Brush Repkcement:

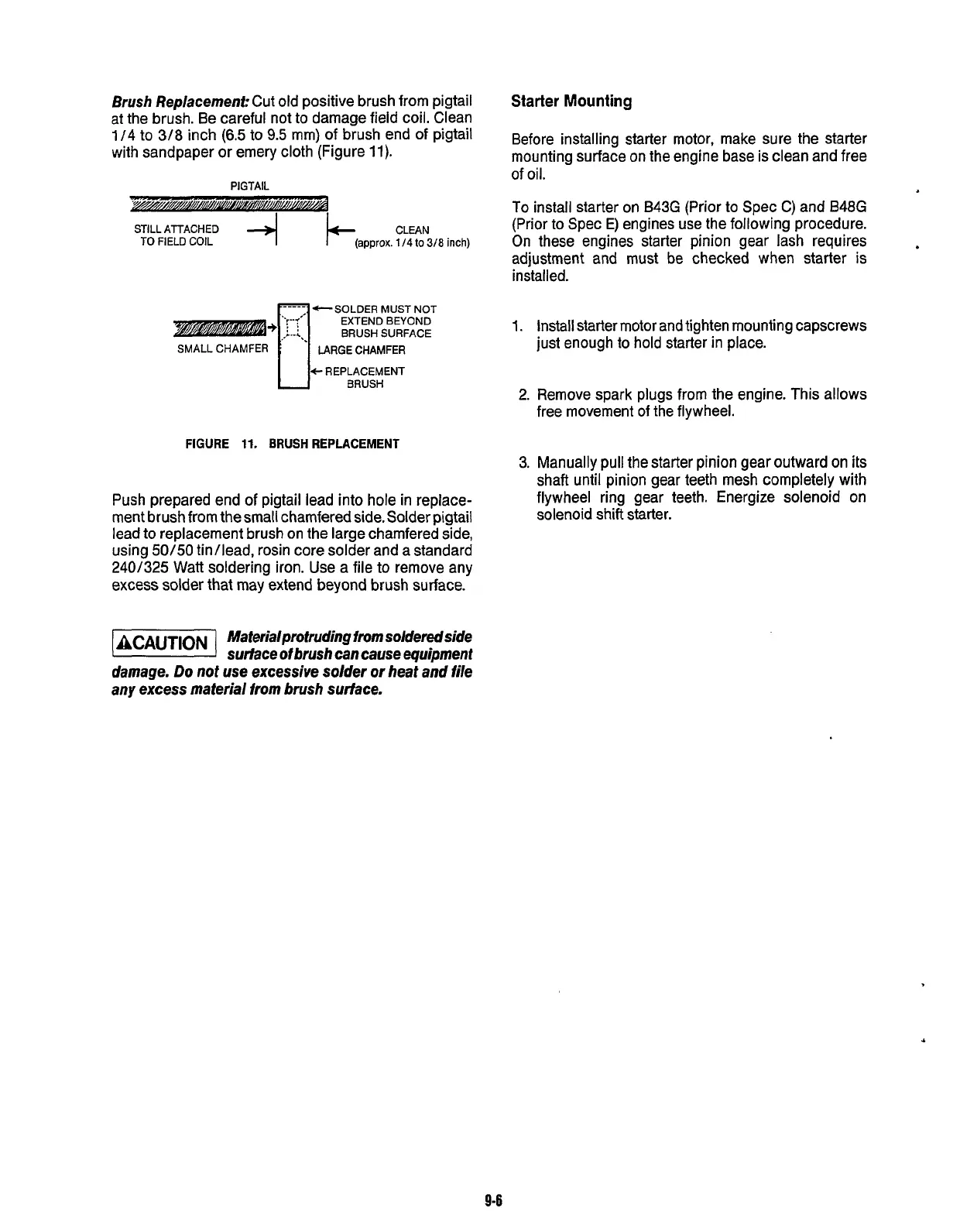

Cut old positive brush from pigtail

at the brush. Be careful not to damage field coil. Clean

1

/4

to

3/8

inch

(6.5

to

9.5

mm)

of

brush end

of

pigtail

with sandpaper or emery cloth (Figure

11).

PIGTAIL

Starter

Mounting

Before installing starter motor, make sure the starter

mounting surface on the engine base is clean and free

of oil.

STILL ATTACHED

4

CLEAN

TO FIELD COIL

(approx.

114

to

3/8

inch)

_____

EXTEND BEYOND

BRUSH SURFACE

*ncSoLDER

..,..:.’

MUST

LARGE CHAMFER

f

REPLACEMENT

U

BRUSH

SMALL CHAMFER

FIGURE

11.

BRUSH REPLACEMENT

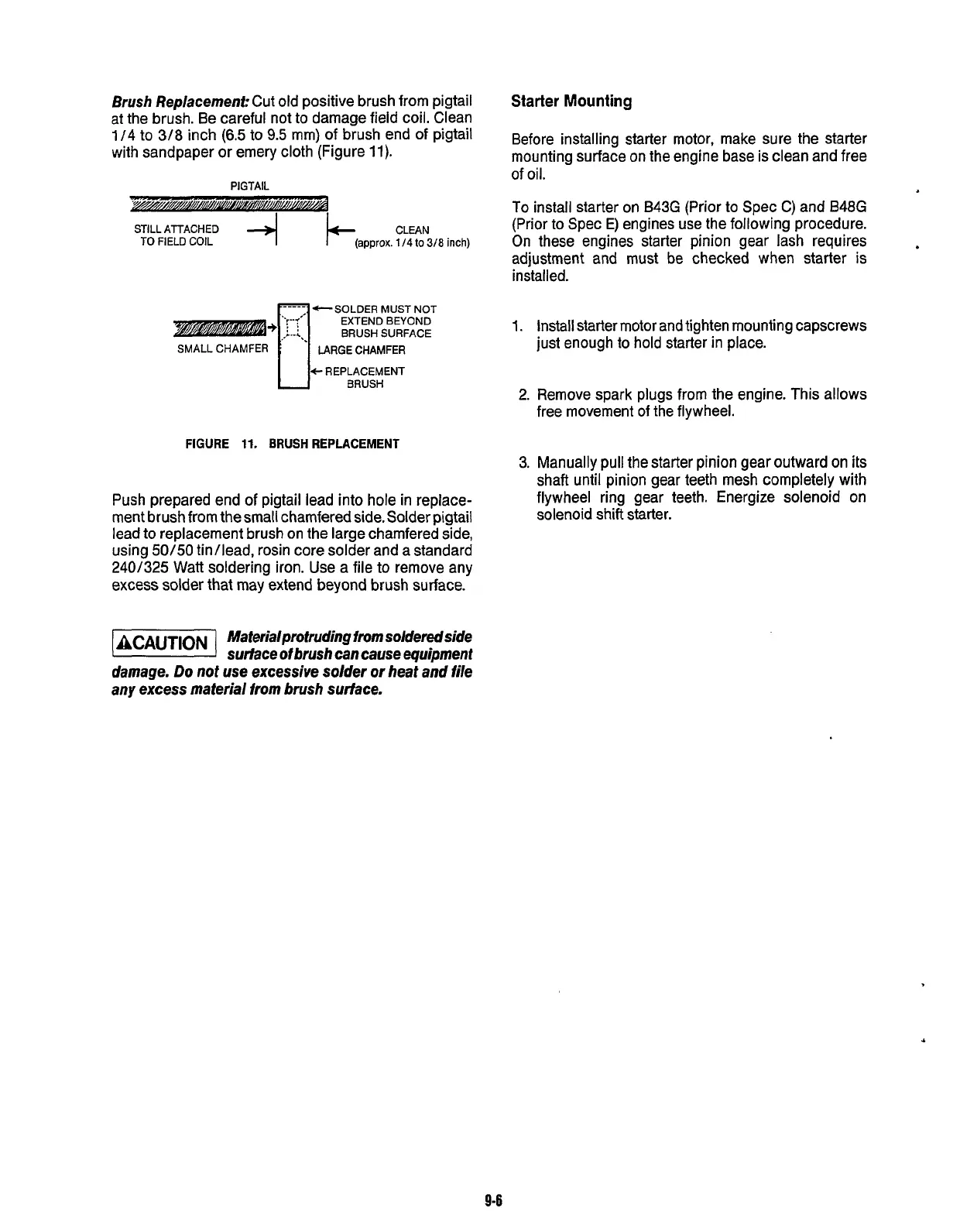

Push prepared end

of

pigtail lead into hole in replace-

ment brush from the small chamfered side. Solder pigtail

lead to replacement brush on the large chamfered side,

using

50/50

tinllead, rosin core solder and a standard

240/325 Watt soldering iron. Use a file to remove any

excess solder that may extend beyond brush surface.

To

install starter on B43G (Prior to Spec

C)

and B48G

(Prior to Spec E) engines use the following procedure.

On these engines starter pinion gear lash requires

adjustment and must be checked when starter is

installed.

1.

Install starter

motor

and tighten mounting capscrews

just enough to hold starter in place.

2.

Remove spark plugs from the engine. This allows

free movement of the flywheel.

3. Manually pull the starter pinion gear outward

on

its

shaft until pinion gear teeth mesh completely with

flywheel ring gear teeth. Energize solenoid on

solenoid shift starter.

(BCAUTIONI

Ma ferial protruding

from

solderedside

sudace

of

brush can cause equipment

damage.

Do

not use excessive solder

or

heat

and

file

any excess material from brush surface.

9-6

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...