAY

FIGURE

21.

BEARINGS

FOR

REAR BEARING PLATE

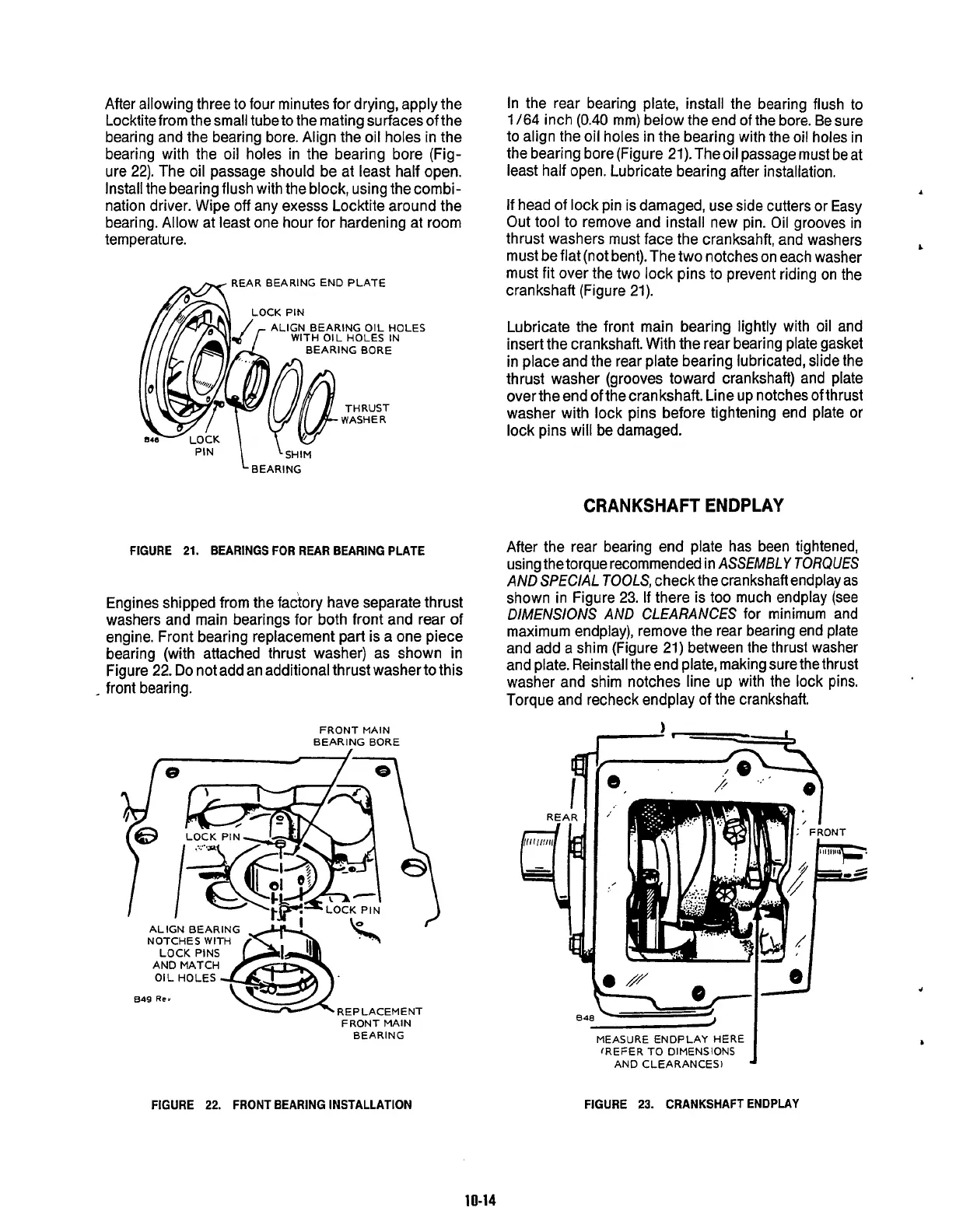

Engines shipped from the factory have separate thrust

washers and main bearings for both front and rear of

engine. Front bearing replacement part is a one piece

bearing (with attached thrust washer) as shown in

Figure 22.

Do

not add an additional thrust washer

to

this

front bearing.

FRONT MAIN

BEARING BORE

1

IENT

FRONT MAIN

BEARING

FIGURE

22.

FRONT

BEARING INSTALLATION

After the rear bearing end plate has been tightened,

using the torque recommended in

ASSEMBLY TORQUES

AND SPECIAL

TOOLS,

check the crankshaft endplayas

shown in Figure 23.

If

there is

too

much endplay (see

DlMENSlONS AND CLEARANCES

for minimum and

maximum endplay), remove the rear bearing end plate

and add a shim (Figure

21)

between the thrust washer

and plate. Reinstall the end plate, making sure the thrust

washer and shim notches line up with the lock pins.

Torque and recheck endplay

of

the crankshaft.

1

MEASURE ENDPLAY HERE

(REFER TO DIMENSIONS

AND CLEARANCES)

FIGURE

23.

CRANKSHAFT ENDPLAY

10-14

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...