PULSATING-DIAPHRAGM FUEL PUMP

Pulsating diaphragm fuel pumps, or pulse pumps, rely

on changes in crankcase vacuum to create a pulsating

movement of the pump diaphragm.

As

the engine’s

pistons move outward, a vacuum is created. This

vacuum is transmitted to the pump diaphragm, causing

it

to

pull back and suck fuel into the pump.

As

the

engine’s pistons move inward, crankcase vacuum is

reduced and the diaphragm return spring pushes the

pump diaphragm forward, forcing fuel through the

pump outlet.

Fuel Pump

Test

Procedure

Before testing make certain that fuel pump vacuum line

connections are tight and free of leaks.

1.

Operate engine at an idle for five minutes to ensure

that carburetor is full of fuel.

2.

Shut engine

off

and remove fuel inlet line from fuel

Pump.

71

Ignition of fuel can result in

severe personal injury or death.

Thoroughly clean up any spilled fuei

piece of fuel hose with clamps.

Record vacuum gauge reading.

3.

Connect a vacuum gauge tofuel pump inlet using a

4.

Start engine and allow to idle for five seconds.

5.

6.

7.

8.

9.

10.

Move throttle control to high idle position. Wait five

seconds and record vacuum gauge reading.

Shut engine

off

and remove vacuum gauge hose

from fuel pump inlet. Connect fuel inlet line to fuel

pump.

Remove fuel outlet line from fuel pump.

-1

Ignition

of

fuel can result in

severe personal iniurv or death.

Thoroughly clean up any spilled fuei

Connect a pressure gauge tofuel pump outlet using

a piece of fuel hose with clamps.

Start engineand allow to idle for five seconds. While

holding pressure gauge level with pump outlet

record pressure gauge reading.

Move throttle control to high idle position and allow

engine to run for five seconds. While holding

pressure gauge level with pump outlet record

pressure gauge reading.

11.

Shut engine

off

and remove pressure gauge hose

from fuel pump outlet. Connect fuel outlet line to fuel

pump.

Repair or replace the fuel pump

if

test readings are not

within the values specified

in

TABLE

1.

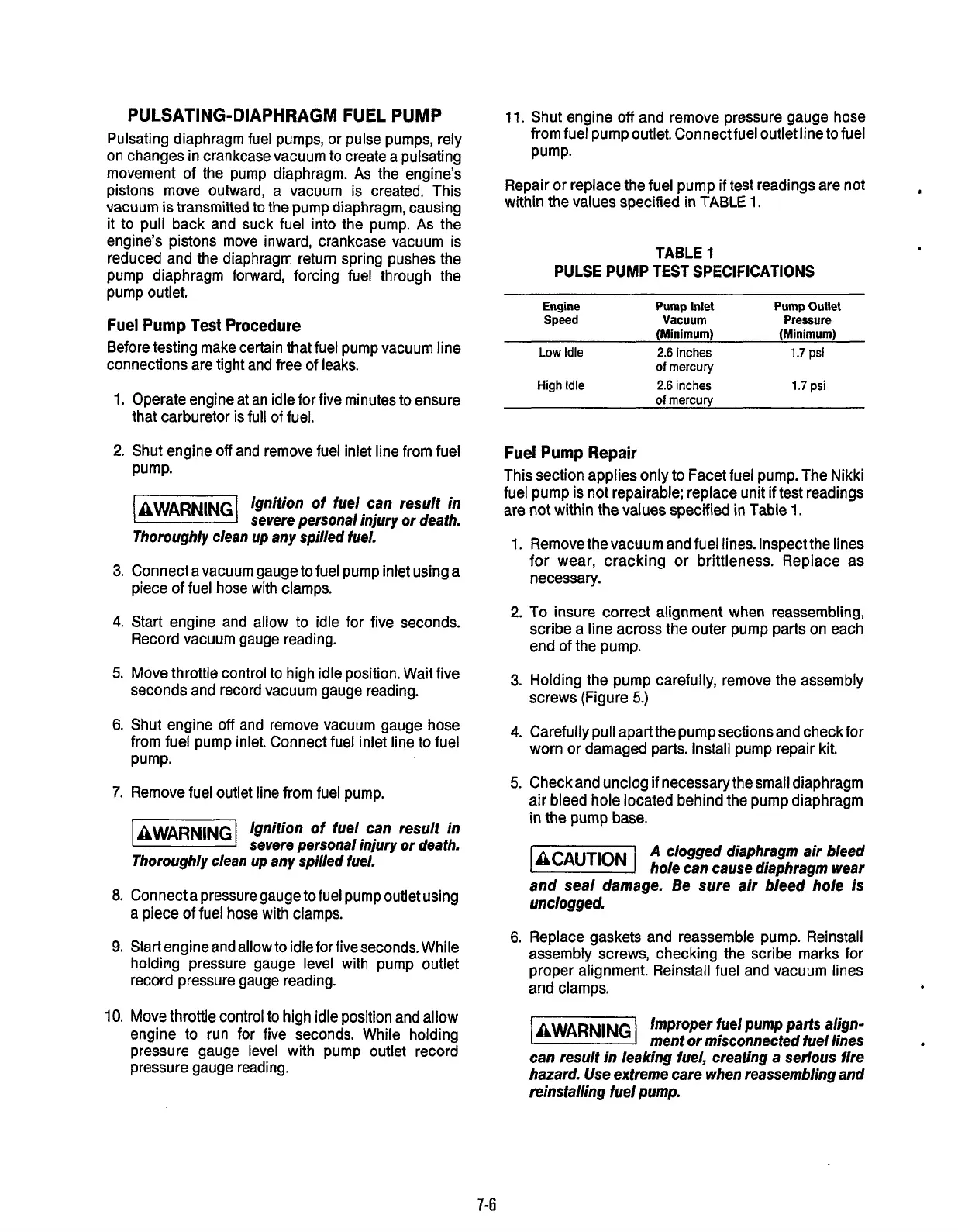

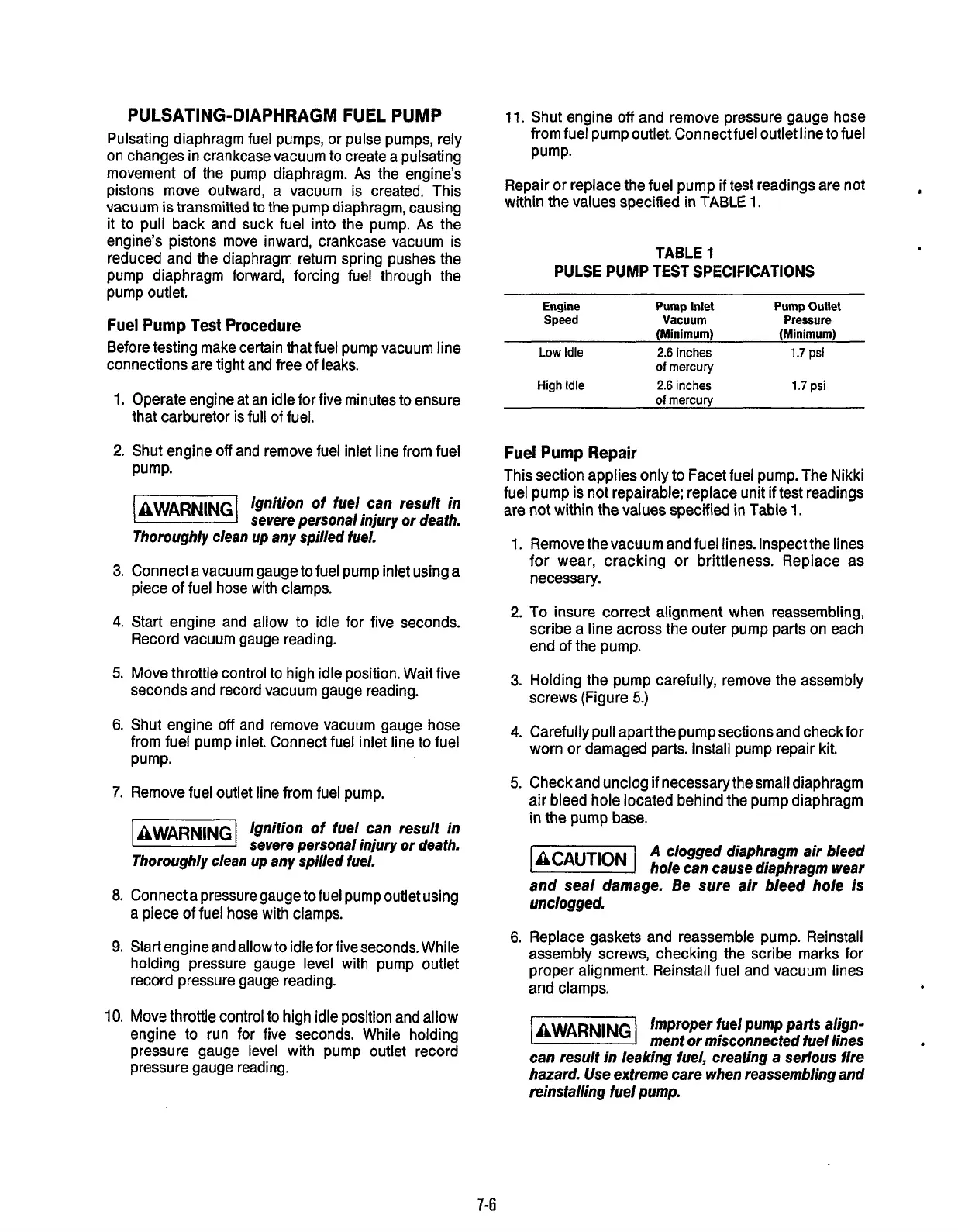

I

TABLE

1

PULSE PUMP TEST SPECIFICATIONS

Engine

Pump

Inlet

Pump

Outlet

Pressure

Speed

Vacuum

(Minimum) (Minimum)

Low

Idle

2.6

inches

1.7

psi

of

mercury

High

Idle

2.6

inches

1.7

psi

of

mercury

Fuel Pump Repair

This section applies only to Facet fuel pump. The Nikki

fuel pump is not repairable; replace unit

if

test readings

are not within the values specified in Table

1.

1.

Remove thevacuum and fuel lines. Inspect the lines

for wear, cracking or brittleness. Replace as

necessary.

2.

To insure correct alignment when reassembling,

scribe a line across the outer pump parts on each

end of the pump.

3.

Holding the pump carefully, remove the assembly

screws (Figure

5.)

4.

Carefully pull apart the pump sections and check for

worn

or

damaged parts. Install pump repair kit.

5.

Check and unclog

if

necessary the small diaphragm

air bleed hole located behind the pump diaphragm

in the pump base.

A

clogged diaphragm air bleed

ACAUTION

hole can cause diaphragm wear

and seal damage. Be sure air bleed hole

is

unclogged.

6.

Replace gaskets and reassemble pump. Reinstall

assembly screws, checking the scribe marks for

proper alignment. Reinstall fuel and vacuum lines

and clamps.

1

[-I

Improper fuel pump

parts

align-

ment

or

misconnected fuel lines

can result in leaking fuel, creafing a serious fire

hazard. Use extreme care when reassembling and

reinstalling fuel pump.

7-6

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...