Checking Bearing Clearance

With

Plastigauge

The

most

accurate

means

of

determining

bearing

clearance is

by

using micrometers. However,

if

crank-

shaft

is

installed in engine, bearing clearance may be

measured by using a plastic strip (Plastigauge) manu-

factured for this purpose.

1, Make certain that all parts are marked or identified

so

that they are reinstalled in their original positions.

using aclean dry cloth, thoroughly clean all oil from

crankshaft journal and connecting rod.

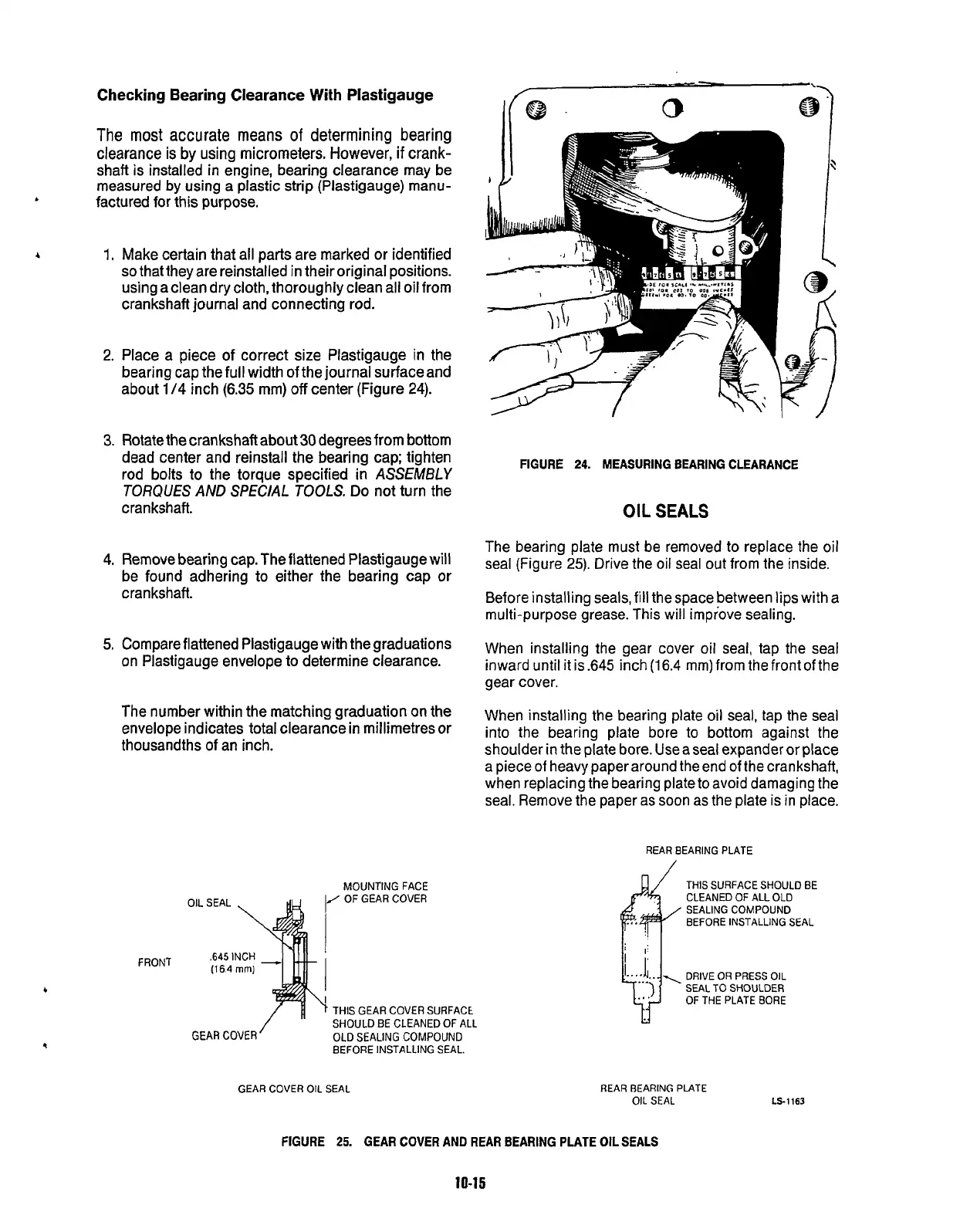

2.

Place a piece

of

correct size Plastigauge in the

bearing cap the full width

of

the journal surfaceand

about

1

/4 inch

(6.35

rnrn)

off

center (Figure 24).

3.

Rotatethe crankshaft about30 degreesfrom bottom

dead center and reinstall the bearing cap; tighten

rod bolts

to

the torque specified in

ASSEMBLY

TORQUES

AND

SPEClAL

TOOLS.

Do

not turn the

crankshaft.

FIGURE

24.

MEASURING BEARING CLEARANCE

OIL

SEALS

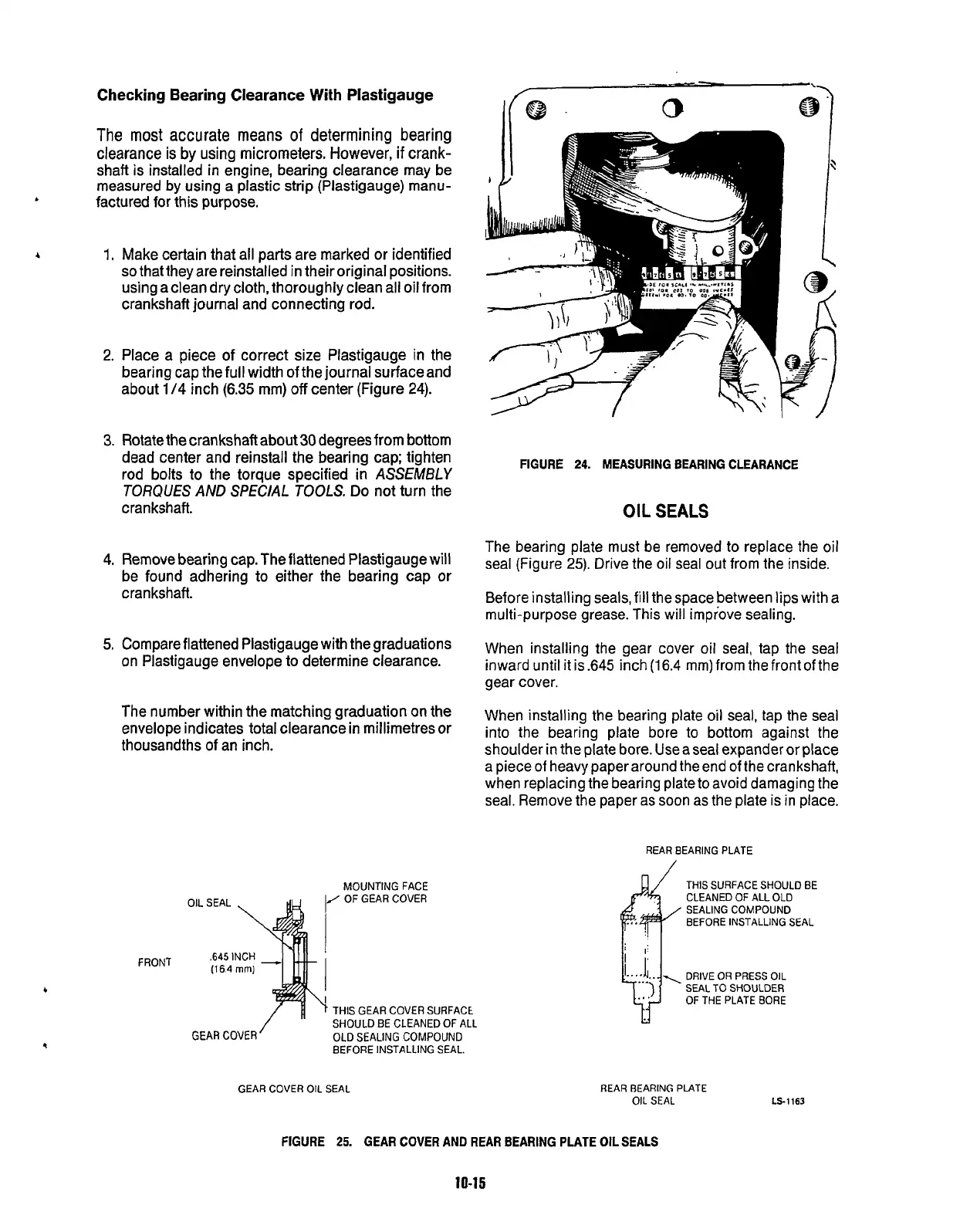

The bearing plate must be removed

to

replace the oil

seal (Figure 25). Drive the oil seal out from the inside.

Before installing seals, fill thespace between lips with a

multi-purpose grease. This will impiove sealing.

When installing the gear cover oil seal, tap the seal

inward until it is .645 inch

(1

6.4 mm) from the front

of

the

gear cover.

When installing the bearing plate oil seal, tap the seal

into the bearing plate bore

to

bottom against the

shoulder in the

plate

bore. Use a seal expander

or

place

a piece of heavy paperaround theend of thecrankshaft,

when replacing the bearing plate

to

avoid damaging the

seal. Remove the paper as soon

as

the plate is in place.

4. Remove bearing cap.Theflauened Plastigaugewill

be found adhering

to

either the bearing cap or

crankshaft.

5-

Compare flattened

Plastigaugewiththegraduations

on Plastigauge envelope to determine clearance.

The number within the matching graduation on the

envelope indicates total clearance in millirnetres or

thousandths of an inch.

MOUNTING FACE

/

OF

GEAR COVER

FRONT

,645

INCH

THIS GEAR COVER SURFACL

SHOULD BE CLEANED OF ALL

OLD SEALING COMPOUND

BEFORE INSTALLING SEAL.

REAR BEARING PLATE

THIS SURFACE SHOULD BE

CLEANED OF ALL

OLD

SEALING COMPOUND

BEFORE INSTALLING SEAL

1

DRIVE

OR

PRESS

OIL

SEAL TO SHOULDER

OF THE PLATE BORE

u

GEAR COVER

OIL

SEAL

REAR

REARING

PLATE

OIL

SEAL

LS-1163

FIGURE

25.

GEAR COVER AND REAR BEARING PLATE

OIL

SEALS

10-15

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...