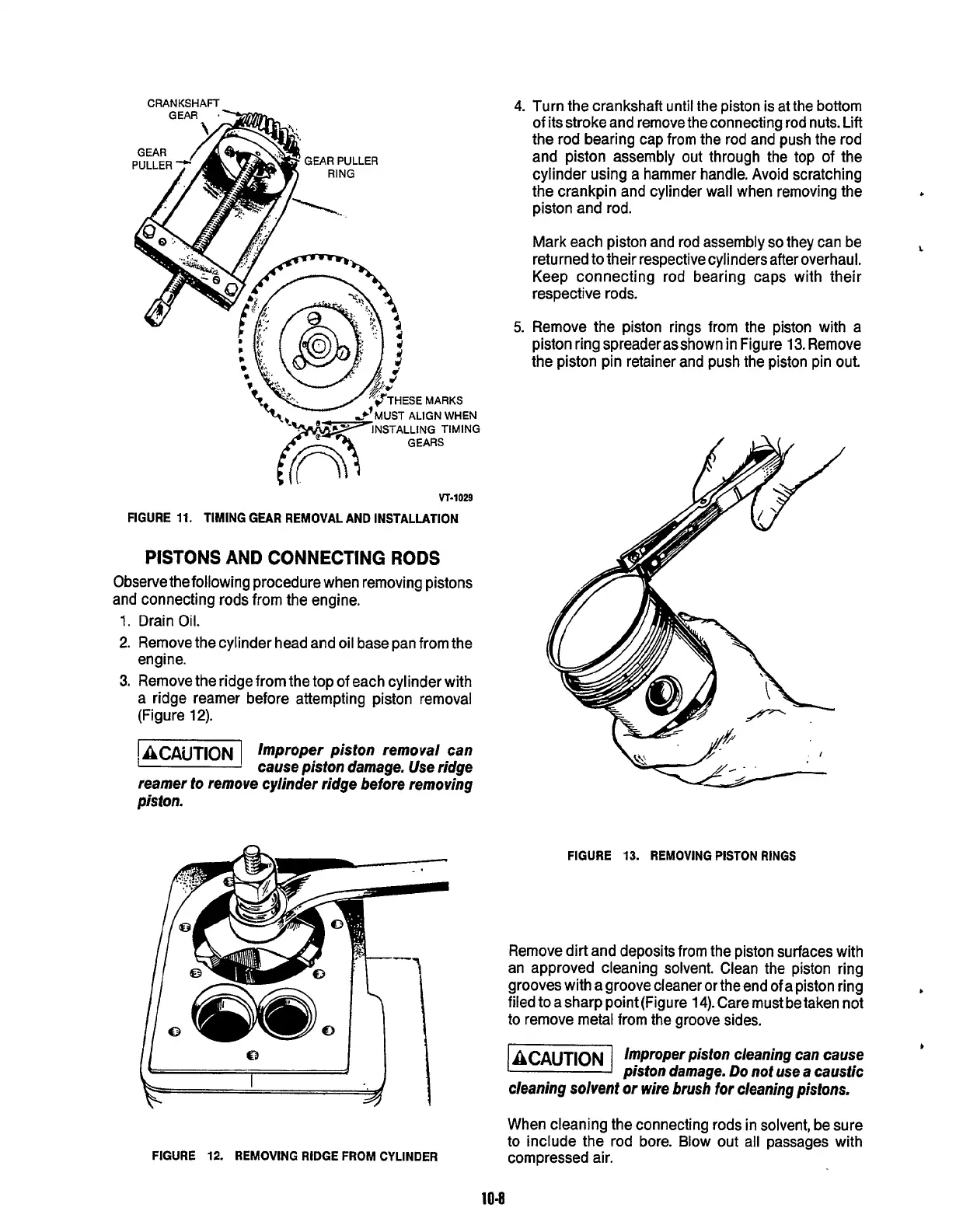

CRANKSHAFT

GEAR

PULLER

E MARKS

LIGN WHEN

ING TIMING

EARS

VT-1029

FIGURE

11.

TIMING

GEAR

REMOVAL

AND

INSTALLATION

PISTONS AND CONNECTING RODS

Observe the following procedure when removing pistons

and connecting rods from the engine.

1.

Drain Oil.

2.

Remove the cylinder head and oil base pan from the

engine.

3.

Remove the ridge from the top of each cylinder with

a ridge reamer before attempting piston removal

(Figure

12).

1-

Improper piston removal can

cause piston damage. Use ridge

reamer to remove cylinder ridge before removing

piston.

FIGURE

12.

REMOVING

RIDGE

FROM

CYLINDER

4. Turn the crankshaft until the piston is at the bottom

of its stroke and remove the connecting rod nuts. Lift

the rod bearing cap from the rod and push the rod

and piston assembly out through the top of the

cylinder using a hammer handle. Avoid scratching

the crankpin and cylinder wall when removing the

piston and rod.

Mark each piston and rod assembly

so

they can be

returned to their respectivecylinders after overhaul.

Keep connecting rod bearing caps with their

respective rods.

L

L

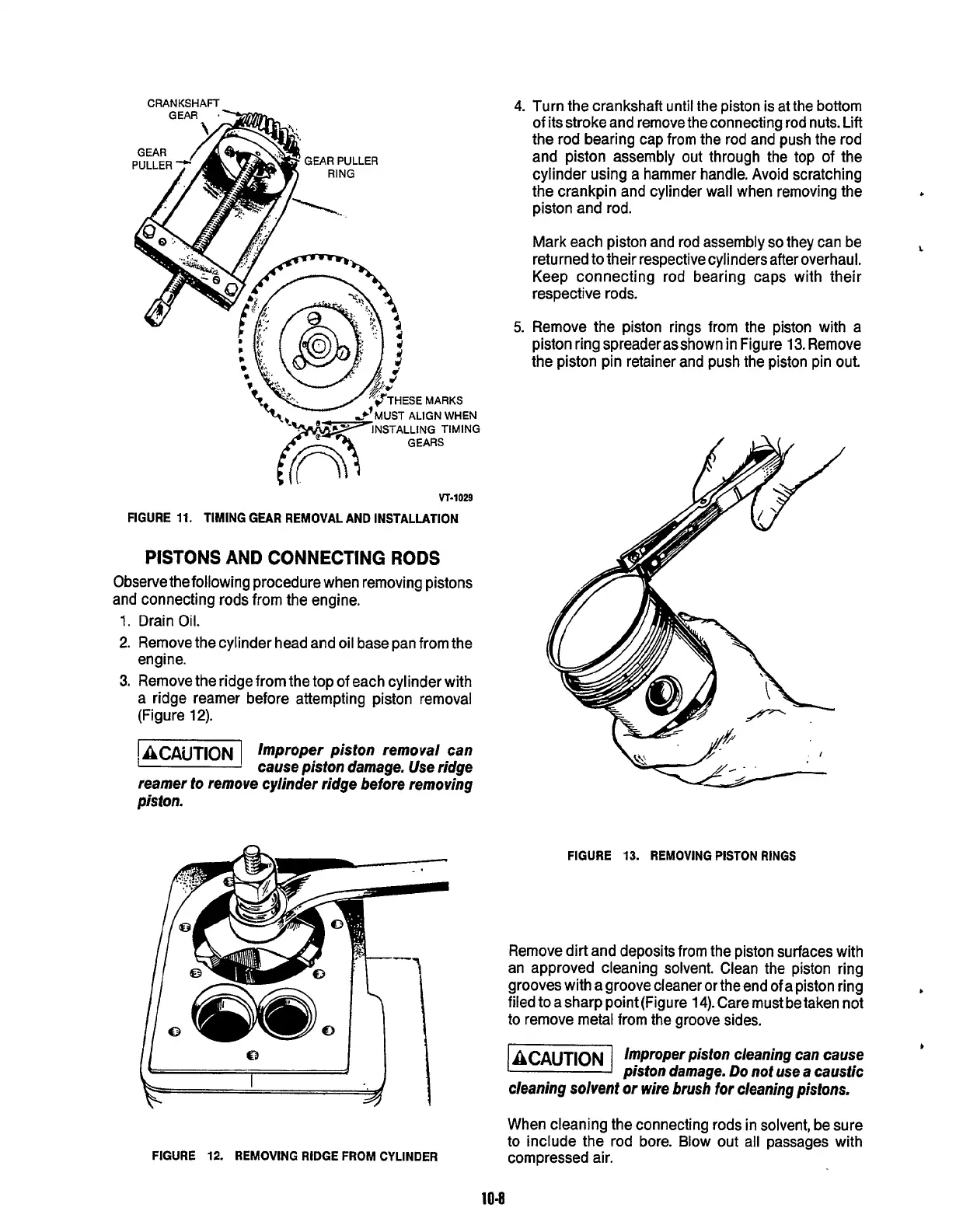

5.

Remove the piston rings from the piston with a

piston ring spreader asshown in Figure 13. Remove

the piston pin retainer and push the piston pin out.

FIGURE

13.

REMOVING

PISTON

RINGS

Remove dirt and deposits from the piston surfaces with

an approved cleaning solvent. Clean the piston ring

grooves with agroove cleaner or the end

of

a piston ring

filed to a sharp point (Figure 14). Care must be taken not

to remove metal from the groove sides.

ACAUT~ON

Improper pisfon cleaning can cause

m

piston damage.

Do

nof use a caustic

cleaning solvent

or

wire

brush

for

cleaning pistons.

When cleaning the connecting rods in solvent, be sure

to include the rod bore.

Blow

out all passages with

compressed air.

104

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...